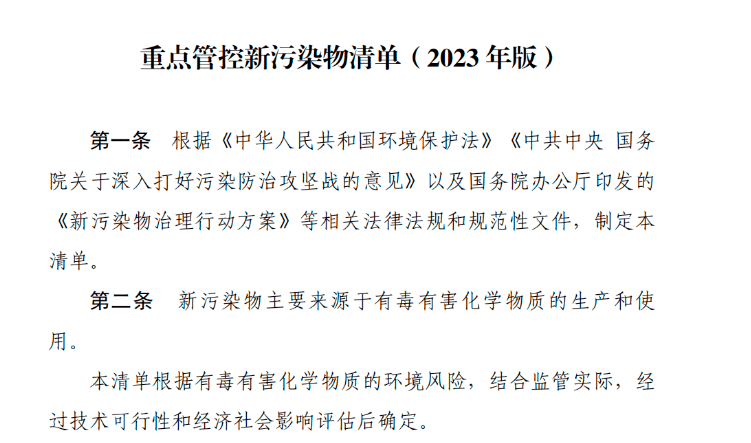

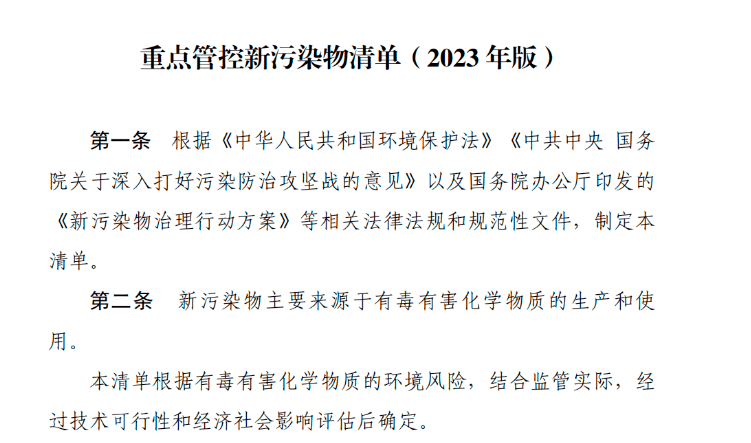

, according to the Ministry of Ecological Environment January 13 news, recently, the Ministry of Ecological Environment in conjunction with relevant departments issued the "Key Control of New Pollutants List (2023 Edition)" (Ministry of Ecological Environment Order No. 28, hereinafter referred to as the "List"), Will be implemented on March 1, 2023.

The List of mainly includes four categories of 14 new pollutants:

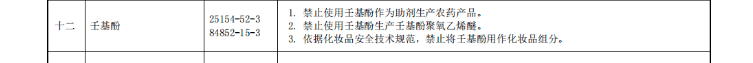

No. 12 is a recent environmental endocrine disruptor nonylphenol that is highly concerned by the society. In China, nonylphenol is mainly used in the production of surfactants-nonylphenol ethoxylates, a small part of the pesticide additives. The main environmental risks focus on the point source emissions of production and use enterprises, as well as the environmental risks caused by the environmental emissions of related products in the use process. Combined with China's current management regulations, three control measures are taken: first, it is forbidden to use nonylphenol as an auxiliary agent to produce pesticide products; second, it is forbidden to use nonylphenol to produce nonylphenol ethoxylates; third, it is forbidden to use nonylphenol as a cosmetic component.

