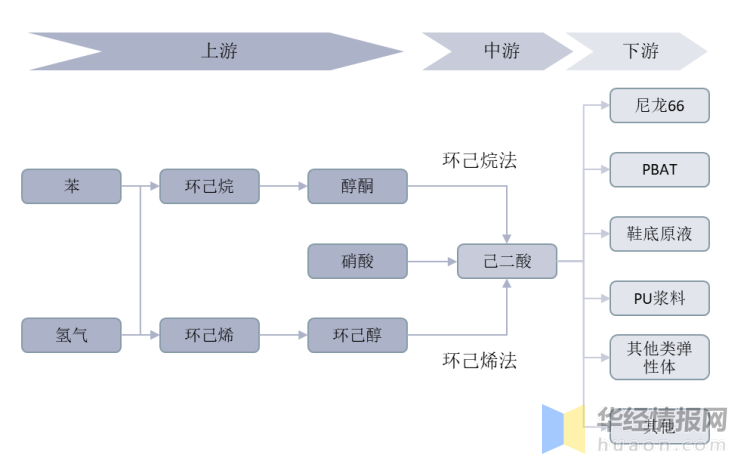

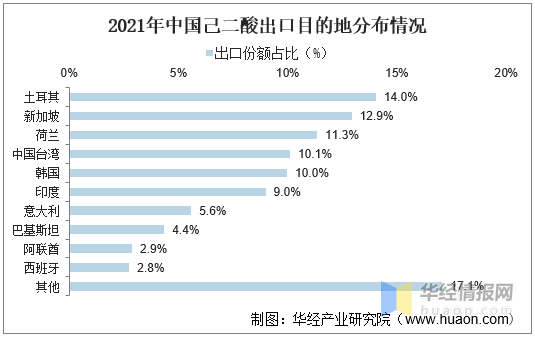

Adipic acid industry chain

adipic acid is a dicarboxylic acid of great significance in industry, which can produce various reactions, including salt formation reaction, Ester reaction, amidation reaction, etc. It is used to produce nylon 66 fiber and nylon 66 resin, the main raw materials of polyurethane and plasticizer play an important role in chemical production, organic synthesis industry, medicine, lubricant manufacturing, etc. Adipic acid production process is mainly divided into phenol method, butadiene method, cyclohexane method and cyclohexene method. Currently, phenol method has been basically eliminated, and butadiene method is still in the research stage. At present, the industry processes are mainly cyclohexene and cyclohexene, and the raw materials are benzene, hydrogen and nitric acid.

Adipic acid industry chain

source: Public Data arrangement

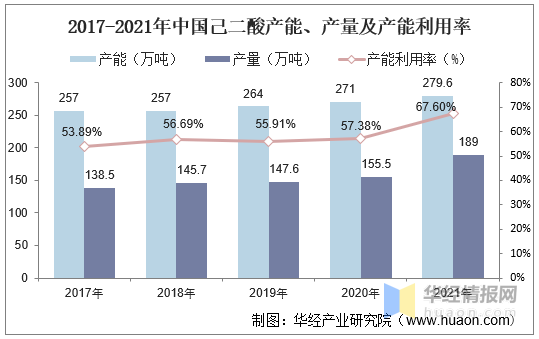

current situation of adipic acid industry

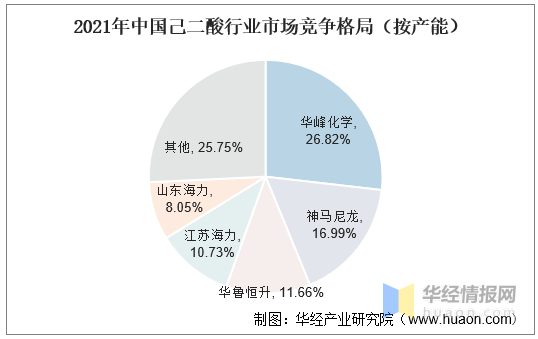

from the domestic adipic acid supply side, the production capacity of adipic acid in China is growing slowly, and the output is growing slowly year by year. According to statistics, in 2021adipic acid production capacity was 2.796 million tons/year, adipic acid production was 1.89 million tons, an increase of 21.53% year-on-year, and the capacity conversion rate was 67.60%.

