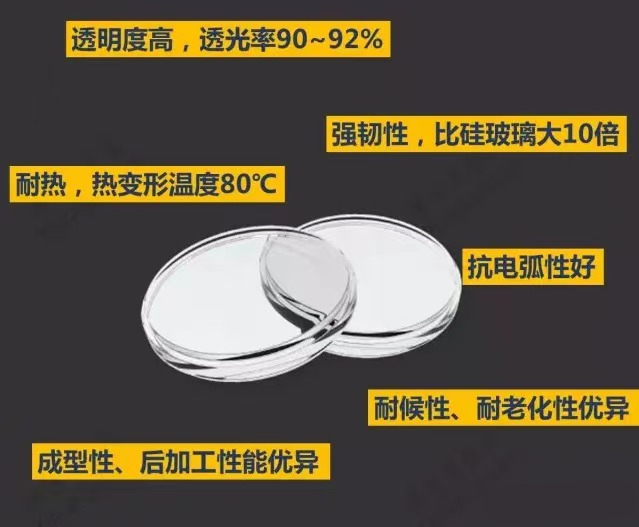

polymethyl methacrylate (PMMA) is commonly known as plexiglass, acrylic, etc. It is an amorphous plastic copolymerized by MMA monomer and a small amount of acrylate. It has good transparency and optical properties., Weather resistance, drug resistance, impact resistance and aesthetics are high-grade materials known as the "plastic queen". The products include molded plastics, extruded plates and cast plates.

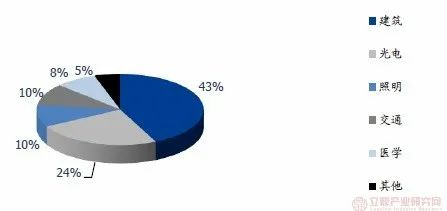

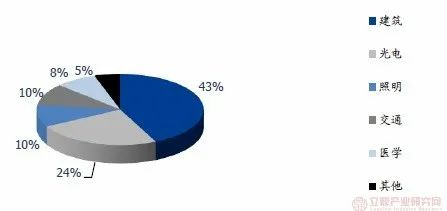

With excellent optical performance, PMMA is widely used downstream. The main application fields of low-end PMMA are advertising light boxes, signs, lamps, bathtubs, meters, daily necessities, furniture, etc, high-end PMMA is mainly used in liquid crystal displays, radiation PMMA, optical fibers, solar photovoltaic cells, automobile lampshades, bulletproof glass, aircraft cockpit glass, medical polymer materials, military optical equipment, high-speed rail windows, police shields, high-end diving goggles and other fields. It has been included in the "12th Five-Year Plan" for the development of high-end petrochemical and chemical products in the "12th Five-Year Plan" of my country's "Petrochemical and Chemical Industry. Especially in recent years, the rapid development of liquid crystal display field has driven the demand for optical PMMA materials to grow rapidly.  From the perspective of product performance and application, PMMA is divided into general-purpose, heat-resistant, optical and impact-resistant products. With the rapid growth of the liquid crystal display market, the use of PMMA, which has driven high-end optics, has increased significantly. Application areas include liquid crystal displays, LED flat panel lights, optical fibers, etc., and the continuous development of modification and composite material technology has also made PMMA applications in mobile phone backplanes, automotive lightweight and other fields have been continuously developed. It is expected that my country's PMMA demand will continue to maintain a relatively high growth in the future.

From the perspective of product performance and application, PMMA is divided into general-purpose, heat-resistant, optical and impact-resistant products. With the rapid growth of the liquid crystal display market, the use of PMMA, which has driven high-end optics, has increased significantly. Application areas include liquid crystal displays, LED flat panel lights, optical fibers, etc., and the continuous development of modification and composite material technology has also made PMMA applications in mobile phone backplanes, automotive lightweight and other fields have been continuously developed. It is expected that my country's PMMA demand will continue to maintain a relatively high growth in the future. Main application areas of PMMA

LCD light guide plate is one of the fastest growing fields in PMMA downstream applications. The backlight module in the liquid crystal panel is mainly composed of a light source, a light guide plate and an optical film. The light guide plate is mainly used in the LCD backlight module to uniformly guide the light emitted by the light source to the display surface, and the main material is PMMA.

