Tianchen Qixiang Nylon New Material Phase I Project has been put into production in Zibo. The adiponitrile produced has broken the foreign technical blockade and made China's nylon 66 industry chain eat "domestic flour". The second phase of Tianchen Qixiang Nylon New Material Project is expected to start in the second half of this year. After it is put into production, the safety and stability of the domestic nylon 66 industry chain supply chain will be greatly improved. Relying on the large-scale production base of hexanedinitrile, Zibo will eventually form a hundred billion-level high-end nylon new material industry chain.

It is reported that the total investment of Tianchen Qixiang new materials project is 22.7 billion yuan, of which the first phase project investment is 10.4 billion yuan, and the second phase project investment is 12.3 billion yuan. Both phases of the project are listed as "provincial major projects".

In August 2019, Tianchen Qixiang laid the foundation for the 1 million-ton/year nylon 66 new material industry base project. The planned scale of the project is to produce 1 million tons of nylon new material, 500000 tons of hexamethylene diamine, 500000 tons of adiponitrile and 500000 tons of acrylonitrile in parallel. The project adopts the butadiene synthesis technology of adiponitrile independently developed by the company, which is the first patented technology with independent intellectual property rights in China. The first phase of the project has been put into operation in 2022.

Localization of adiponitrile

hexanedinitrile is the core raw material for the production of nylon 66, is a key link in the polyamide and special polyurethane industry chain, however, in the past only a few Western multinational companies to master the key production technology of hexanedinitrile, and the implementation of deep monopoly and comprehensive control, through the control of hexanedinitrile to control the global supply of nylon 66.

Tianchen Company began to carry out a large number of research experiments in 2011, constantly summing up experience, and developed a direct hydrocyanation of butadiene to synthesize adiponitrile technology with independent intellectual property rights. On September 28, 2015, it passed the appraisal of scientific and technological achievements organized by the China Petroleum and Chemical Industry Federation, and the technical level reached the domestic leading level. Subsequently, 50 tons/year adiponitrile pilot test and 2000 tons/year adiponitrile pilot test were carried out, which laid a good foundation for the construction of industrial demonstration equipment. In May 2020, Tianchen Qixiang nylon new materials project started in Zibo, Shandong Province, and in July 2022, the first phase of the project's key device hexanedinitrile device successfully produced superior products. In February 2023, the nylon 66 device was successfully driven once and produced the first batch of excellent products. In April 2024, adiponitrile was successfully selected into the Product Manual of Scientific and Technological Innovation Achievements of Central Enterprises (2023 Edition). The construction of the project has completely broken the foreign technical blockade and monopoly of adiponitrile in China, filled the gap in domestic technology and industry, and made the price of related products quickly fall from more than 80000 yuan to 20000 yuan per ton, which is of great significance to promote the long-term, safe and healthy development of China's high-end polyamide industry.

In May 2024, Tianchen International Trade Company jointly with Tianchen Qixiang Company completed the first export of its own technology butadiene method into hexanediamine, marking that Tianchen Company's butadiene method production of hexanedinitrile process has been fully recognized by the overseas market. At present, in addition to hexamethylene diamine, Tianchen International Trade Company also takes the initiative to attack and plan the layout in the export business of nylon 66, caprolactam, amine sulfate and other products.

In the next step, Tianchen Company will focus on the scientific and technological achievements of new materials such as nylon 6, nylon 66 and propylene oxide independently developed, through the implementation of the "1 N" park-in-park model and the extension of diversified fields. Domestic Adiponitrile Capacity Construction

