In recent years, the technology of China's chemical industry has made great progress, which makes the production mode of chemical products tend to be diversified, which leads to the differentiation of chemical market competitiveness. In this paper, the different production processes of propylene oxide are discussed in depth.

According to the survey, propylene oxide in a strict sense, there can be three production processes, namely, chlorohydrin, co-oxidation (Halcon) and hydrogen peroxide direct oxidation (HPPO). At present, the chlorohydrin method and HPPO method are the mainstream process of propylene oxide production.

The chlorohydrin method is a method for the production of propylene oxide by chlorohydrin, saponification, distillation and other processes using propylene and chlorine as raw materials. The process has a high yield of propylene oxide, but it also produces a large amount of waste water and waste gas, which has a great impact on the environment.

The co-oxidation process is a process that uses propylene, ethylbenzene and oxygen as raw materials to produce propylene oxide. First, ethylbenzene reacts with air to produce ethylbenzene peroxide, which then undergoes a cyclization reaction with propylene to produce propylene oxide and phenylethyl alcohol. This process has a more complex reaction process, and produces more by-products, so it also faces negative impact on the environment.

The HPPO method is a process in which methanol, propylene, and hydrogen peroxide are added to a reactor containing a zeolite titanium silicate catalyst (TS-1) at a mass ratio of 4.2:1.3:1 for reaction. The process can convert 98% of hydrogen peroxide, and the selectivity of propylene oxide can reach 95%, and a small amount of propylene that has not been completely reacted can be recycled to the reactor for reuse. Most importantly, the propylene oxide produced by this process is currently the only product allowed for export in China.

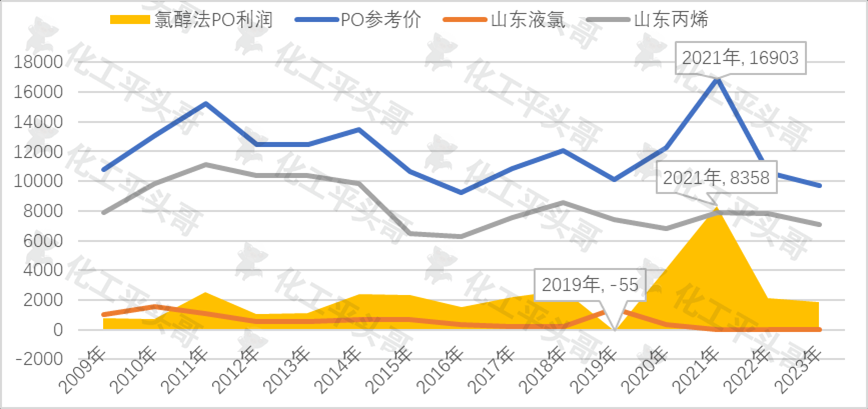

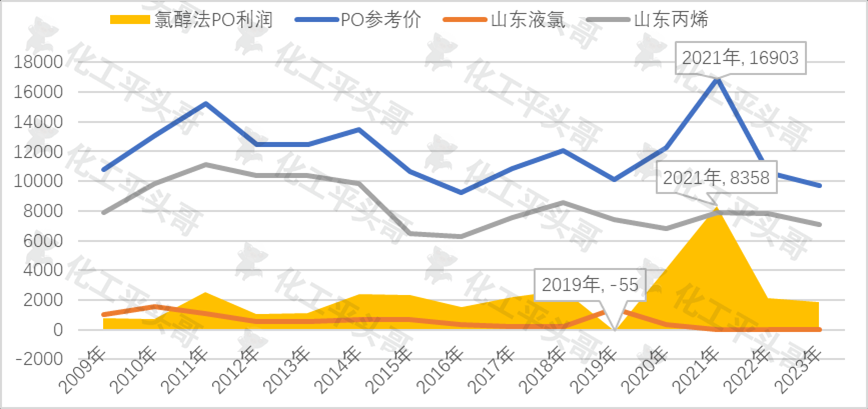

We measure from the price trend from 2009 to mid -2023, and look at the change pattern of the two processes, the chlorohydrin method and the HPPO method, over the past 14 years.

chlorohydrin method propylene oxide

1, chlorohydrin propylene oxide in most of the time in a profitable state. In the past 14 years, the production profit of chlorohydrin propylene oxide reached 8358 yuan/ton at its peak, which appeared in 2021, while in 2019 there was a small loss of 55 yuan/ton.

