Recently, the Ministry of Industry and Information Technology and other six departments jointly issued "Guiding Opinions on" the 14th Five-Year Plan "promoting high-quality development of petrochemical and chemical industry" (Ministry of Industry and Information Technology (former [2022] No. 34) released. According to the guidance, by 2025, the production concentration of bulk chemical products will be further improved, and the utilization rate of production capacity will reach more than 80%; The level of ethylene equivalent guarantee will be greatly improved, and the level of new chemical materials guarantee will reach more than 75%. Guide the lightening of olefin raw materials, accelerate the development and application of technologies for direct cracking of crude oil to produce ethylene and one-step synthesis of synthetic gas to produce olefin, enhance the supply capacity of high-end polymers, accelerate the development of high-end polyolefin, and create an innovation center for high-end polyolefin.

Thus, the development of the whole industrial chain of high-end Polyolefin will accelerate during the "14th Five-Year Plan" period.

From Sinopec, PetroChina, Wanhua Chemical, to Zhejiang Petrochemical, Hengli Petrochemical, Shenghong refining, satellite chemistry, Baofeng Energy and other private enterprises in the whole industry chain layout, we are all focusing on the development of large ethylene + high-end polyolefin or large ethylene + new chemical materials. Accelerate the development and application of direct cracking of crude oil to Ethylene Technology

through technological changes, the proportion of crude oil chemicals has increased from 10% to 76%, which is expected to reach 80%. The chemical raw materials for maximizing crude oil production are generally divided into two routes: aromatic hydrocarbon and low carbon olefin. Catalytic cracking is the core technology for the process that mainly produces low-carbon alkenes.

There are three main directions to maximize the production of low-carbon olefin in crude oil, namely, the largest amount of ethylene, the largest amount of propylene, and the largest amount of propylene and ethylene. Catalytic cracking is the core technology for maximizing the production of low-carbon olefin in crude oil. Catalytic cracking has a wide range of sources of raw materials and can be various heavy raw materials of conventional catalytic cracking (FCC), including vacuum wax oil (VGO), heavy distillates such as asphalt oil (DAO), coking wax oil (CGO), hydrotreating vacuum wax oil (HT-VGO), hydrocracking tail oil, atmospheric residue (AR) and mixed vacuum residue (VTB) the vacuum wax oil mixture (Blending of VGO and VTB) can also be naphtha fraction, C4/C5 light hydrocarbon, etc., which is less harsh than steam cracking operation conditions, and the product distribution can be flexibly adjusted.

The biggest feature of crude oil direct steam cracking route is that refining units such as atmospheric and vacuum distillation are omitted, which greatly shortens the process. The most representative technologies are Exxon Mobil technology and Saudi Aramco/Saudi Basic Industries technology. It is worth noting that the raw materials used by the two technologies are very light crude oil. The API degree of crude oil used by Exxon Mobil is about 42.7, and that of Saudi Aramco is about 34, this route has certain requirements on the quality of crude oil and is limited by the supply of raw materials.

ExxonMobil crude oil direct steam cracking technology

exxonMobil adopted the process of direct production of ethylene from crude oil. In 2014, it built the world's first commercial unit in Jurong Island, Singapore, with an ethylene capacity of 1 million tons/year, the main process improvement is to add a flash tank between the convection section and the radiation section of the cracking furnace. After the crude oil (light crude oil) is preheated in the convection section, it enters the flash tank together with the diluted steam, and the gas-liquid components are separated, among them, the gaseous component (mass fraction 76%) enters the radiation section for cracking, and the liquid component (mass fraction 24%) is sent to the adjacent refinery or directly sold. The overall investment is slightly higher than that of steam cracking unit, but the price trend of crude oil and naphtha is positively correlated, and the price difference between the two is relatively stable. Under the oil price of US $50/barrel (US $365/ton), the average price of naphtha for steam cracking fluctuates around US $480/ton, and the average price difference between the two is about US $100/ton. The price difference of raw materials makes direct production of olefin from crude oil have certain cost advantages.