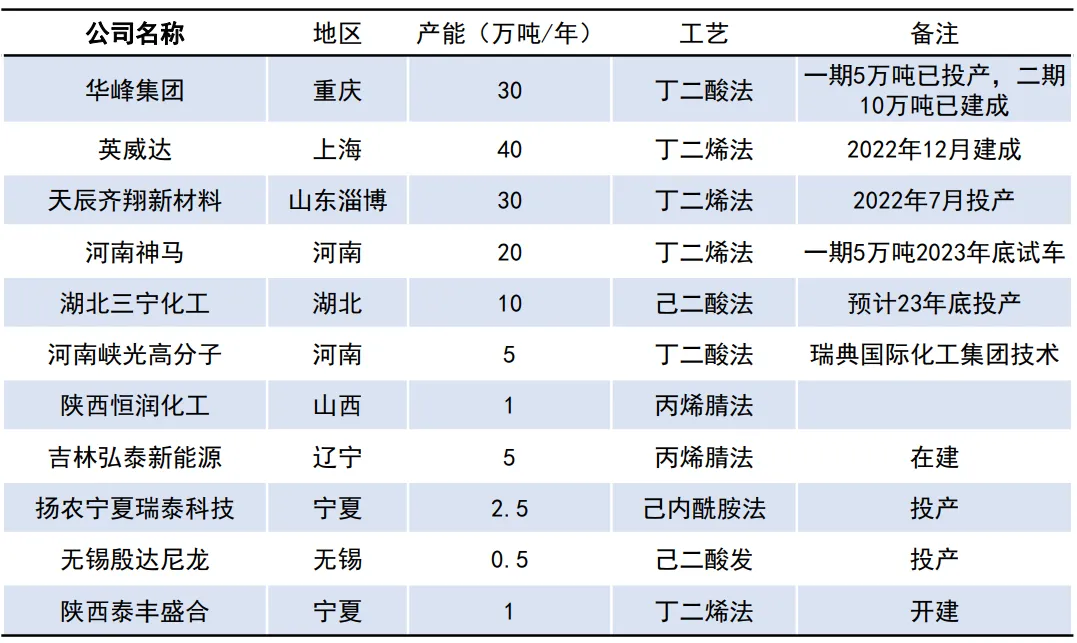

at present, the domestic pre-built production capacity of more than 2.6 million tons, the process to succinic acid method-based, new production capacity has been put into production.

Domestic adiponitrile production capacity construction (incomplete statistics)