2, chlorohydrin method propylene oxide profit fluctuations and propylene oxide price fluctuations are consistent. When the price of propylene oxide rises, the profit from the production of propylene oxide by the chlorohydrin method rises accordingly. This consistency reflects that changes in market supply and demand and product value have a common impact on the prices of the two products. For example, in 2021, the epidemic led to a significant increase in the consumption of flexible foam polyethers, which in turn drove up the price of propylene oxide, ultimately creating a record high profit for the production of propylene oxide from the chlorohydrin method.

3. There is a long-term trend consistency in the price fluctuations of propylene and propylene oxide, but most of the time, there is a large gap between the two fluctuations. This shows that the price of propylene and propylene oxide are affected by different factors, and the price of propylene has a particularly significant effect on propylene oxide in chlorohydrin process. Since propylene is the main raw material for chlorohydrin propylene oxide, its price fluctuation will have a significant impact on the production cost of chlorohydrin propylene oxide.

In general, the production profit of chlorohydrin propylene oxide in China has been profitable for most of the past 14 years, and its profit fluctuations are consistent with the price fluctuations of propylene oxide, and the price of propylene is an important factor affecting the production profit of chlorohydrin propylene oxide.

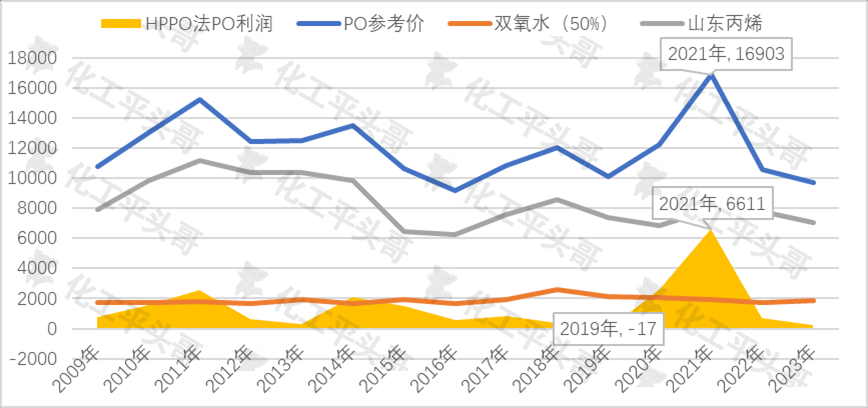

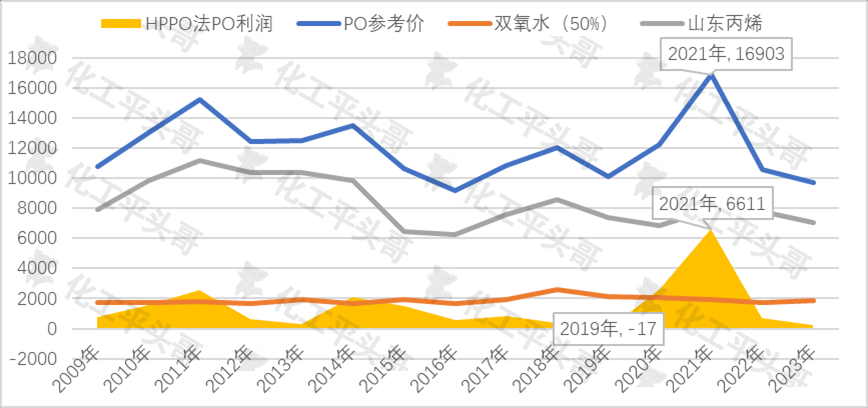

HPPO method propylene oxide

1. China's HPPO propylene oxide is profitable most of the time, but its profitability is generally lower than that of the chlorohydrin method. In a very small period of time, HPPO propylene oxide has suffered a loss, and in most of the time, its profit level has a significant gap with the chlorohydrin method.

