Read: 495

Time:29months ago

Source:烯烃产业创新与发展研习社、烯烃及高端下游

on July 24, Sinochem Quanzhou official website made public the draft for environmental impact assessment of 100000 tons/year EVA project of Sinochem Quanzhou Petrochemical Co., Ltd.

Sinochem Quanzhou Petrochemical's existing EVA unit has an approved scale of 200000 tons/year in Sinochem Quanzhou's 1 million tons/year ethylene and oil refining renovation and expansion project, with an actual construction scale of 100000 tons/year and an expanded capacity of 140000 tons/year. This project will build a 100000-ton/year EVA device on another reserved site in Sinochem's plant area, adding 100000-ton/year EVA production scale. After expansion, Sinochem Quanzhou EVA plans to build a total production capacity of 240000-ton/year. on May 11, the ethylene-vinyl acetate resin (EVA) plant, the last set of completed chemical plants in the first phase of the Gulei refining and chemical integration project, achieved a successful safe commissioning, marking that all chemical production plants in Gulei Petrochemical Company were put into operation. EVA device is one of the nine main devices of Gulei refining and chemical integration project. The device uses ethylene as raw material and will produce 300000 tons of ethylene-vinyl acetate resin annually, which can effectively make up for the gap in the domestic EVA market. on February 1, the annual EVA project of 350000 tons of new chemical materials in Quanzhou Quangang Baihong started. It is reported that the total investment of the project is 13.8 billion yuan, and the construction site of the project is located in Nanshan area of Quanzhou Quangang Petrochemical Park. It is planned to complete trial production by the end of December 2024, mainly build 300000 tons/year butane pretreatment, 150000 tons/year n-butane to maleic anhydride, 200000 tons/year CO2 recovery, 200000 tons/year ethylene carbonate, 120000 tons/year methyl ethyl carbonate, 10000 tons/year acetaldehyde recovery, 45000 standard/hour natural gas partial oxidation, 350000 tons/year acetic acid, 100000 tons/year vinyl acetate, 150000 tons/year EVA device (kettle type), 200000 tons/year EVA device (tubular), 250000 tons/year butane pretreatment (including 100000 tons/year isobutane normal structure), 150000 tons/year n-butane to maleic anhydride, 150000 tons/year BDO, 100000 tons/year succinic acid, 50000 tons/year PBS unit, 46000 tons/year polytetrahydrofuran unit, 100000 tons/year propylene carbonate and other 18 units. on November 30, 2022, Jiangsu hongjing new materials co., ltd. will accept the EIA documents for the 500000-ton/year EVA project (phase I), and plan the second phase of the 100000-ton high-end hot melt adhesive EVA project. On October 13, 2022, Jiangsu Hongjing New Materials 200000 tons of photovoltaic grade EVA project, public works and auxiliary facilities project EIA was approved. Regarding the EVA project, the investment amount is 2.585 billion yuan, which is planned to be put into production in October 2024, and it is planned to adopt the Leander Basel (Basell Lupotech T) tubular process. On September 7, 2022, the commencement ceremony of Dongfang Shenghong New Chemical Material Project was held in Lianyungang Petrochemical Base. Shenghong Chemical New Material Project is mainly based on new energy materials, and plans to build 700000 tons/year EVA, PO/SM, polyol, high-end polyolefin and other projects. After the completion of the project, Dongfang Shenghong EVA production capacity will reach 1 million tons/year, of which photovoltaic grade EVA will account for more than 40% of the global market, ranking first in the world. on September 27, 2022, the National Energy Group held a centralized commencement ceremony for the second batch of key projects, and the 100000-ton/year EVA project of Ningxia Coal Industry Company was officially started as one of the projects.

