On November 14, according to the news released by Panjin, Panjin Sanli Zhongke New Materials Co., Ltd. has an annual output of 100000 tons of new materials production project site, the main construction has been completed, and all-round finishing work is being carried out in full swing, and equipment commissioning is about to enter the trial production stage.

Its core technology is ethylene three-step legal MMA developed by Dalian Institute of Chemistry, Chinese Academy of Sciences, which is the first in China and the leading international level. MMA is an important chemical raw material, widely used in aerospace, medical, optical and other high-tech fields, the market prospect is broad. According to the person in charge of the enterprise, the smooth transformation of the new achievements from the laboratory to the production line benefits from the all-round guarantee and support of the Panjin fine chemical pilot base in Liaoning Province, from the factory building, warehouse to talents and technology, so as to realize the leap of "Darwin Dead Sea.

It is understood that the project will start construction in the west expansion area of Panjin Fine Chemical Industry Development Zone in January 2022. The total investment of the project is 2.1 billion yuan, of which the first phase investment is 1.1 billion yuan, covering an area of 269 mu, with an annual output of 50000 tons of MMA/PMMA and 50000 tons of n-propanol.

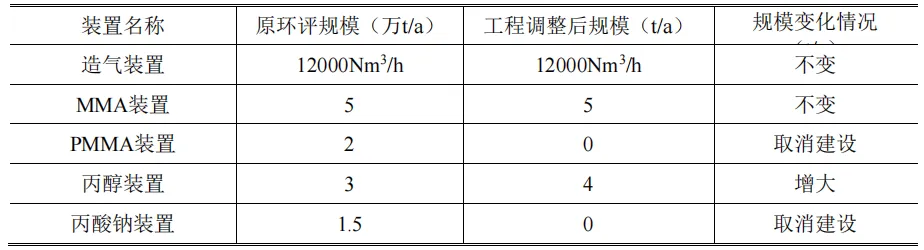

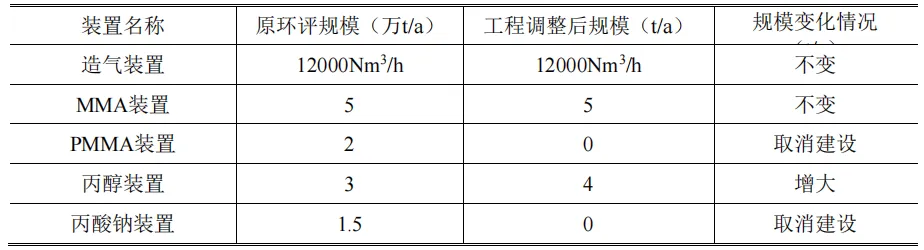

on May 13 this year, the 100000-ton new material production project of Panjin Sanli Zhongke New Materials Co., Ltd. was publicized before the environmental impact report was submitted for approval. The original project plan was adjusted in the EIA. The following are some key information:

construction content and scale: the project will build 12000 Nm3/h gas making device (including 12000 Nm3/h gas making device and 12000 Nm3/h synthesis gas refining device), 50000 tons/year MMA device (including 50000 t/a formaldehyde device and 50000 t/aMMA device), 40000 tons/year n-propanol device (including 80000 t/a propionaldehyde device and 40000 t/a propanol device), etc.

Reason for project change: after the original EIA was approved, sanli company adjusted the project production plan according to the market situation of raw materials and products, retaining only 3 of the 5 sets of production units, including gas making unit, MMA unit and propanol unit, of which the scale of gas making unit and MMA unit remained unchanged, and the scale of normal propanol unit increased from 30000 tons/year to 40000 tons/year. In addition to relying on the construction in progress, the storage and transportation system of this project adds 19 storage tanks with a total capacity of 5000 m3.

Table of changes in project plant scale

MMA main production process

Methyl methacrylate (Methyl methacrylate, MMA) is an important chemical raw material, which can be self-polymerized or copolymerized with other monomers in the presence of photothermal or catalyst. Mainly used in the production of polymethyl methacrylate (PMMA), polyvinyl chloride impact modifier (such as ACR, MBS), can also be used in coatings, adhesives, textile printing and dyeing auxiliaries and other fields, the use is very extensive. There are many synthetic methods of MMA, including acetone cyanohydrin method (ACH method), isobutylene/tert-butanol oxidation method (C4 method), ethylene method (C2 method), methanol-methyl acetate method (C1 method), etc. According to the carbon number of its raw materials, it can be divided into C1 route, C2 route, C3 route and C4 route.

From a global perspective, the most commonly used production process is ACH method, which is relatively mature, stable and simple, accounting for about 61.6 percent of the world's total, mainly concentrated in North America, Western Europe and China. The second is C4 method, which was developed by Japan Catalyst Chemical Industry Company and Mitsubishi Rayon Company in 1982. The process is advanced, with non-toxic and harmless raw materials, less by-product and low cost, accounting for about 30.5 percent of the world's total.