2. Due to the sharp increase in the price of propylene oxide in 2021, the profit of HPPO propylene oxide in 2021 reached the highest value in history, and the maximum value reached 6611 yuan/ton. However, compared with the chlorohydrin method, there is still a gap of nearly 2000 yuan/ton. This shows that although the HPPO method has advantages in some aspects, the chlorohydrin method still has obvious advantages in the overall profit level.

3. In addition, by using 50% hydrogen peroxide price to measure the profit of HPPO method, it is found that there is no obvious correlation between the price of hydrogen peroxide and the price fluctuation of propylene and propylene oxide. This shows that the profit of propylene oxide in China's HPPO process is subject to the price of propylene and high concentration hydrogen peroxide. Since the price fluctuations of these raw materials and intermediate products are closely related to factors such as market supply and demand and production costs, they have an important impact on the production profit of HPPO propylene oxide.

The fluctuation of production profit of HPPO propylene oxide in China in the past 14 years has shown the characteristics of profit most of the time but low profit level. Although it has advantages in some aspects, it still needs to improve its profitability on the whole. At the same time, the profit of HPPO propylene oxide is greatly affected by the price fluctuation of raw materials and intermediate products, especially propylene and high concentration hydrogen peroxide. Therefore, manufacturers need to pay close attention to market dynamics and adjust production strategies reasonably to obtain the best profit level.

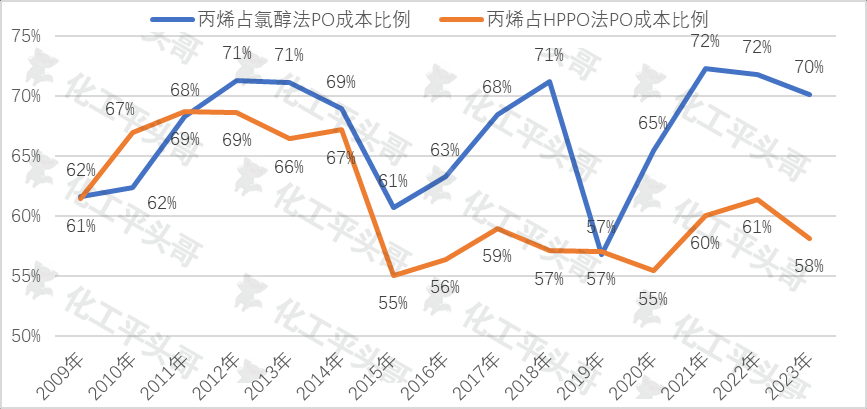

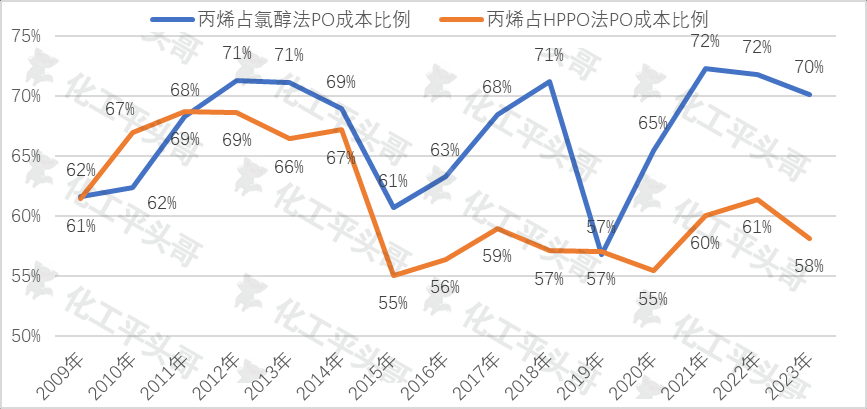

The influence of the main raw materials on the cost of the two production processes.