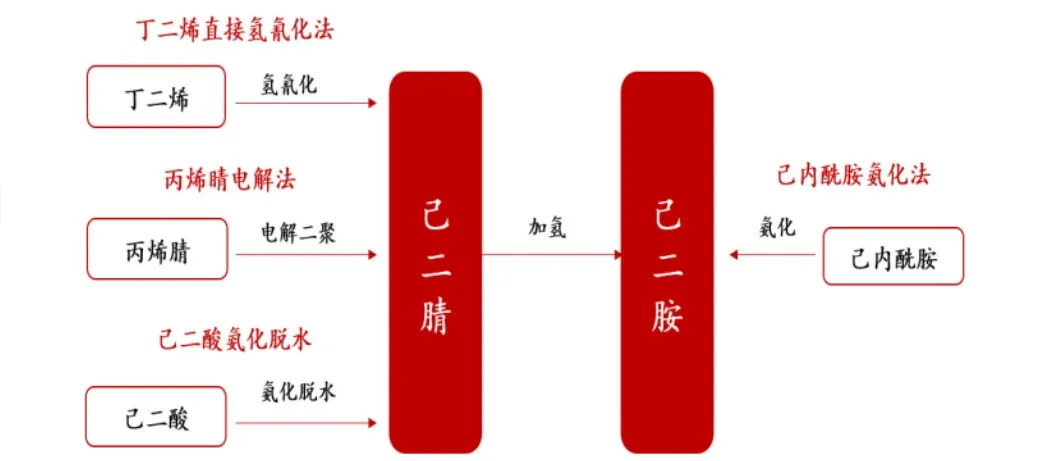

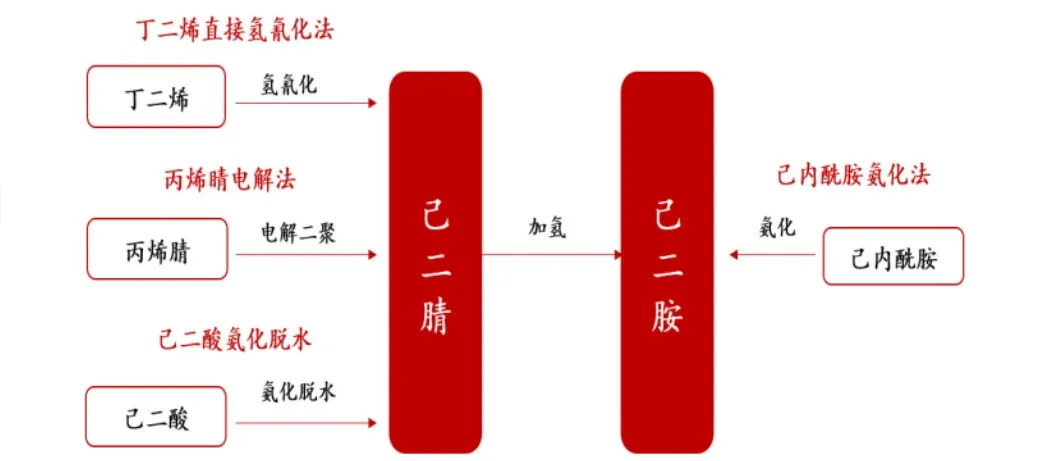

production process of adiponitrile

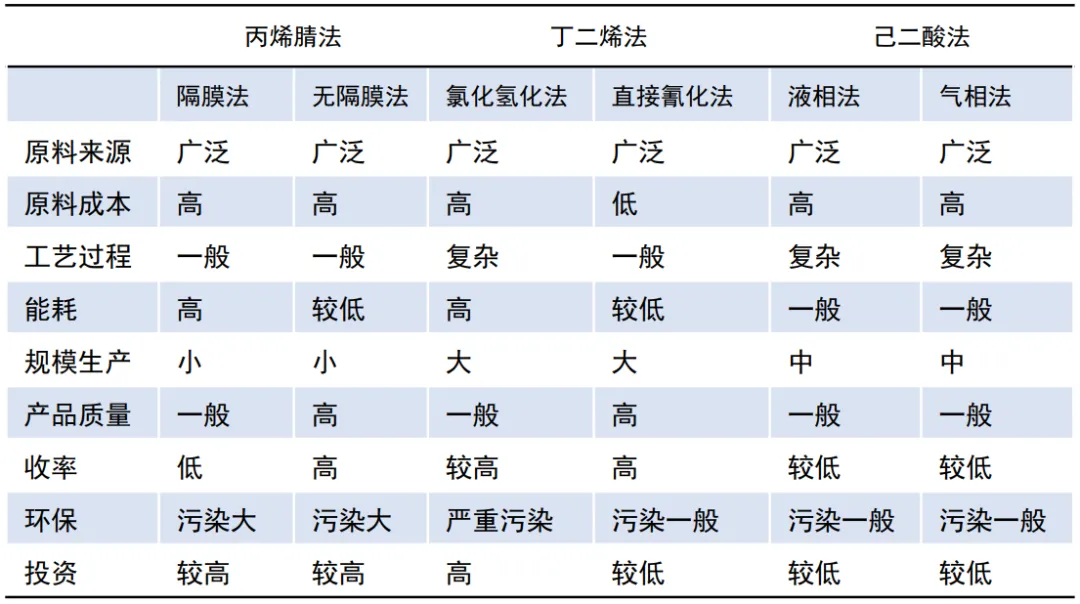

there are three methods for the industrial production of adipic acid catalytic ammoniation, acrylonitrile electrolytic dimerization and butadiene, and the domestic scale is on the ground. At present, the operating and newly-built devices basically adopt the acrylonitrile electrolytic dimerization method and butadiene method with less by-products and relatively low raw material consumption.

In terms of production technology, the investment in adipic acid method is low, but at this stage the price of adipic acid is high, and the energy consumption of adipic acid method is high, and there are more by-products, the process contains a number of processes, at present, the technology is mainly used by Huafeng Chemical, which supports a large amount of adipic acid production capacity. Acrylonitrile reaction process is only one step, the product is easy to refine and purify, but the toxicity and corrosion of acrylonitrile is strong, and the price of acrylonitrile is high, the scale of production capacity is difficult to expand. In contrast, the butadiene method has mild reaction, low energy consumption, high product yield and good quality, which is a better route at present, but the highly toxic characteristics of hydrocyanic acid have extremely high safety requirements. Comparison of Adiponitrile Production Methods

source: Plasticizing Alliance, Aibang Polymer, Ease of the World

* Disclaimer: the content contained in the Internet, WeChat public number and other public channels, we maintain a neutral attitude to the views in the article. This article is for reference only, exchange. The copyright of the reprinted manuscript belongs to the original author and organization. If there is infringement, please contact the customer service of Huayi World to delete it.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)