It is reported that the EVA project is planned to be put into production in December 2025 and is intended to adopt ExxonMobil's kettle process. The main raw materials are ethylene from the second phase of the olefin project and purchased vinyl acetate, and the auxiliary materials are mainly isobutylene, n-butane, isoparaffin solvent oil and isododecane solvent. Production of 9 grades of EVA products. on February 27, the methanol-to-olefin and downstream deep processing integration project of Guangxi Huayi Energy and Chemical Co., Ltd. was publicized before the environmental impact assessment was submitted for approval. It is reported that the project is located in Qinzhou Petrochemical Industrial Park, Guangxi, with a total investment of 11.8 billion yuan. It mainly builds 1 million tons/year methanol to olefin plant, 300000 tons/year vinyl acetate plant, 250000 tons/year tubular EVA plant, 100000 tons/year kettle EVA plant, etc. on September 21, 2022, the 2 #500000 t/a high-pressure polyethylene (EVA/LDPE) unit of Yulong Island Refining and Chemical Integration Project was officially started.

8. High-tech Petrochemical

on September 16, 2022, Tianli High-tech Petrochemical's 200000-ton/year EVA project was successfully started at one time, producing high-pressure polyethylene products, laying a solid foundation for the subsequent production of high quality EVA products.

It is reported that the EVA project belongs to PetroChina's first EVA device with a total investment of 2.462 billion yuan. The project will start construction on May 10, 2020 and achieve a high level of comprehensive delivery on June 30, 2022, with a construction period of 25 months. Basell's LUPOTECH T-tube reactor technology was used.9. Ju Zhengyuan (Jieyang)

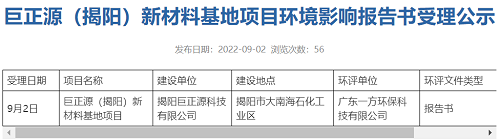

on June 28, Juzhengyuan (Jieyang) new material base project started. The total investment of the project is about 15.6 billion yuan. It mainly builds 600000 tons/year propane dehydrogenation unit, 300000 tons/year polypropylene unit, 160000 tons/year acrylic acid and 200000 tons/year butyl acrylate unit, 300000 tons/year butyl octanol unit, 150000 tons/year EVA unit, 600000 tons/year acetic acid and ester unit, 300000 tons/year vinyl acetate unit, etc.10. Zhongke Refining & Chemical

on August 29, 2022, the environmental impact report of the new No.2 EVA project of Zhongke Refining and Chemical Company will be publicized before approval. It is reported that the total investment of the project is 1.94 billion yuan, and a new 100000-ton/year EVA device is built, with a construction period of 24 months. The main products are EVA (ethylene-vinyl acetate copolymer) with different VA content. There are 12 product brands, all of which are sold as commodities. The main raw materials of ethylene and propylene are directly transported by the ethylene plant of Zhongke (Guangdong) Refining and Chemical Co., Ltd., and vinyl acetate is provided by Sinopec's unified layout. The device adopts the autoclave polymerization process technology of Lyondellbasell Company. Before February 28, 2023, Shanghai Petrochemical will hold Shanghai Petrochemical 100000 tons/year EVA project "construction in progress" assets transferred to China Science and Technology Refining, China Science and Technology Refining to Shanghai Petrochemical by batch payment method to pay the transfer price of 0.263 billion yuan (total amount including tax).11. Luoyang Petrochemical

on May 27, Sinopec Luoyang million tons of ethylene project and green petrochemical advanced materials industry base officially started. The project is located in the Advanced Manufacturing Development Zone of Mengjin District. Based on the raw materials provided by Luoyang Petrochemical Refinery, the ethylene project will build 13 petrochemical production units, including 150000 tons/year butadiene extraction unit, 250000 tons/year LDPE/EVA unit, 100000 tons/year EVA unit and 50000 tons/year SEBS unit, led by 1 million tons/year ethylene unit.12. Zhejiang Petrochemical

zhejiang Petrochemical's third 1.4 million-ton ethylene plant is also planned to be put into operation this year, which is an increase in process route optimization. High-performance resin project: The total investment of the project is expected to be 19.2 billion yuan. Using the chemicals produced in the first and second phases of Zhejiang Petrochemical Company as the main raw materials, a 300000-ton/year LDPE/EVA (tubular) device, a 100000-ton/year EVA (kettle type) device, a 400000-ton/year LDPE device, a 200000-ton/year DMC device, a 3 × 60000-ton/year PMMA device and a 1.2 million-ton/year ABS device are newly built. High-end new materials project: estimated total investment of 64.1 billion yuan. To tap the potential of the relevant devices of the 40 million-ton/year refining and chemical integration project, it is planned to build 4 million tons/year catalytic cracking unit, 350000 tons/year α-olefin unit, 2 × 200000 tons/year POE polyolefin elastomer unit, 80000 tons/year polybutene -1 unit, 1 million tons/year acetic acid unit, 2 × 300000 tons/year vinyl acetate unit, 300000 tons/year EVA/LDPE (tubular) unit, etc.13. Guangxi Petrochemical