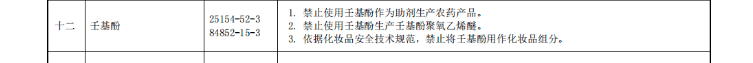

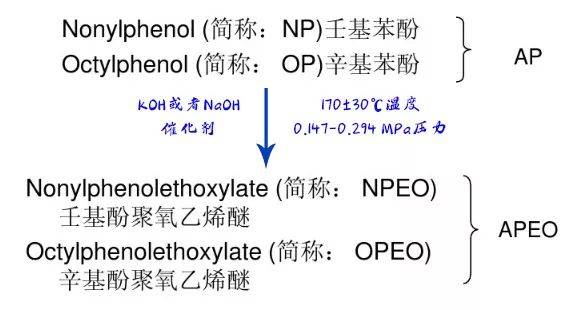

1. What is APEO alkylphenol and alkylphenol ethoxylates are the abbreviation of alkylphenol ethoxylates, including alkylphenol (AP) and alkylphenol ethoxylates (APEO), which are the main representatives of the widely used nonionic surfactants. It has good wetting, penetration, emulsification, dispersion, solubilization and washing effect, and is widely used in detergents, personal care products, textile, paper, petroleum, metallurgy, pesticides, pharmaceuticals, printing, synthetic rubber, synthetic resins, plastics and even food The processing and manufacturing of industry products, the most important use is washing products and textile auxiliaries.

2. Alkylphenol ethoxylates (APEO) is a kind of polyoxyethylene nonionic surfactant.

APEO is prepared by polymerizing alkylphenol (AP), mainly nonylphenol (NP) and octylphenol (OP), according to a certain proportion, with KOH or NaOH as catalyst, at 170±30 ℃, 0.147-0.294 MPa pressure, to generate a series of mixtures with different polymerization degrees. APEO after polymerization mainly includes:

① Nonylphenol ethoxylates (NPEO): 80 ~ 85%;

② Octyl phenol polyoxyethylene ether (OPEO): 15% or more; ③ dodecylphenol ethoxylates (DPEO): 1%;

④ Dinonylphenol ethoxylates (DNPEO): 1%.

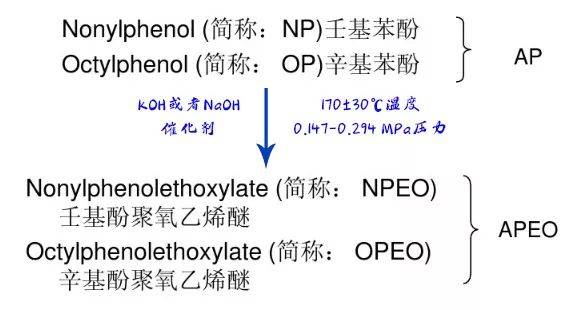

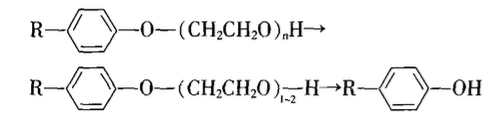

, APEO has an amphiphilic structure, the hydrophobic group is a benzene ring and its attached carbon chain, and the hydrophilic group is an epoxy vinyl group.

3. Why disable APEO APEO on the ecological impact of the can be summarized into the following four aspects: toxicity, biodegradability, environmental hormones, in the production process of harmful by-products.

alkylphenol AP is a mimic estrogen and is also known as an endocrine disruptor. Due to the "toxicity, persistence and bioaccumulation" of nonylphenol (NP), the European Union restricts the use of nonylphenol.

alkylphenol polyoxyethylene ether itself does not have carcinogenicity and variability, but when added with ethylene oxide, due to excessive accumulation of unreacted ethylene oxide, oligoethylene and dipolyoxyethylene ring structure is 1,4-dioxane. These two compounds have been identified as carcinogens and require that the unreacted oxyethylene content be limited to 1 mg/kg.

APEO biodegrades slowly. After degradation, APEO and alkyl phenol (AP) with less ethoxy group (EO) are produced, and nonylphenol (NP) and octylphenol (OP) are produced. NP, OP, NPEO and OPEO are all environmental hormone chemicals, which have similar effects of estrogen after invading the human body, the so-called "female effect" and reproductive aberration, and have become the natural enemies of all living things, including human beings.

4.APEO Disablement History at home and abroad for nonylphenol and nonylphenol polyether use and limited to give great attention and attention.

Abroad

Since 1998, Germany has banned the use of APEO in detergents. Since January 2005, the use of NPEO in formulations at concentrations higher than 0.1 percent has been prohibited in EU regulations. These compounds tend to end up in wastewater, causing environmental problems.

