In the Chinese market, the production process of MMA has been developed to nearly six, and these processes have been industrialized. However, the MMA competition for different processes varies widely.

At present, the MMA mainstream production process has the following three:

acetone cyanohydrin method (ACH method): This is one of the earliest industrialized production processes, mature technology and easy to operate.

Ethylene carbonylation: This is a relatively new production process with high reaction efficiency and product quality.

Isobutene oxidation method (C4 method): This is a production process based on the oxidative dehydrogenation of butene, with readily available raw materials and low cost.

On the basis of these three processes, there are the following three improved production processes:

improved ACH method: By optimizing the reaction conditions and equipment, the yield and product quality were improved.

Glacial acetic acid method: The process uses glacial acetic acid as raw material, no three wastes are discharged in the production process, and the environment is friendly.

BASF and Lucite, which are mainly represented by the enterprise name, have made unique technological improvements according to the characteristics of their respective enterprises and have high proprietary and competitive advantages.

At present, these six production processes have been put into production in China with a scale of 10,000 tons and above. However, the competitive situation between different processes varies greatly due to their respective characteristics and costs. In the future, with the advancement of technology and the development of the market, the competitive landscape of these production processes may change.

At the same time, it is important to mention that in September 2022, the 10,000-ton coal-based methanol-acetic acid-to-methyl methacrylate (MMA) project industrial demonstration device independently developed by the Institute of Process Engineering of the Chinese Academy of Sciences was successfully started and operated stably, and the products were qualified and up to standard. This device is the world's first coal-based methanol-acetic acid MMA industry demonstration device, to achieve the domestic methyl methacrylate production from entirely dependent on petroleum raw materials to the use of coal-based raw materials.

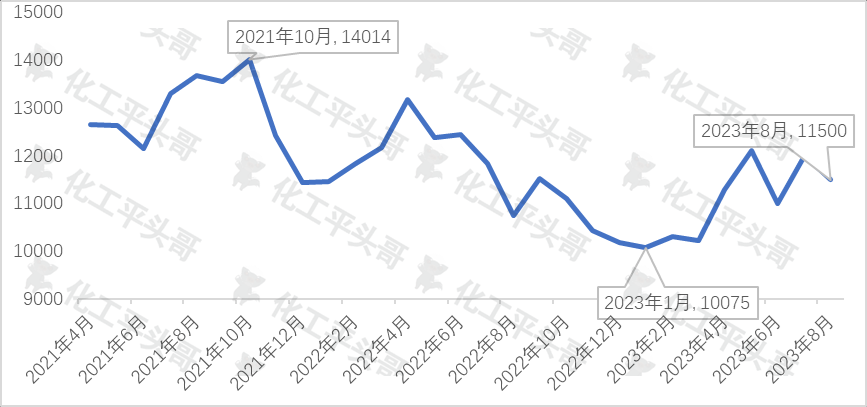

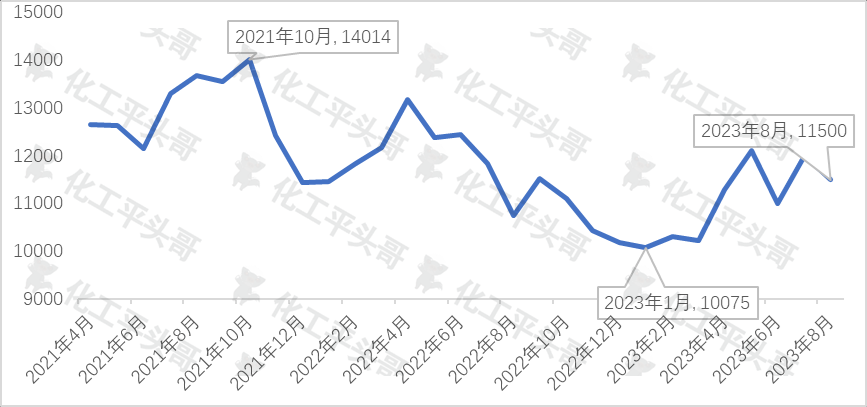

Due to the change of competition pattern, the supply and demand environment of MMA products has changed, and the price trend shows narrow fluctuation. In the past two years, the highest price of MMA in China has reached 14014 yuan/ton, and the lowest price is about 10000 yuan/ton. As of August 2023, the market price of MMA has dropped to 11500 yuan/ton. The main representative product of the downstream is PMMA, and its market price has shown a weak shock in the past two years, with the highest price of 17560 yuan/ton and the lowest price of 14625 yuan/ton. As of August 2023, the mainstream price of PMMA in China fluctuated at 14600 yuan/ton. It should be noted that since domestic PMMA products are mostly low-end brands, the price level of the products is lower than that of the imported market.

1. Without considering the acetic acid MMA device, the ethylene MMA production process has the strongest competitiveness in the past two years.

In the past two years, the ethylene-based MMA production process has the strongest competitiveness in the Chinese market. According to statistics, the production cost of ethylene MMA is the lowest and its competitiveness is the strongest. In 2020, the theoretical cost of ethylene MMA is 5530 yuan per ton, while by January-July 2023, the average cost is only 6088 yuan per ton. In contrast, the BASF method has the highest production cost. The MMA cost of the method in 2020 is 10765 yuan per ton, and the average cost in January-August 2023 also reached 11081 yuan per ton.

When assessing the competitiveness of different production processes, we need to pay attention to the differences in the unit consumption of raw materials for different processes. For example, the raw material consumption of ethylene method is ethylene 0.35, methanol 0.84, and syngas 0.38, while BASF method is essentially ethylene method, but its ethylene consumption is 0.429, methanol consumption is 0.387, and syngas consumption is 662 cubic meters. These differences affect the production cost and competitiveness of different processes.