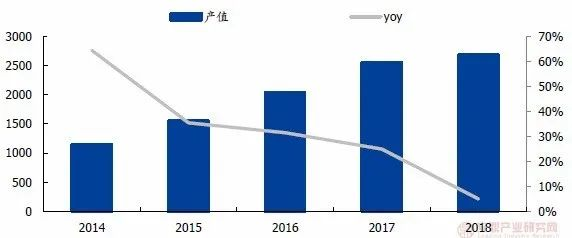

The global flat panel display industry is concentrated in South Korea, Taiwan, Japan and mainland China. Driven by large-screen mobile phones, TV sizes, car displays and public displays, the global new display industry continues to grow. In recent years, driven by the rapid growth of demand in the downstream market and the support of relevant national industrial policies, domestic display panels and materials have ushered in rapid development, represented by BOE, Huaxing Optoelectronics, Tianma, Longteng Optoelectronics, CLP Panda, etc. The rise of a group of panel production companies has led to the rapid development of the mainland's flat panel display industry chain. The panel industry has a clear trend of continuous transfer to the country. According to Qunzhi Consulting statistics, it is estimated that domestic panel factories will account for more than 40% of the global LCD TV panel market by 2019 and are expected to exceed 50% by 2022, which will drive the demand for light guide plates to continue to grow. of In the field of lighting, LED lighting, as a new type of green light source product, has the characteristics of energy saving, environmental protection, long life, small volume, etc. compared with traditional light sources, and is widely used in various fields such as indication, display, decoration, backlight, general lighting and urban night scene. At present, LED has become an ecological light source with high cost performance, and has entered the lighting alternative market in an all-round way. Under the general trend of eliminating incandescent lamps and limiting the use of fluorescent lamps (containing mercury), the global semiconductor lighting market has grown rapidly, becoming a leap in the history of human lighting and is recognized as the most promising electric light source in the 21st century. Under the trend of accelerating the elimination of incandescent lamps in the world, China's LED industry has grown rapidly in recent years, benefiting from the rapid increase in LED penetration rate. In recent years, the proportion of general lighting in the downstream application market has continued to increase. In 2014-2018, China's LED general lighting output value continued to increase, reaching 267.9 billion yuan in 2018, up 5.0% year on year. China's general LED lighting industry scale (100 million yuan) of LED flat panel lamp is a kind of LED lighting product widely used in indoor (residential, office building, commercial shops) and outdoor (road, landscape) lighting. It mainly uses light guide plate to convert LED point light source or line light source into surface light source, so that light can be evenly emitted from the front of flat panel lamp, effectively expanding the coverage area of light source. The high-end brands of LED flat panel lights (mainly used indoors) mainly use PMMA light guide plates as raw materials, and their light transmittance is higher. Compared with traditional light sources, LED light sources have many advantages such as energy saving, environmental protection, long service life, stable light source, etc. Plastic optical fiber made of

PMMA optical fiber materials PMMA materials is an excellent short-distance data transmission medium, which is considered to be the best solution for the "last kilometer" of FTTH, and conforms to the national industrial development direction of "light advance and copper retreat, low carbon, energy saving and environmental protection. Worldwide, the main production of plastic optical fiber companies are Japan's Mitsubishi, Asahi Kasei, Toray and other companies, as well as the United States's Boston company. After years of hard work, Chinese scientists have mastered a complete set of technologies for purifying raw materials and directly drawing plastic optical fibers through bulk polymerization. The Institute of Physics and Chemistry of the Chinese Academy of Sciences has successfully developed a full-automatic assembly line for PMMA plastic optical fibers with a daily output of 100,000 meters. For several months, PMMA optical fibers with a light attenuation of 170-200db/km have been stably produced, and millions of meters of low-loss plastic optical fibers have been produced. At the same time, in addition to the field of optical communication, plastic optical fiber is also used in landscape lighting. The landscape project at the opening and closing ceremonies of the 2012 London Olympics uses plastic optical fiber supplied by Shenzhen Huaying Century Optoelectronic Technology Co., Ltd. At present, the use of plastic optical fiber for landscape lighting is still in its infancy in China, but the development prospect is worth looking forward to. the