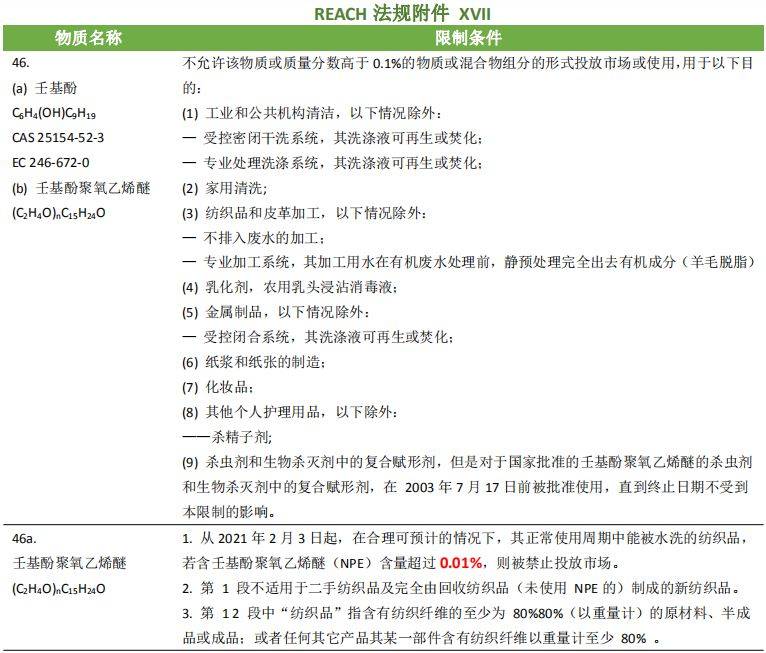

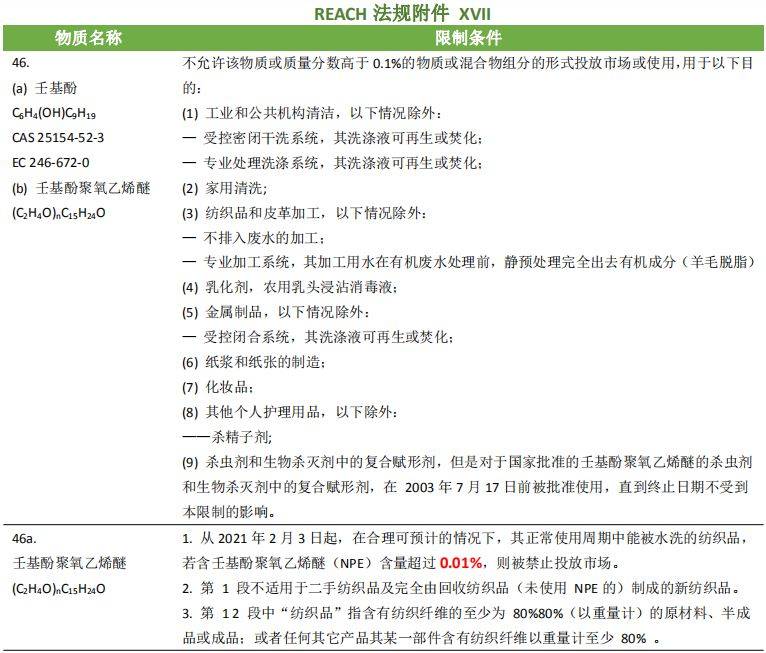

in July 2012, Germany had proposed to include nonylphenol in the REACH regulation of substances of high concern list, the same year in December, in the eighth batch of substances of high concern list, appeared nonylphenol, and defined as may be serious harm to the environment, restrictions are as follows:

When the concentration of nonylphenol and nonylphenol ethoxylates is greater than or equal to 0.1%, it shall not be placed on the market or used as an ingredient in substances or mixtures for the following purposes: industrial and institutional cleaning agents, household cleaning, textile and leather products Treatment, agricultural emulsifiers, metal processing, pulp and paper formulations, cosmetics, other personal care products, pesticides or antibiotic formulations.in 2016, the EU amended the REACH regulation, from 2021 onwards, textile products banned the use of nonylphenol ethoxylates.