on the afternoon of August 28, huanqiu engineering company held the kick-off meeting of Guangxi petrochemical refining and chemical integration transformation and upgrading project in the form of on-site and video. Guangxi Petrochemical Refining and Chemical Integration Transformation and Upgrading Project is located in Jinguo District, Petrochemical Park, Qinzhou Port Economic and Technological Development Zone, with a total investment of about 30.5 billion yuan. Including newly-built 1.2 million tons/year ethylene plant, 550000 tons/year pyrolysis gasoline hydrogenation plant/styrene extraction combined plant, 180000 tons/year butadiene extraction plant, 10/60000 tons/year MTBE/butene-1 plant, 350000 tons/year aromatics extraction plant, 400000 tons/year full density polyethylene plant (FDPE), 300000 tons/year high density polyethylene plant (HDPE), 300000 tons/year tubular ethylene-vinyl acetate plant (EVA), 100000 ton/year kettle type ethylene-vinyl acetate plant (H-EVA), 400000 ton/year polypropylene plant (PP), 50000 ton/year hexene -1 plant, 27/600000 ton/year propylene oxide/styrene plant (PO/SM), 300000 ton/year polystyrene plant (PS) and 12/80000 ton/year soluble styrene butadiene rubber integrated plant (SSBR/SBS). according to the record of investor relations activities disclosed by Lianhong Xinke on March 31, the 200000-ton/year EVA project under construction by the company adopts LyondellBasell high-pressure tubular process technology, mainly producing photovoltaic film products with high added value. After the project is put into production, the company will have both the LyondellBasell tube method and the ExxonMobil kettle method, which is conducive to improving the flexibility of production operations, flexible layout of product structure, and promoting new product development, when the company's EVA production capacity will exceed 350000 tons/year. jilin Petrochemical Transformation and Upgrading Project has a total investment of 33.9 billion yuan, with a total of 21 new refining and chemical units, 7 units renovated and 7 units shut down, including 150000 tons of ethylene. Newly built (renovated and expanded) 2.2 million tons/year wax oil hydrocracking, 1.2 million tons/year ethylene, 400000 tons/year high-density polyethylene unit, 400000 tons/year EVA unit and other advanced units will form a construction climax this year, and form production capacity in batches, and will be fully put into production in 2025. on August 3, the Ecological Environment Bureau of the Management Committee of Ningdong Energy and Chemical Base accepted the second set of environmental impact assessment documents for the 500000-ton/year coal-to-olefin project of Ningxia Baofeng Energy Group Co., Ltd.

At present, the company's main projects under construction are:(1) 200000 tons/year styrene project, which has been put into operation;(2) The third-phase olefin project is about to start, and the supporting 250000-ton EVA project is expected to be completed and put into operation by the end of October;(3) The 100000-ton/year needle coke project is expected to be put into operation by the end of this year;(4) The 100000-ton/year green hydrogen-to-green ammonia project and the 100000-ton/year vinyl acetate project are expected to be completed and put into operation in the first half of next year;(5) The progress of the 3 million-ton/year olefin project in Inner Mongolia is in line with the plan expectations. At present, the production capacity of Baofeng olefin plate is 600000 tons/year for Ningdong Phase I olefin and 600000 tons/year for Phase II olefin, totaling 1.2 million tons/year. The design capacity of Phase III is 1.15 million tons/year, including 400000 tons of polyethylene, 500000 tons of polypropylene and 250000 tons of EVA. It is currently preparing to start operation and 250000 tons of EVA is expected to be completed and put into operation by the end of October.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)