1. Although the profit fluctuations of chlorohydrin and HPPO propylene oxide show consistency, there are obvious differences in the impact of raw materials on their profits. This difference indicates that the two production processes have different cost management and profit control capabilities in response to fluctuations in raw material prices.

2, in the chlorohydrin method, the proportion of propylene to the cost of the average reached 67%, most of the time accounted for more than half, the highest reached 72%. This indicates that propylene has the largest cost impact weight in the chlorohydrin process. Therefore, the fluctuation of propylene price has a direct impact on the cost and profit of propylene oxide by chlorohydrin process. This observation is consistent with the long-term trend consistency of chlorohydrin propylene oxide production profits and propylene price fluctuations mentioned earlier.

In contrast, in the HPPO method, the average impact of propylene on its cost is 61%, the individual highest impact is 68%, and the lowest is 55%. This indicates that in the HPPO production process, the cost impact weight of propylene is large, but not as strong as the impact of the chlorohydrin method on its cost. This may be due to the fact that other raw materials such as hydrogen peroxide used in the HPPO process have a greater impact on costs, thereby reducing the impact of propylene price fluctuations on costs.

3. If the price of propylene fluctuates by 10%, the cost impact of the chlorohydrin method will exceed that of the HPPO method. This means that the cost of the chlorohydrin method is more affected in the face of propylene price fluctuations, and the HPPO method has better cost management and profit control capabilities. This observation once again highlights how different production processes respond to fluctuations in raw material prices.

There is consistency in the profit fluctuation of China's chlorohydrin method and HPPO propylene oxide method, but the impact of raw materials on their profits is different. In response to fluctuations in raw material prices, the two production processes show different cost management and profit control capabilities. Among them, the chlorohydrin method is more sensitive to propylene price fluctuations, while the HPPO method has better anti-risk ability. These rules have important guiding significance for enterprises to choose production process and formulate production strategy.

