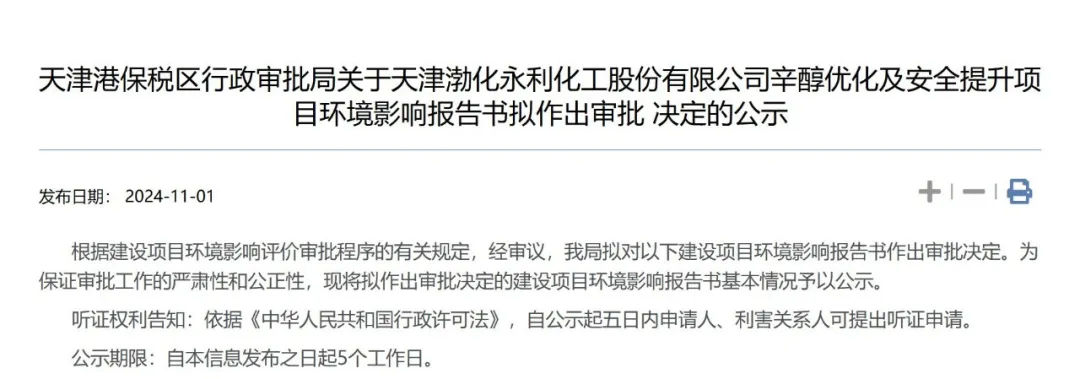

On November 1, the Administrative examination and approval Bureau of Tianjin Port Free Trade Zone announced the proposed examination and approval decision on the environmental impact report of the octanol optimization and safety improvement project of Tianjin Bohai Chemical Yongli Chemical Co., Ltd. Name of construction project: octanol Optimization and Safety Promotion Project name of Employer: tianjin Bohua Yongli Chemical Co., Ltd. Construction site: no. 3369, Bohai No.10 Road, Lingang Area, Tianjin Port Free Trade Zone overview of construction project: using the reserved open space in the west of the existing plant area, purchase one set of octanol plant, one set of PSA gas making plant (the PSA unit in the existing ammonia plant is changed to standby) and supporting facilities to form an additional production capacity of 450000 tons of octanol and 50000 tons of isobutyraldehyde per year. At the same time, the existing methanol plant will be shut down (in which the conversion and acid removal processes will continue to operate to supply synthesis gas to the newly built octanol plant of this project), and the methanol required for the production of existing polyoxymethylene and acetic acid will be purchased. After the completion of the project, the existing project in addition to the production of methanol products, the rest of the product capacity are unchanged. The investment in environmental protection is 78 million yuan, accounting for 6.5 of the total investment. It is mainly used for pollution prevention and control during the construction period and waste gas collection, wastewater treatment, noise pollution prevention and control, solid waste collection and temporary storage, environmental risk prevention and other measures during the operation period. on the morning of May 26, 2024, Bohai Chemical Yongli Company held the commencement ceremony of octanol optimization and safety improvement project in Lingang Bohai Chemical Park. The EPC general contractor of the project, Bohai Chemical Engineering Company, and the heads of construction and supervision units such as Sinochem No.6 Construction, Sinochem No.13 Construction and Bohua Supervision attended the ceremony and delivered speeches.

The octanol optimization and safety improvement project is planned to complete the civil construction before December 31, 2024, realize the intermediate handover before October 31, 2025, and start production before December 31. On May 17, 2024, the "Tianjin Bohai Chemical Yongli Chemical Co., Ltd. Octanol Optimization and Safety Improvement Project" will be publicized before the environmental impact report is submitted for approval. Industrial Chain Structure and Downstream Application of Octanol

octanol, the chemical name is isooctanol or 2-ethylhexanol, is a colorless flammable liquid with a special smell, widely used in the chemical industry. As an important chemical raw material, the downstream industry chain of octanol covers plasticizers, adhesives and other special plasticizers and other industries. Among them, the plasticizer industry is the largest downstream market for octanol, accounting for about 80% of the total demand for octanol.

In the plasticizer industry, dioctyl phthalate (DOP) and dioctyl terephthalate (DOTP) are the main derivatives of octanol. DOP by octanol and phthalic anhydride through esterification reaction, widely used in polyvinyl chloride ester, acetate resin, ABS resin and rubber and other high polymer processing, is the manufacture of artificial leather, rolling film, cable and other products of the key raw materials. DOTP is prepared by the reaction of octanol and purified terephthalic acid (PTA). It also has a wide range of plasticizing applications and can be used for the production of artificial leather films and the plasticization of acrylonitrile derivatives, polyvinyl butyral, rubber, etc. In addition, octyl acrylate, as an important raw material in the fields of adhesives and plastic modifiers, is also prepared by the esterification of acrylic acid and octanol. Other specialty plasticizer products, such as isooctyl adipate, trioctyl trimellitic acid, etc., although the demand is relatively small, but also occupy an important position in the octanol industry chain.

The preparation process of octanol mainly includes acetaldehyde condensation method and carbonyl synthesis method. Acetaldehyde condensation method to acetaldehyde as the main raw material, through condensation, hydrogenation and other reactions to produce isooctanol; and the law of carbonyl synthesis to propylene as the main raw material, adding synthesis gas through the carbonyl synthesis, condensation, hydrogenation and other reactions to produce isooctanol. These two processes have their own advantages and disadvantages, and together constitute the production system of octanol.

Domestic Market Supply and Demand Pattern and Import Dynamics of Octanol

in the first nine months of 2024, the supply and demand pattern of the domestic octanol market showed a new trend of change. On the one hand, the concentrated release of octanol production capacity expansion led to a substantial increase in supply; on the other hand, the pace of expansion in the downstream industry was relatively slow, and the growth rate of octanol demand failed to keep up with the increase in supply, resulting in a tightening of the overall supply and demand pattern. After the middle of the year, the demand for imported goods showed a downward trend, but some foreign sources maintained a stable input to the domestic market through price competition and cost advantage.

Specifically, during February-May, due to the operator's strong expectation of the recovery of market prosperity in the first half of the year, it is expected that the procurement demand of downstream factories will pick up intensively after March, and the gap of octanol supply side may be enlarged. As a result, some foreign traders and downstream factories are actively seeking low-cost imports, resulting in an increase in imports. However, in the late third quarter, with the downstream industry demand end repair and the new production capacity of octanol production progress is less than expected, the shortage of octanol supply situation again highlighted. At this point, the imports were then effectively replenished, and the overall trend was not decreasing but increasing.

As domestic octanol production capacity is put into production and gradually released, the industry will gradually evolve from a tight balance pattern to a normal state of production capacity. Although foreign sources may continue to supplement and regulate the domestic market due to the relatively stable volume of some long-term orders and price advantages, it is expected that the overall import dependence will continue to decrease in the future. At the same time, with the rising pressure of overcapacity, the domestic octanol market will face a more intense competitive environment. Therefore, octanol producers need to pay close attention to market dynamics and flexibly adjust production and sales strategies to meet future market challenges.

Source: Tianjin Port Free Trade Zone, Olefin and High-end Downstream, Chemical Easy World* Disclaimer: the content contained in the Internet, WeChat public number and other public channels, we maintain a neutral attitude to the views in the article. This article is for reference only, exchange. The copyright of the reprinted manuscript belongs to the original author and organization. If there is infringement, please contact the customer service of Huayi World to delete it.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)