1. Acetone cyanohydrin method (ACH method) there are five routes for the production of MMA from C3 organic matter, namely, acetone cyanohydrin route (ACH), MGC-ACH route, Evonik ACH route, propylene carbonylation route and propyne route.

ACH method is currently the most used MMA production process in the world. It was introduced by ICI Company in 1934 and was first industrialized in 1937. The initial process will produce a large number of ammonium sulfate by-products, after improvement, now more use of sulfuric acid circulation route, that is, the normal state without sulfuric acid and no by-products.

The process route is divided into three processes, the main feature is the effective use of chemical by-product hydrocyanic acid, and high yield of MMA. However, the process device must use acid-resistant equipment, and the raw material hydrocyanic acid is highly toxic, the production process should be strictly controlled.

2. Direct oxidation of isobutylene/tert-butyl alcohol (C4 method) since 1982, many Japanese companies such as Asahi Kasei, Mitsui-Kolli, Mitsubishi Liyang and Japan Methacrylic Acid Monomer Company have successively developed processes for producing MMA from C4 organic compounds, including isobutylene (IB/i-C4), tert-butyl alcohol (TBA) and isobutane.

At present, there are four process routes: three-step direct oxidation of isobutylene/tert-butanol, two-step direct oxidation of isobutylene/tert-butanol, direct esterification and isobutane oxidation. Among them, the source of raw materials for the direct oxidation of isobutylene/tert-butanol is abundant, and foreign technologies have multiple sets of devices in operation, which are more reliable, and domestic technologies have achieved breakthroughs.

The isobutylene/tert-butyl alcohol direct oxidation method is divided into a direct oxidation three-step method and a two-step method according to the reaction process. Among them, the oxidation of MA and the esterification of MAA in the three-step direct oxidation of isobutylene/tert-butanol are completed in one reactor, that is, the two-step direct oxidation of isobutylene/tert-butanol. This process was developed by Asahi Kasei and was first industrialized in 1998. Many companies have developed similar processes.

Compared with the three-step method, the two-step method has low investment, low cost, and avoids the explosion limit problem of the recovery process, which is a technology with economic value. At present, the two-step method has many sets of production equipment, mainly distributed in Japan, China, Singapore, Thailand, South Korea and other Asian countries.

3. Ethylene method (C2 method) there are three routes to produce MMA from ethylene: propionaldehyde process, propionic acid process and methyl propionate process. At present, only the propionaldehyde process and the methyl propionate process have been industrialized.

Propionaldehyde process route is typical of BASF aldehyde process. The route was developed by BASF and industrialised in 1988, with a 36000-ton/year unit in Ludwigshafen. At present, the production technology of this route is monopolized by BASF, and there is no external transfer or joint venture to build MMA devices.

The most commonly used methyl propionate route is the Alpha process. The process was primarily developed by Shell and transferred to Lucite International via ICI. After further development, Lucite industrialized the route in 2006, and built a 120000-ton/year MMA plant on Jurong Island in Singapore in 2008 and a 250000-ton/year MMA plant in Saudi Arabia in 2017.

The Alpha process gets rid of the shortcomings of the traditional ACH method and the isobutylene oxidation method, does not require an acid recovery unit, does not produce MA intermediates, has mild process conditions, does not use toxic or corrosive chemicals, and thus does not require the use of special manufacturing materials and has low maintenance costs.

In recent years, domestic enterprises have invested great enthusiasm in the development of Alpha route, and have made great progress in the development of catalysts and fixed bed reaction processes, but the catalyst life has not yet reached the requirements of industrial applications.

4. Methanol/formaldehyde-methyl acetate method (C1 method)

in recent years, due to overcapacity in the coal chemical industry, the process of synthesizing MMA by coal-based route has attracted the interest of researchers. At present, there are two process routes for producing MMA from C1: formaldehyde-methyl acetate method and methanol-methyl acetate method.

The formaldehyde-methyl acetate process uses formaldehyde and methyl acetate as raw materials to obtain MMA by three-step addition condensation. The route was first developed by Beijing Xuyang Technology Co., Ltd. and the mid-test run was completed in 2018.

Methanol-methyl acetate process takes methanol and methyl acetate as raw materials, methanol is first oxidized to formaldehyde, and formaldehyde and methyl acetate are synthesized to produce MMA through a three-step reaction. Compared with formaldehyde-methyl acetate, the raw material methanol cost is lower, the raw material source is wider, and can be combined with the coal methanol process to form a coal-methanol-MMA integrated route.

The process route was developed by Hubei Sanli Fengxiang Technology Co., Ltd., using coal as raw material, from syngas through methanol to formaldehyde, and then reacted with methyl acetate to produce MMA. In 2020, Xinjiang Zhongyou Puhui Technology Co., Ltd. will use this process to build a 110000-ton/year MMA device in two phases in Hami City, Xinjiang, of which the first phase of the 10000-ton/year MMA device has been delivered in mid-May 2021.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)