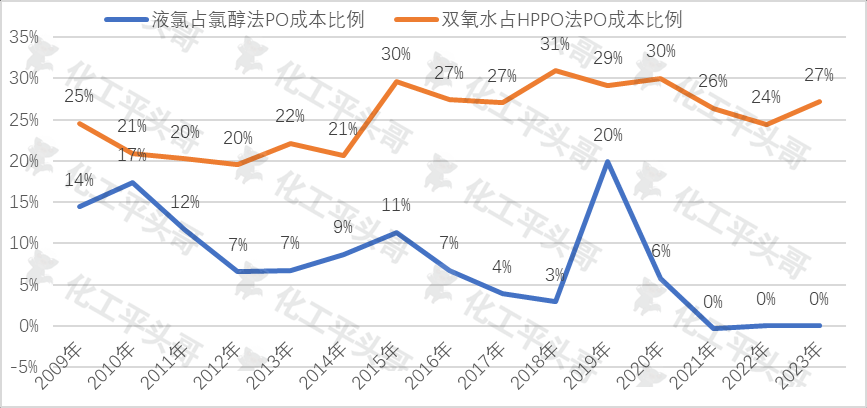

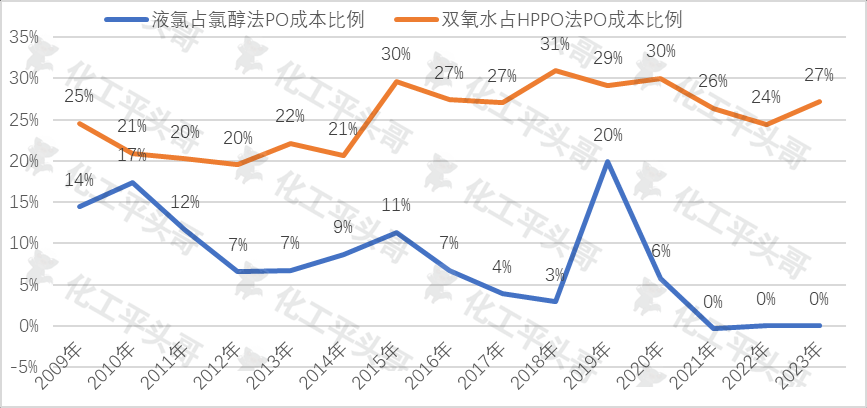

The influence of auxiliary materials on the cost of the two production processes.

1, liquid chlorine on the chlorohydrin method propylene oxide cost ratio impact in the past 14 years, the average value of only 8%, even can be considered almost no direct cost impact. This observation shows that liquid chlorine plays a relatively minor role in the chlorohydrin production process, and its price fluctuations have a small impact on the cost of chlorohydrin propylene oxide.

2, high concentration of hydrogen peroxide on the cost of HPPO propylene oxide is significantly higher than the cost of chlorine on the chlorohydrin method. Hydrogen peroxide is a key oxidant in the HPPO production process, and its price fluctuation has a direct impact on the cost of propylene oxide in the HPPO process, second only to propylene. This observation highlights the importance of hydrogen peroxide in the HPPO process.

3, if the enterprise's own by-product chlorine, its chlorine on the chlorohydrin method of propylene oxide cost impact can be ignored. This may be because the amount of by-product chlorine gas is usually small, which has a relatively limited impact on the cost of propylene oxide in the chlorohydrin process.

4. If 75% hydrogen peroxide is used, the cost impact of hydrogen peroxide on HPPO propylene oxide will exceed 30%, and the cost impact will continue to increase rapidly. This observation shows that the propylene oxide of the HPPO process is not only affected by large fluctuations in the raw material propylene, but also by large fluctuations in the price of hydrogen peroxide. As the concentration of hydrogen peroxide used in the HPPO production process is increased to 75%, the amount and cost of hydrogen peroxide will increase accordingly, the market will have more influencing factors, the volatility of its profits will be greater, and the impact on its market price will be greater.

For the production process of chlorohydrin and HPPO propylene oxide, there are significant differences in the cost impact of the raw materials of the auxiliary materials. The effect of liquid chlorine on the cost of propylene oxide by chlorohydrin process is small, while the effect of hydrogen peroxide on the cost of propylene oxide by HPPO process is more significant. At the same time, if the company's own by-product chlorine or the use of different concentrations of hydrogen peroxide, the cost impact will be different. These laws have important guiding significance for enterprises to choose production processes, formulate production strategies and carry out cost control.

According to the current data and trends, the future propylene oxide projects under construction will exceed the current scale, and most of the new projects will use HPPO method and ethylbenzene co-oxidation method. This phenomenon will lead to an increase in the demand for raw materials such as propylene and hydrogen peroxide, which will have a greater impact on the cost of propylene oxide and the overall cost of the industry.

From the cost point of view, enterprises with the development of industrial chain integration mode can better control the influence weight of raw materials, so as to reduce costs and improve market competitiveness. As most of the new propylene oxide projects in the future use the HPPO method, the demand for hydrogen peroxide will also increase, which will increase the weight of the impact of hydrogen peroxide price fluctuations on the cost of propylene oxide.

In addition, the impact of propylene price fluctuations on the cost of propylene oxide will also increase as the use of ethylbenzene co-oxidation in future new propylene oxide projects will also increase the demand for propylene. These factors will bring more challenges and opportunities to the propylene oxide industry.

In general, in the future, the development of the propylene oxide industry will be affected by the projects under construction and raw materials. For companies that adopt the HPPO method and the ethylbenzene co-oxidation method, they need to pay more attention to cost control and the integrated development of the industrial chain. For raw material suppliers, it is necessary to strengthen the stability of raw material supply and control costs to improve market competitiveness.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)