ExxonMobil has integrated more than 90% of its chemical production capacity with its refineries or gas-processing plant, and has 17 integrated bases (including Guangzhou Huizhou project) around the world. The competitiveness of its chemical products is mainly reflected in the differentiation and high-end of polymers, including metallocene polyethylene, Metallocene polypropylene, ethylene octene copolymer elastomer (POE) and thermoplastic dynamic vulcanized elastomer.™(TPV) and butyl rubber and EPDM Vistalon™Other advantages elastomer products. In the future, downstream investment will also focus on high-end polyolefin and elastomer projects.

Direct steam cracking technology of Saudi Aramco crude oil

the process of Saudi Aramco/Saudi Basic Industry Company is that crude oil (Saudi light oil) directly enters the hydrocracking unit, desulfurizes and converts high boiling point components into low boiling point components; After separation, light components enter the steam cracking unit, and heavy constituent enter the high-severity catalytic cracking unit independently developed by Saudi Aramco to maximize olefin production. The chemical yield of this process is greatly increased, and the proportion of crude oil chemicals reaches 45%. Compared with naphtha steam cracking ethylene production plant, the gross profit per ton of oil is increased by 100~200 USD/ton, but the investment is much higher, therefore, generally speaking, the production cost of olefin is not much different from that of naphtha steam cracking.

In order to achieve higher chemical conversion rate and promote the commercialization of the technology, Saudi Aramco signed a joint development agreement with CB & I and Chevron ruhms in January 2018, combining CB & I ethylene cracking technology, CLG hydrotreating technology and Saudi Aramco crude oil Chemical Technology (TC2CTM), the proportion of crude oil chemical can reach 70% ~ 80%.

In June 2018, Saudi Aramco announced that it would adopt the methane oxidative coupling to olefin (OCM) technology of American company Siluria in its crude oil direct chemical (COTC) project, the application of this technology will increase ethylene production by more than 10%. At present, the COTC project of Saudi Aramco/Saudi Basic Industry Company is under construction.

Sinopec light crude oil cracking to Ethylene Technology

the key research project of Sinopec "technology development and industrial application of light crude oil cracking to ethylene" has been successfully tested in Tianjin petrochemical industry, which can directly convert crude oil into ethylene, chemicals such as propylene (I .e. "oil conversion"), realizing the first domestic industrial application of crude oil steam cracking technology. According to calculation, every 1 million tons of crude oil processed by this technology can produce nearly 500,000 tons of chemicals, among which the high-value products such as ethylene, propylene, light aromatic hydrocarbon and hydrogen are nearly 400,000 tons, and the overall technology reaches the international advanced level, the economic value is huge.

Sinopec has the world's advanced catalytic cracking technology of crude oil, and now it has added the technology of direct ethylene production by steam cracking of crude oil. The combination of the two technologies is expected to increase the total amount of chemicals produced by crude oil to more than 70%, it will become an economically feasible technical route for "oil conversion" in the future. Generally, the raw materials needed for ethylene and propylene production need to go through the crude oil refining process of the refinery, with a long production process, and only about 30% of the crude oil is used to produce chemical raw materials. This crude oil steam cracking technology is one of the routes of "oil conversion". It "skips" The traditional crude oil refining process and directly converts crude oil into chemicals such as ethylene and propylene, it is equivalent to that wheat can be directly made into bread, eliminating the link of grinding into flour. This will greatly shorten the production process, reduce production costs, and greatly reduce energy consumption and carbon emissions.

Direct ethylene production technology from Sinopec crude oil catalytic cracking

the oil catalytic cracking technology independently developed by the petrochemical research institute affiliated to Sinopec successfully conducted industrial tests in Yangzhou Petrochemical Company, directly converting crude oil into light olefin, aromatic hydrocarbon and other chemicals.

This is the first industrial application of crude oil catalytic cracking technology in the world, marking a breakthrough in China's crude oil direct chemical production technology and becoming the world leader in crude oil catalytic cracking technology route.

The figure shows the industrial test device of crude oil catalytic cracking technology of Shiyuan Academy of Sciences.

Catalytic cracking technology of crude oil is one of the technical routes for direct chemical production of crude oil, which directly converts crude oil into light alkenes and aromatic hydrocarbons.

The test results show that the total yield of low-carbon olefin and light aromatic hydrocarbon increases twice, reaching more than 50%, that is, using this technology to process 1 million tons of crude oil can produce about 500,000 tons of high-value chemicals, which is of great economic value.