Capacity, output and capacity utilization rate of adipic acid in China from 2017 to 2021

source: Public Data arrangement

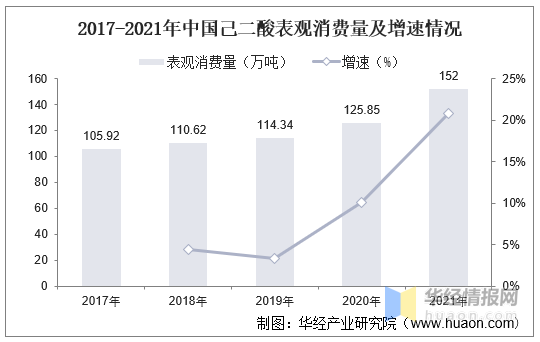

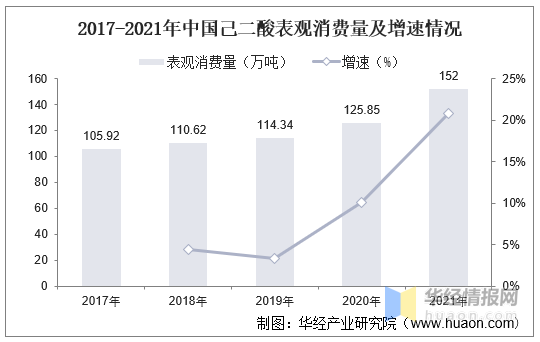

from the demand side, the apparent consumption of adipic acid increased steadily year by year from 2017 to 2020. According to statistics, in 2021, the demand of downstream PU slurry recovered, and the apparent consumption of adipic acid increased rapidly, with the annual apparent consumption of 1.52 million tons, up 30.08% year on year.

Apparent consumption and growth rate of adipic acid in China from 2017 to 2021

source: Public Data arrangement

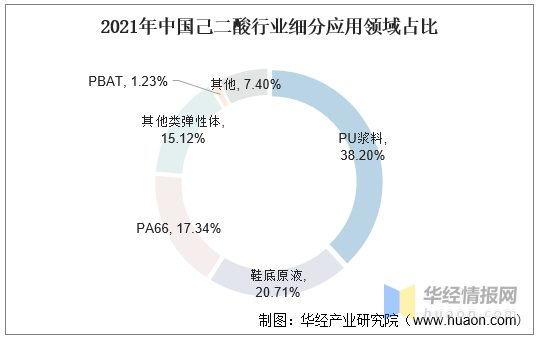

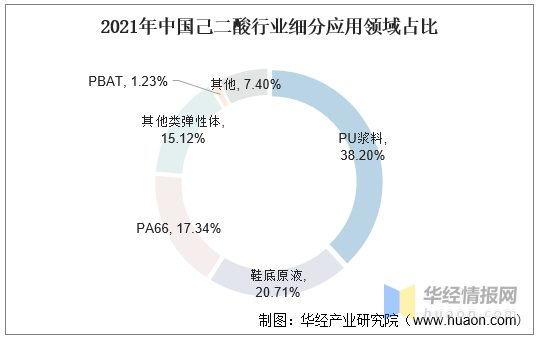

judging from the demand structure of adipic acid in China, PU slurry industry accounts for about 38.20%, sole stock solution accounts for about 20.71% of the total demand, and nylon 66 accounts for about 17.34%. International adipic acid is mainly used to produce nylon 66 salt.

Proportion of application fields of adipic acid industry in China in 2021

source: Public Data arrangement

current situation of adipic acid industry import and export

judging from the current situation of import and export, China's adipic acid exports far more than imports. As the market price of adipic acid continues to rise, the export amount rises. According to statistics, in 2021, the export quantity of adipic acid in China was 398,100 tons, and the export amount was 0.6 billion US dollars.

Quantity and amount of adipic acid exports in China, 2017-2021

source: General Administration of Customs, China economic Industry Research Institute