Domestic The Ministry of Industry and Information Technology on the issuance of the textile industry development plan (2016-2020) notice to speed up the green development process mentioned in Article 4, strengthen the development of toxic and harmful chemicals alternative technology, establish a textile chemical risk management and control mechanism, and gradually restrict nonylphenol, nonylphenol polyoxyethylene ether and other toxic and harmful substances in textiles, encourage the establishment of enterprise environment, chemical use information disclosure mechanism.

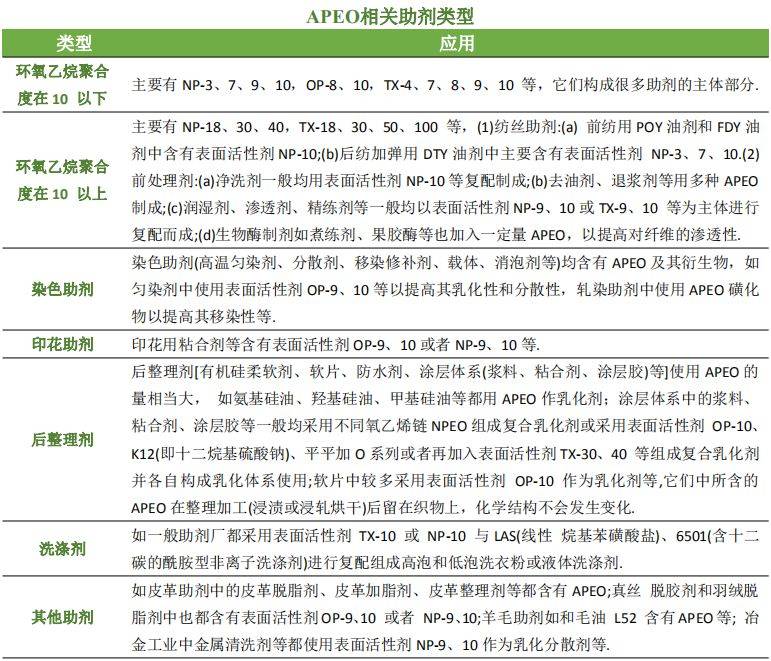

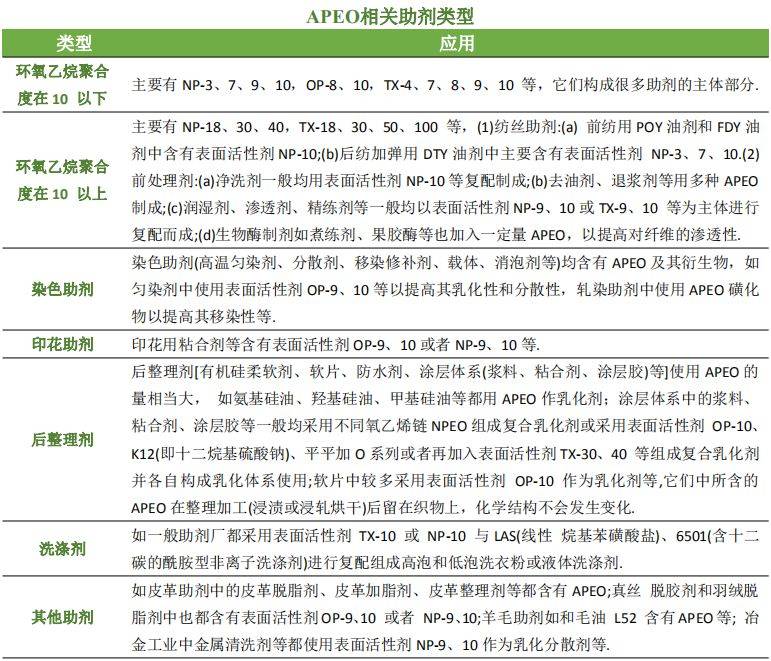

5. Which printing and dyeing auxiliaries will contain APEO APEO in the textile processing process is almost ubiquitous, textile processing commonly used scouring agent, wetting agent, penetrating agent, enzyme preparation, printing slurry, adhesive, coating agent, leveling agent, waterproof agent, repair agent, all kinds of emulsion, dispersant, etc. are likely to find the figure of APEO. In the world's total surfactant consumption of about 7.5% share.

the APEO series of products in the trade name is TX-10, OP-10, NP-7,9,10 is a lot of additives of the main part, in addition to TX-18, TX-30,40 is some additives of the important components.