of

composite plate replacing metal for mobile phone back cover

mobile phone back cover is a new application field of PMMA. The 5G era is gradually coming. In order to meet the development direction of thinner and more portable and the higher requirements of 5G communication for signal transmission, composite plate (PC + PMMA) has become a new scheme to replace the traditional metal back cover with ceramics and glass. PC/PMMA composite board is prepared by co-extrusion of PC and PMMA. PMMA is generally used for external use due to its good hardness and wear resistance, while PC has good toughness, so it is used as inner layer. The PC/PMMA composite board has the advantages of both PC and PMMA, which can not only meet the requirements of rigidity and decoration, but also meet the needs of wireless charging without shielding, and has lower cost than 3D glass and ceramic. Composite sheet and 3D glass performance comparison of automotive lightweight materials new energy vehicle subsidies are added to the ground, and increasing the cruising range is an important challenge currently facing car companies, and automotive lightweight technology is an effective way to improve cruising range One of the methods. For every 10% reduction in automobile weight, its energy consumption can be reduced by 6% ~ 8%, while exhaust emissions can be reduced by about 4%. Therefore, automobile lightweight technology is an important new technology to achieve automobile energy saving, environmental protection, safety and other development goals. The key to

automobile lightweight is to use lightweight, safe and high-performance materials. Plastics and their composite materials, elastomers, carbon fiber composite materials, etc. all play an important role in achieving the goal of automobile weight reduction. Among them, PMMA is widely used in many positions of the car body due to its excellent optical performance, light weight and good weather resistance. It is an important field in which PMMA application is gradually started. lamp: The lamp plays the role of lighting and signal, and the material is required to have good light transmittance, impact resistance and aging resistance. PMMA is widely used in new energy vehicle taillight lampshades due to its light weight, easy coloring and beautiful appearance. Window glass: Windows account for a large proportion of the car as a whole, so the use of low-density, light-weight materials as windows is an important means of driving weight reduction. Car windows have high requirements for light transmission, impact resistance, weather resistance and less debris. While PMMA meets the above conditions, it also has the effects of anti-ultraviolet radiation and anti-aging and weathering. Therefore, it has been used by most European car manufacturers. Used as a windshield material for the side and back of a car, the weight can be reduced by 40% to 50% compared with traditional glass. Dashboard: PMMA has excellent toughness, best toughness, high impact strength, no cracking resistance to vibration, no cracking after pressure test, good strength, good optical transparency, and no cracking when used as a dashboard. Bumper: PMMA and ABS composite materials can be used as new energy vehicle bumpers. It combines PMMA's scratch resistance, not easy to fade, environmental protection and ABS impact resistance, good temperature resistance, good electrical properties, easy to spray, etc., and is better than magnesium The aluminum alloy cost is lower. Analysis on Future Development Trend of PMMA

PMMA not only has good mechanical strength and certain chemical stability, but also has excellent optical transmittance and can be widely used in various fields. At present, the synthesis direction of polymethyl methacrylate is mainly committed to improving its heat resistance and processing fluidity, optimizing PMMA process route, effectively improving its heat resistance and processing fluidity, ensuring product performance and cost advantages, and meeting market requirements.

In the future, the market potential demand for high-precision and cutting-edge PMMA products will increase. Research will also start with the modification of PMMA. In short, with the progress of science and technology, the application field of PMMA will be more and more extensive, so the in-depth development and research on its synthesis direction and application field is still very valuable.

Source: New Materials Research Society * Disclaimer: The content contained in the content comes from the Internet, WeChat public account and other public channels, we maintain a neutral attitude towards the views in the article. This article is for reference only. The copyright of the reprinted manuscript belongs to the original author and the organization. If there is any infringement, please contact Huayi Tianxia Customer Service to delete it.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)