-

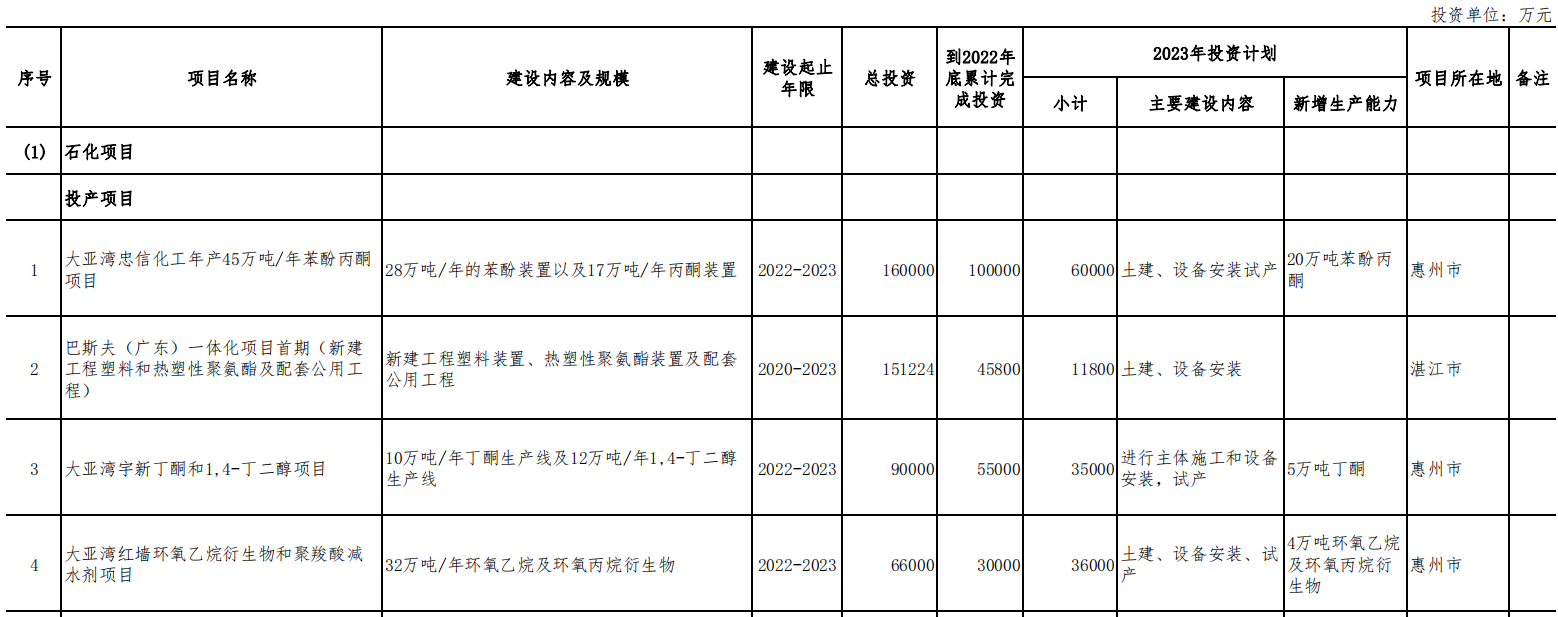

On March 13, BASF's Zhanjiang integrated base's new production complex has broken ground, which includes glacial acrylic acid (GAA) plant, butyl acrylate (BA) plant and 2-ethylhexyl acrylate (2-EHA) plant.

-

2022 October 11, BASF plans in China's Zhanjiang integration base to invest in a new world-class scale new pentyl glycol (NPG) plant, the annual output of 80000 metric tons, the plant is expected in 2025 the fourth quarter of production.

-

On September 16, 2022, the company's construction of BASF (Guangdong) integrated base project EOEG device started.

-

2022 September 15, China National Chemical Engineering Corporation and BASF Group in Guangdong Zhanjiang signed a construction partnership framework agreement.

-

On September 6, 2022, the first unit of BASF Zhanjiang Integrated Base was officially put into operation. Since then, BASF will increase its production of modified engineering plastics by 60000 tons per year for the Chinese market, increasing the total production capacity of this product in the Asia-Pacific region from 2023 to 420000 tons.