The picture shows that the research and development team of crude oil catalytic cracking technology of Shi Academy of Sciences is on the industrial test site.

the scale of newly-built ethylene in China is concentrated between 100-1.5 million tons/year. Zhejiang Petrochemical, Dushanzi Petrochemical, Lanzhou Petrochemical and other enterprises lead the development of domestic large ethylene scale. Private refining follows the principle of "reducing oil and increasing", and the ethylene yield increases to about 50%.

Zhejiang Petrochemical still has 2.5 phase planning, Gulei Petrochemical (Phase II), Zhongke refining (Phase II), Zhongsha Gulei, ExxonMobil (Huizhou), BASF (Zhanjiang), Guangdong petrochemical, Hainan refining, luoyang petrochemical, Yueyang petrochemical, Guangxi petrochemical and so on all have big ethylene integration project construction.

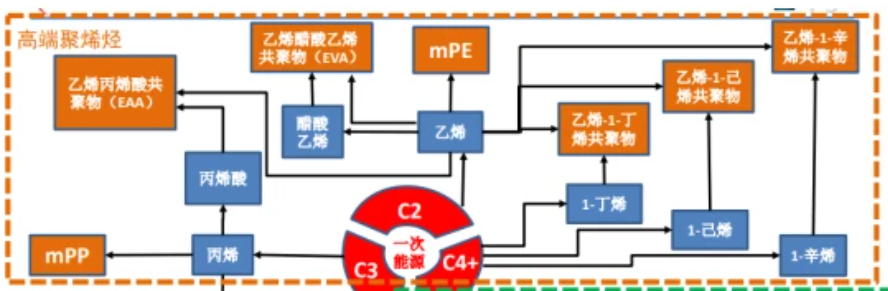

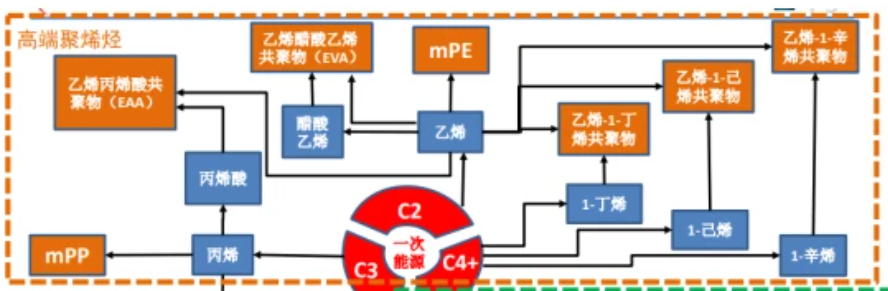

Development of high-end Polyolefin

from the global production layout, high-end polyolefin production is mainly concentrated in Western Europe, Southeast Asia and North America, and the Middle East is dominated by bulk general materials, of which Japan is the main producer of high-end polyolefin in Southeast Asia. Related enterprises include ExxonMobil, Dow chemistry, BASF, LyondellBasell, Total, Mitsui chemistry, Sumitomo chemistry, Asahi Huacheng, etc.

Domestic polyolefin production enterprises represented by Sinopec, PetroChina, etc. are accelerating to break through the technical barriers of high-end polyolefin. Including R & D and production of a-olefin, metallocene catalyst, non-metallocene catalyst, etc.

High-end polyolefin products are widely used in high-end pipes, auto parts, medical equipment, industrial pipelines, high-end electronics and electricity, etc.

Development of new chemical materials

the development of new chemical materials industry cannot be separated from the leading role of the market. The development of new energy vehicles, biology, high-end equipment, new energy, environmental protection and energy saving, rail transit and other industries urgently needs the support of many kinds of new functional chemical materials. Based on the previous analysis of industry development characteristics, at present, the self-sufficiency rate of some high-performance new chemical materials in China still cannot fully meet the market demand, and there is still much room for development in the industry.

Source: polyolefin people* Disclaimer: the content contained is from public channels such as the Internet and WeChat public accounts. We maintain a neutral attitude towards the views in this article. This article is for reference and communication only. The copyright of the reprinted manuscript belongs to the original author and organization. If there is any infringement, please contact Huanyi world customer service to delete it. Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)