How to avoid APEO 1, do not use APEO raw materials is the simplest method , from the root of the ban on the use of APEO, auxiliary manufacturers best understand whether the product contains banned chemicals, auxiliary factory product detection is also easier than on the fabric, in the fabric to detect very small amount often need high precision, more expensive instruments and equipment; and in the auxiliary detection is often more simple and easy.

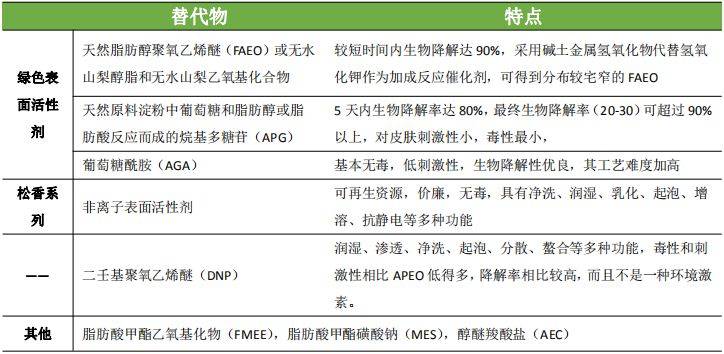

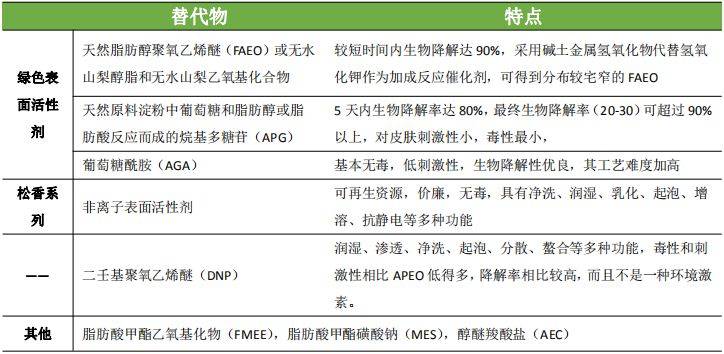

use "fatty alcohol polyoxyethylene ether" or "branched fatty alcohol polyoxyethylene ether" instead of APEO. For example, the commercial brands are AEO series (C12-C16 fatty alcohol polyoxyethylene ether), Pingjia 0(C18 fatty alcohol polyoxyethylene ether) or XL-50 (heterogeneous C10 alcohol polyoxyethylene ether, T07 (heterogeneous C13 alcohol polyoxyethylene ether), etc. These products also have excellent properties of penetration, emulsification and solubilization. If the scouring agent and penetrating agent need to improve the alkali resistance, surfactants with high alkali resistance such as AES (dodecyl polyoxyethylene ether sulfate), SAS (sodium secondary alkyl sulfonate), AOS(α-olefin sulfonate), alkyl polyglycoside (APG) can be compounded in the auxiliary agent. These surfactants have good biodegradability, do not contain carcinogenic aromatic amines, do not contain heavy metal ions, and do not cause harm to human health.

Environmentally friendly surfactant

2, APEO removal printing and dyeing manufacturers must purposefully choose ecological and environmental protection chemicals, and strictly control the additives from pre-treatment to post-finishing. If you accidentally use the additives containing APEO, don't be too pessimistic, you can use the relevant additives to clean off.

Source: of Pesticide Formulation Blog * Disclaimer: The content is from the Internet, WeChat public number and other public channels, we maintain a neutral attitude towards the views in the article. This article is for reference only, exchange. The copyright of the reproduced manuscript belongs to the original author and institution. If there is any infringement, please contact the customer service of Huayi World to delete it. Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)