According to the cost measurement in the past few years, the MMA competitiveness ranking of different processes is: ethylene method> C4 method> improved ACH method> ACH method> Lucite method> BASF method. This ranking is mainly affected by the utility differences of different processes.

In the future, with the advancement of technology and the development of the market, the competitive landscape of different processes may change. In particular, without considering the premise of acetic acid MMA device, ethylene MMA is expected to continue to maintain its competitive advantage.

2, acetic acid method MMA is expected to become the most competitive production mode.

The Institute of Process Engineering of the Chinese Academy of Sciences has successfully developed the world's first coal-based methanol-acetic acid MMA industrial demonstration device, which uses methanol and acetic acid as raw materials, through aldol condensation, hydrogenation and other processes, to achieve long-term stable production of MMA products. The process is obviously advanced, not only the process is short, but also the raw material comes from coal, which has obvious cost advantages. In addition, Xinjiang Zhongyou Puhui Technology Co., Ltd. is planning a large-scale industrial installation of 110000 tons/year, which will further promote the upgrading and development of China's MMA industry. Compared with the traditional petroleum-based MMA production process, the acetic acid MMA process is more environmentally friendly and has more obvious economic advantages, which is expected to become an important development direction of the MMA industry in the future.

3. There are significant differences in the cost impact weights of different processes

there are significant differences in the cost impact weights of different MMA production processes, and the impact weights of different factors on cost vary from process technology to process technology.

For MMA of ACH method, the price change of acetone, methanol and acrylonitrile has great influence on its cost. Among them, the price change of acetone has the greatest impact on the cost, reaching 26%, while the price change of methanol and acrylonitrile affects 57% and 18% of the cost respectively. In contrast, the cost of methanol accounts for only about 7%. Therefore, in the value chain study of MMA by ACH method, the cost change of acetone needs to be considered more.

For C4 MMA, high purity isobutylene is the largest variable cost, accounting for about 58% of MMA costs. Methanol accounts for about 6% of MMA costs. The price fluctuation of isobutene has a great influence on the cost of C4 MMA.

For ethylene MMA, ethylene consumption constitutes more than 85% of the MMA cost of this process, which is the main cost impact. However, it should be noted that most of the ethylene is self-produced and supporting production, and the internal settlement is mostly based on cost price settlement, so the theoretical competitiveness level of ethylene may not be as good as the actual competitiveness level.

In summary, there are significant differences in the weight of different factors on cost in different MMA production processes, which need to be analyzed according to the specific process technology.

4. Which MMA production process will be the lowest cost in the future?

Under the premise of the current state of technology, the level of MMA competitiveness of different processes in the future will be significantly affected by fluctuations in raw material prices. The raw materials used in several major MMA production processes include MTBE, methanol, acetone, sulfuric acid and ethylene, which can be purchased or supplied internally, while synthesis gas, catalysts and accessories, hydrocyanic acid, crude hydrogen, etc. are self-supplied by default and the price remains unchanged.

Among them, the price of MTBE mainly follows the trend fluctuation of the refined oil market, and the price of refined oil is closely related to the price of crude oil. MTBE prices are also expected to show an upward trend on the premise that future oil prices are expected to be bullish, and the expected rally is stronger than crude oil. The price of methanol market fluctuates with the trend of coal price, and the supply is expected to continue to increase significantly in the future, but the development of the industrial chain model will lead to an increase in the downstream ownership rate, and the price of commodity methanol market is expected to continue to rise.

The supply and demand environment in the acetone market is deteriorating, while new projects under the ACH method are blocked and long-term price volatility is likely to be relatively weak. And ethylene is mostly internal self-supply, the price competitiveness is strong.

Therefore, according to the current state of technology and the fluctuation trend of raw material prices, there is still some uncertainty as to which MMA production process will have the lowest cost in the future. However, it is foreseeable that in the context of rising oil prices and coal prices in the future, the prices of raw materials such as methanol and MTBE are also expected to rise, which may have an important impact on the level of MMA competitiveness of different processes. In order to remain competitive, manufacturers may need to seek more economical and efficient raw material supply channels, while strengthening the optimization and innovation of production processes to reduce production costs and improve product quality.

in the future, the competitiveness of different MMA processes in China is ranked as follows: ethylene method is expected to remain strong, followed by ACH method with acrylonitrile plant, and C4 method again. However, special attention should be paid to the fact that in the future, enterprises will develop in an industrial chain mode, which will be the most competitive mode of operation through the development of low-cost by-products and downstream supporting PMMA or other chemical products.

The reason why the ethylene process is expected to remain strong is that its raw material ethylene is more available and accounts for a very high proportion of MMA production costs. However, it should be pointed out that most of the ethylene is internally supplied, and its theoretical competitiveness level may not be as good as the actual competitiveness level.

The ACH process has strong competitiveness in the case of supporting acrylonitrile plant, mainly because high-purity isobutylene as the main raw material accounts for a relatively large proportion of the cost of MMA, while the ACH process can by-produce high-purity isobutylene, thereby reducing costs.

The competitiveness of processes such as the C4 process is relatively weak, mainly due to the large price fluctuations of its raw materials isobutane and acrylonitrile, and the relatively low proportion of isobutane in MMA production costs.

In general, the most competitive operation mode of MMA industry chain in the future will be the development of enterprises in the industrial chain mode, through the low cost of by-products and downstream supporting PMMA or other chemical products. This can not only reduce production costs and improve product competitiveness, but also better meet market demand.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)