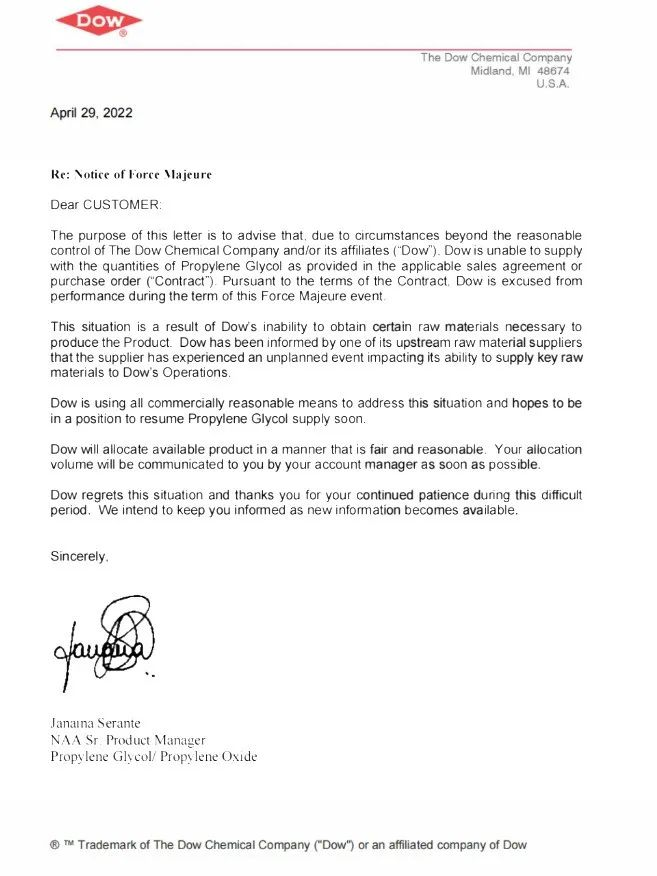

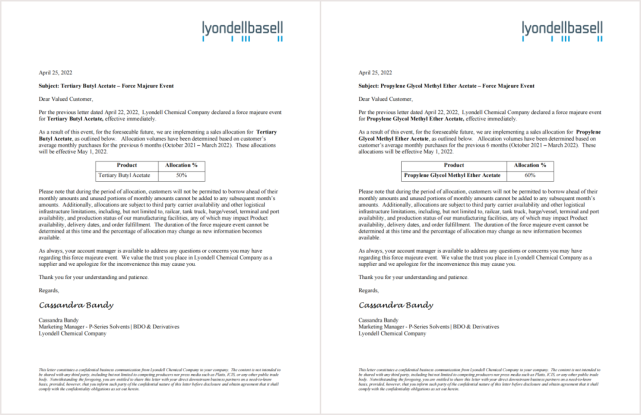

Recently, Dow issued an emergency notice saying that due to the accident of a supplier of upstream raw materials, its ability to supply key raw materials to Dow's business was interrupted. Therefore, tao announced that propylene glycol was stopped due to force majeure, and the recovery time was notified later.

Due to the supply problem of Dow, the supply crisis of chemical giants in the chemical industry chain was triggered.

On May 5, 2022 local time, BASF announced in a letter to customers that due to an uncontrollable event occurred in BASF Tao HPPO, an important propylene oxide supplier, it will not be able to deliver the expected amount of propylene oxide to BASF. So BASF Polyurethane Co., Ltd. must announce that polyether polyols and polyurethane systems are difficult to supply in the European market.

At present, BASF can neither ensure the existing orders in May nor confirm any orders in May or June.

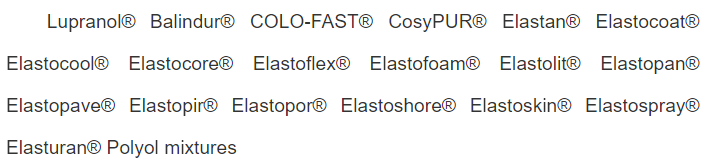

List of affected products:

Many international chemical giants stopped supply

in fact, this year under the influence of the global energy crisis, many international chemical enterprises have announced the suspension of supply.

On April 27, American energy giant Exxon Mobil said that its Russian subsidiary Exxon Neftegas had announced that the operation of its "Sakhalin 1" oil and gas project was affected by force majeure, the reason is that the sanctions against Russia make it more and more difficult to deliver crude oil to customers.

The "Sakhalin 1" project produces Sokol crude oil on the coast of Sakhalin Island in the Far East of Russia, exporting about 273,000 barrels per day, mainly to South Korea, as well as other destinations such as Japan, Australia, Thailand and the United States.

After the outbreak of the conflict between Russia and Ukraine, Exxon Mobil announced on March 1 that it would withdraw about US $4 billion from its assets and stop all its business in Russia, including "Sakhalin 1".

At the end of April, the five major factories of INIX announced that the delivery suffered force majeure. In a letter to customers, innix said that all polyolefin products related to railway restrictions in the enterprise were affected by force majeure, it is expected to be required to limit railway transportation below its best average daily rate.