2, Donghua Maoming Alkane Comprehensive Utilization Project Phase I (Ⅰ)

It is reported that Donghua Energy (Maoming) Alkane Resources Comprehensive Utilization Project Phase I (I) has been fully transferred to the commissioning preparation stage on December 26 last year. At present, it is accelerating the phase of purging and electrical instrument commissioning, and will be officially put into production.

Donghua Energy (Maoming) Alkane Resources Comprehensive Utilization Project is planned to be implemented in three phases. Currently, the first phase (I) project is under construction, which consists of five sub-projects, they are the first phase (I) of the industrial project (1 set of 600000-ton/year propane dehydrogenation unit, 1 set of 400000-ton/year polypropylene unit and 1 set of 200000-ton/year ammonia synthesis unit), the first phase of the supporting reservoir area, the 1# and 2# liquid bulk berth project of the East Second Port Pool, the supporting pipe gallery project and the supporting heavy cargo terminal project.

3, ExxonMobil Huizhou Ethylene Project

On March 8, ExxonMobil Huizhou ethylene project LDPE plant first large equipment degassing warehouse successfully hoisted in place, marking the project construction from the civil phase into the installation phase.

In November 2021, the total investment of about 10 billion US dollars ExxonMobil Huizhou ethylene project comprehensive construction activities in Huizhou Daya Bay, Beijing, Houston, the United States at the same time, marking the project production equipment into a comprehensive formal construction stage.

ExxonMobil Huizhou Ethylene Project is one of the major national foreign investment projects, located in Huizhou Daya Bay Petrochemical Park. The total investment of the project is over 10 billion US dollars, and it is planned to be constructed in two phases. The first phase of the project mainly includes ethylene plant and high-end polyethylene, polypropylene and other production equipment in the middle and lower reaches, as well as supporting public works, wharf, storage and transportation and environmental protection facilities. The production of a variety of high-end chemical products can meet customers' needs in packaging, automobiles, Industrial and consumer goods, health and personal care products and other applications.

4. CNOOC Huizhou Phase III Ethylene Project. According to the Hydrocarbon Engineering on March 21, 2023, Dessinib Energy signed a contract for CNOOC and Shell (CSPC) Huizhou Phase III project. The project is a large liquid ethylene cracker.

Desinib will provide patented technology for the 1.6 million t/a ethylene plant of CSPC and complete the process design. In addition to providing ethylene cracker technology, completing the low-emission furnace design, and electrification of the main compressor, Decinib will also provide other key patented technologies, such as heat integrated rectifier system (HRS), corrugated tray™and waste alkali treatment plant. Cracking furnace with super-selective conversion of Dexinib (USC®) U and W coil furnace technology.

, the total investment of the Huizhou Phase III ethylene project of CNOOC and Shell is about 5.6 billion US dollars (about 39.6 billion yuan), which is located in Daya Bay Petrochemical Zone. On the basis of 1 million tons/year ethylene in the first phase and 1.2 million tons/year ethylene in the second phase, the scale of 1.6 million tons/year ethylene in the third phase is added, of which α-olefin, poly α-olefin and metallocene polyethylene technologies are applied for the first time in the Asia-Pacific region. The estimated output value of the project is about 38.2 billion yuan/year after it is put into operation. The third phase of the ethylene project is based on a total of 2.2 million tons/year of ethylene in the first two phases. After the completion of the project, the total ethylene production capacity of CSPC will reach 3.8 million tons/year.

5, Zhongke Refining 100000 tons EVA project.

On August 29, 2022, Zhongke Refining and Chemical New No. 2 EVA Project Environmental Impact Report was submitted for approval before publicity.

It is reported that the total investment of the project is 1.94 billion yuan, and a new 100000-ton/year EVA device is built, with a construction period of 24 months. The main products are EVA (ethylene-vinyl acetate copolymer) with different VA content. There are 12 product brands, all of which are sold as commodities. The main raw materials of ethylene and propylene are directly transported by the ethylene plant of Zhongke (Guangdong) Refining and Chemical Co., Ltd., and vinyl acetate is provided by Sinopec's unified layout. The device adopts Lyondellbasell's autoclave polymerization process technology.

source: eighth element plastic version. * Disclaimer: The content comes from the Internet, WeChat public accounts and other public channels, we maintain a neutral attitude towards the point of view. This article is for reference only, exchange. The copyright of the reproduced manuscript belongs to the original author and institution. If there is any infringement, please contact the customer service of Huayi World to delete it.  Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)