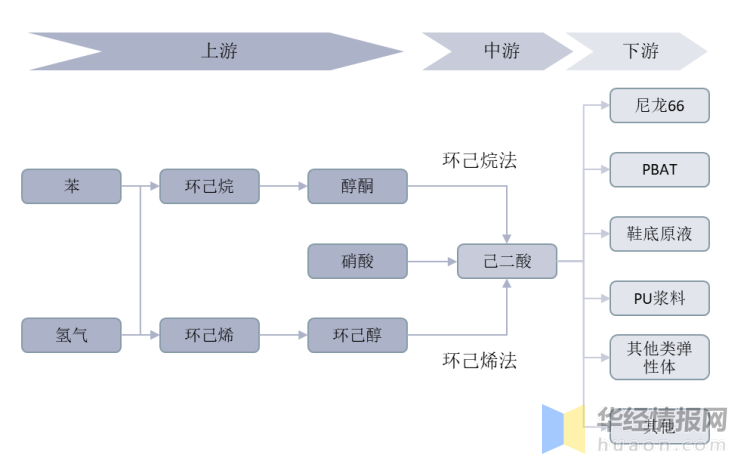

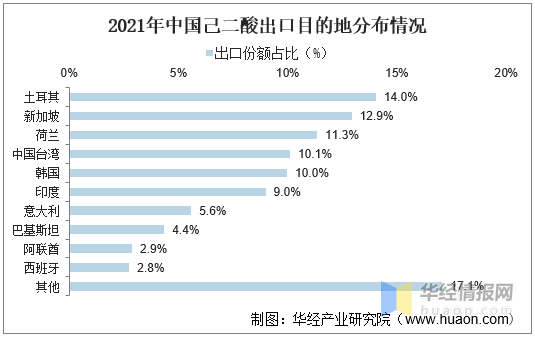

judging from the distribution of export destinations, the total export ratio in Asia and Europe reached 97.7%. Among them, the top three are Turkey accounting for 14.0%, Singapore accounting for 12.9% and Holland accounting for 11.3%.

Distribution of China's adipic acid export destinations in 2021

source: General Administration of Customs, China economic Industry Research Institute

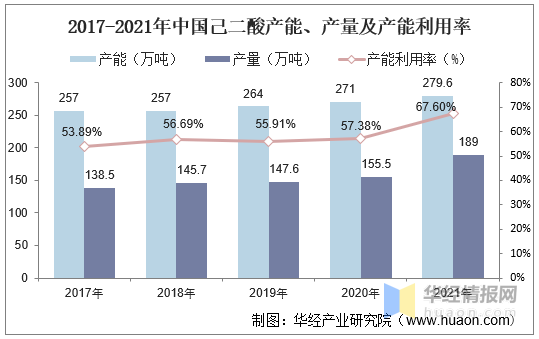

competition Pattern of adipic acid industry

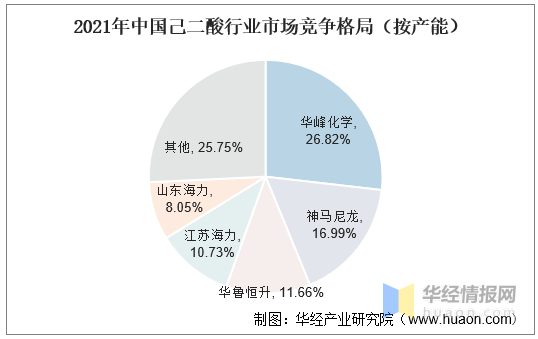

judging from the market competition pattern (by capacity), domestic adipic acid production capacity is relatively concentrated, and the total capacity of the top five adipic acid manufacturers accounts for 71% of the national total capacity. According to statistics, the CR5 situation of adipic acid in China in 2021was: Huafeng chemistry (750,000 tons, accounting for 26.82%), Shenma nylon (475,000 tons, accounting for 16.99%), Hualu Hengsheng (326,000 tons, accounting for 11.66%), Jiangsu Haili (300,000 tons, accounting for 10.73%), Shandong Haili (225,000 tons, accounting for 8.05%).

Market competition pattern of adipic acid industry in China in 2021 (by capacity)

source: Public Data arrangement

future Development Trend of adipic acid industry

1. The price difference is in the rising cycle

in 2021, affected by the rising price of downstream raw materials, the price of adipic acid showed a fluctuating upward trend. On February 5, 2022, the price of adipic acid was 13650 yuan/ton, which was at a historical high. Affected by the rising price of pure benzene, the price difference of adipic acid dropped to a historical low in the first half of 2021. since October 2021, the price of raw materials has dropped and the price difference of adipic acid has increased accordingly. On February 5, 2022, the price difference of adipic acid was 5373 yuan/ton, which was higher than the historical average.

2. PBAT and nylon 66 are put into production to stimulate demand

with the promulgation of the plastic limit order, the demand for PBAT in China has increased, and the number of projects under construction has increased. In addition, the localization of hexanitrile solves the problem of fit the neck of nylon 66 raw materials, and the production capacity of hexanitrile under construction and planning exceeds 1 million tons, the production capacity of domestic hexanitrile has accelerated, and domestic nylon 66 has ushered in a period of rapid growth in production capacity, adipic acid will usher in a new round of demand growth.

At present, the production capacity of PBAT under construction and planning exceeds 10 million tons, of which 4.32 million tons are expected to be put into operation in 2022 and 2023. One ton of PBAT consumes about 0.39 tons of adipic acid, and the demand for adipic acid is about 1.68 million tons; the production capacity of nylon 66 under construction and planning is 2.285 million tons, and a ton of nylon 66 consumes about 0.6 tons of adipic acid, forming about 1.37 million tons of adipic acid.

Source: China Economic Research Institute* Disclaimer: the content contained is from public channels such as the Internet and WeChat public accounts. We maintain a neutral attitude towards the views in this article. This article is for reference and communication only. The copyright of the reprinted manuscript belongs to the original author and organization. If there is any infringement, please contact Huanyi world customer service to delete it. Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)