The force majeure polyolefin products include:

318,000 tons/year high density polyethylene (HDPE) plant at Cedar Bayou factory in Texas;439,000 tons/year polypropylene (PP) plant at Bayou factory in Texas Chocolate;794,000 tons/year high density polyethylene (HDPE) plant in Deer Park, Texas;147,000 tons/year polypropylene (PP) plant at Deer Park plant in Texas;230,000 tons/year polystyrene (PS) device in Carson, California.

In addition, Ineos Olefins & Polymers earlier this month, the PP plant in Carson, California has not resumed operations due to power failure and manufacturing.

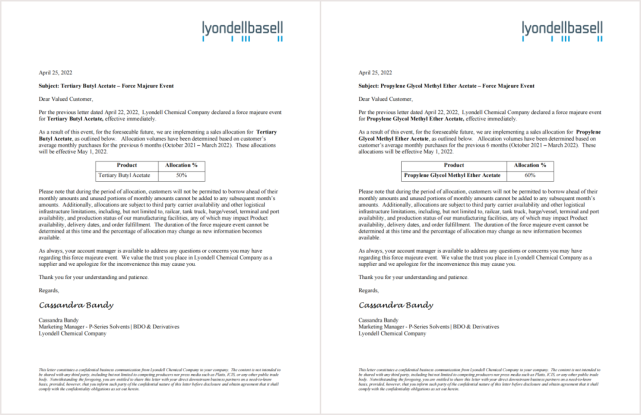

It is worth noting that, in April, chemical giant liendbassel also issued several announcements due to force majeure factors such as mechanical failure, including acetic acid raw materials, tert-butyl acetate, and EBA (DBA) and other products are in short supply.

On April 15, a mechanical failure occurred in the carbon monoxide supply system of acetic acid raw material in La Porte, Texas.

On April 22, it was announced that products such as tert-butyl acetate and EBA (DBA) were affected by force majeure.

On April 25, liendbassel issued a quota sales notice: the company is implementing the sales distribution of tert-butyl acetate, tartan and other products.

The notice shows that the allocation amount is determined according to the average monthly purchase amount of the customer in the past 6 months (October 2021-march 2022), and the plan will take effect from May 1, 2022. The news indicates that the above raw materials will be supplied in limited quantities according to the customer's previous purchase volume.

Shutdown of many domestic chemical enterprises

from a domestic perspective, many chemical leaders have also entered the period of parking and maintenance one after another. It is estimated that 5 million tons of production capacity will "evaporate" and the supply of raw materials will be affected.

In May this year, the planned overhaul capacity of domestic PP market was 2.12 million tons, and the overhaul types were mostly oil-based enterprises; In addition, Yangzi Petrochemical (80,000 tons/year) was expected to drive on May 27 for the overhaul enterprises left in April to May; hainan Refinery (200,000 tons/year) is expected to start on May 12.

PTA: Parking and overhaul of 1.2 million tons PTA device in Sanfang Lane; Parking and overhaul of 2.2 million tons PTA device in Hengli Petrochemical line 1.

Methanol: Shandong Yangmei Hengtong has an annual output of 300,000 tons of methanol to olefin plant and a matching 250,000 tons/year methanol plant. It is planned to stop and overhaul on May 5, which is expected to last for 30-40 days.

Ethylene glycol: a set of 120,000 tons/year synthesis gas ethylene glycol plant in Inner Mongolia is planned to be closed for overhaul in mid-May, and the estimated duration is about 10-15 days.

TDI: The 120,000-ton device of Gansu Yinguang is stopped for overhaul, and the resumption time is not fixed; The 3,50,000-ton device of Yantai Juli is stopped for overhaul, and the resumption time is not fixed.

BDO: Xinjiang Xinye's annual output of 60,000 tons BDO device was overhauled on April 19, and it is expected to restart on June 1;

PE: stop and overhaul of haiguolong oil PE device

liquid ammonia: Hubei chemical fertilizer liquid ammonia plant parking overhaul; Jiangsu Yizhou science and technology liquid ammonia plant parking overhaul.

Hydrogen peroxide: Jiangxi Lantai hydrogen peroxide parking and maintenance today

hydrofluoric acid: Fujian Yongfu chemical hydrofluoric acid device is stopped for maintenance, and the manufacturer's anhydrous hydrofluoric acid is temporarily not quoted.

In addition, the epidemic has led to the shutdown of many enterprises. For example, the whole city of Jiangyin city in Jiangsu province is managed by referring to the "control area". Important places in the industry such as Huahong village and textile market are directly listed as closed control areas, and hundreds of outlets in the textile market are all closed. Zhejiang, Shandong, Guangdong and pearl-Delta region, as well as Shanghai and the surrounding Yangtze River Delta region, many major chemical provinces and major electronic towns have been affected, and low-load starts are everywhere. Cars, the start-up transportation of electronics and other manufacturing industries also had to be suspended.

Under the influence of force majeure factors such as logistics obstruction, multiple sealing and control, construction restriction, and chemical giant's supply interruption, the price of chemical raw materials continues to soar. In the future, the price of raw materials will still be at a relatively high level, so everyone should hurry up to stock up.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)