At present, the domestic high-end Polypropylene Market development mainly includes: metallocene polypropylene, high melt strength polypropylene, foamed polypropylene, high transparent polypropylene, "three high and two low" polypropylene, low ash thermoforming polypropylene, high crystalline polypropylene, ultra-high molecular weight polypropylene, high gloss polypropylene, low shrinkage polypropylene, antibacterial polypropylene, etc.

Among them, pipe materials, ternary copolymer casting film materials, transparent plastic, medium and high melting high impact resistant copolymer materials, Thermoforming and thin wall injection plastics, high melting fiber materials and so on have become hot development products.

Packaging field: high temperature cooking film, capacitive film, electronic clean packaging, milky tea cup, take-out lunch box, extinction film, ternary copolymer casting film, food tray, etc;

automotive and household appliances: low-odor vehicle interior parts, automobile exterior parts, bumper, high-gloss household appliance shell, foam material, etc. mainly highlight the development of anti-impact materials of "three high and two low;

medical field: syringe, radiation-proof clothes, disposal nursing pad, mask, infusion bag, drug packaging, medical consumables, etc;

home improvement field: water pipe. Waterproof coiled material, etc;

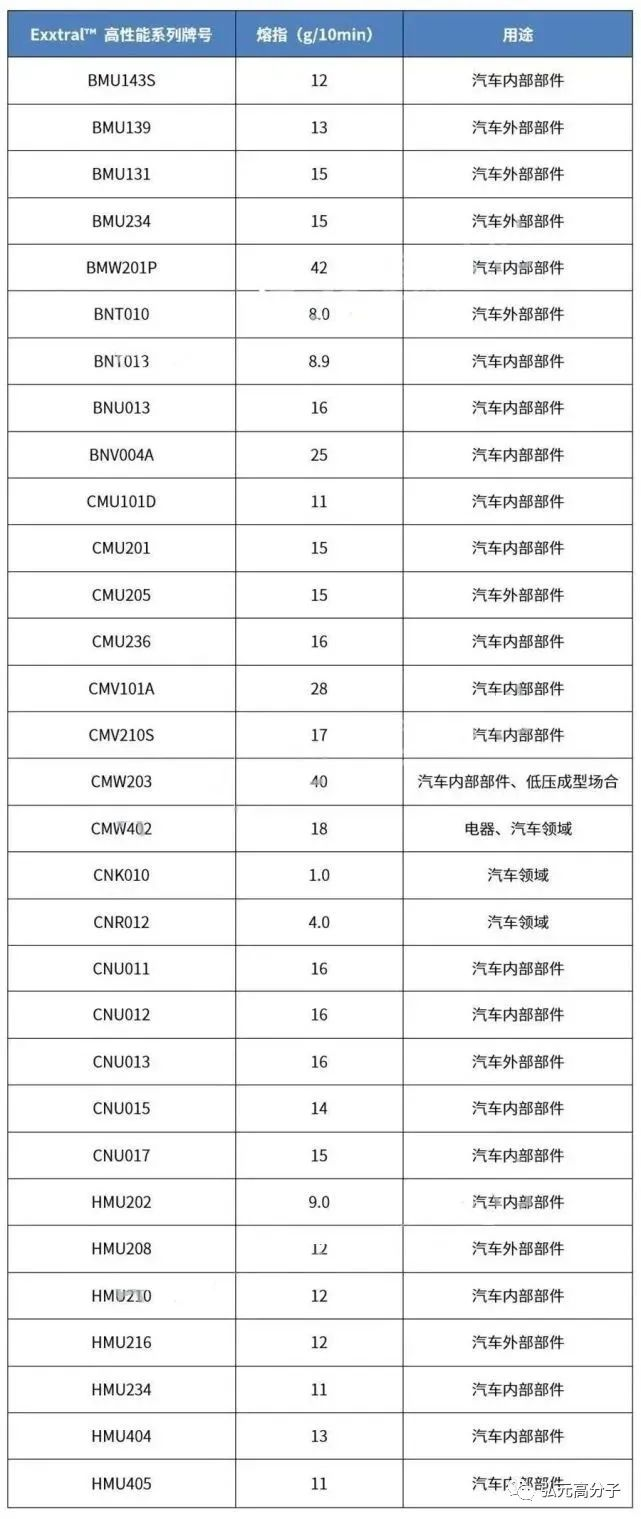

in the Global Polypropylene Market, which killer are the old polypropylene giants holding? exxonMobil is one of the world's major polypropylene producers. The main series of polypropylene products include AchieveTM high-end polypropylene, ExxonMobilTM polypropylene and ExxtralTM high-performance polypropylene.

liendbarsel is currently the second largest polypropylene producer in the world. There are 432 brands of main polypropylene products, including 6 types of polypropylene, including metallocene polypropylene, high crystalline polypropylene, random copolymer polypropylene, special polypropylene, homopolymerized polypropylene, impact resistant copolymer polypropylene, etc.

Among them, there are 8 brands of metallocene polypropylene products, 6 brands of highly crystalline polypropylene, 68 brands of random copolymer polypropylene, 17 brands of special polypropylene, 154 brands of homopolymerized polypropylene, anti-impact copolymer polypropylene 170 brands.

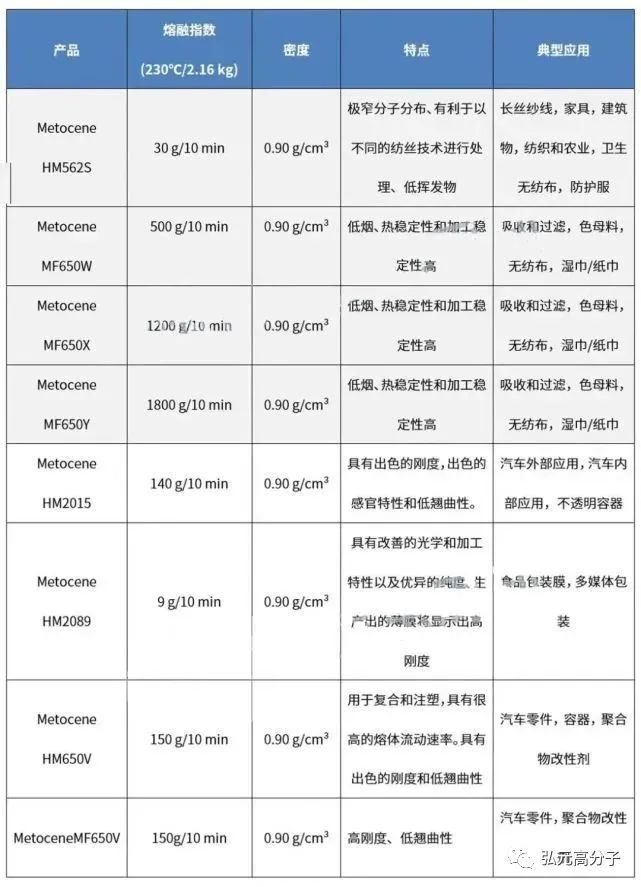

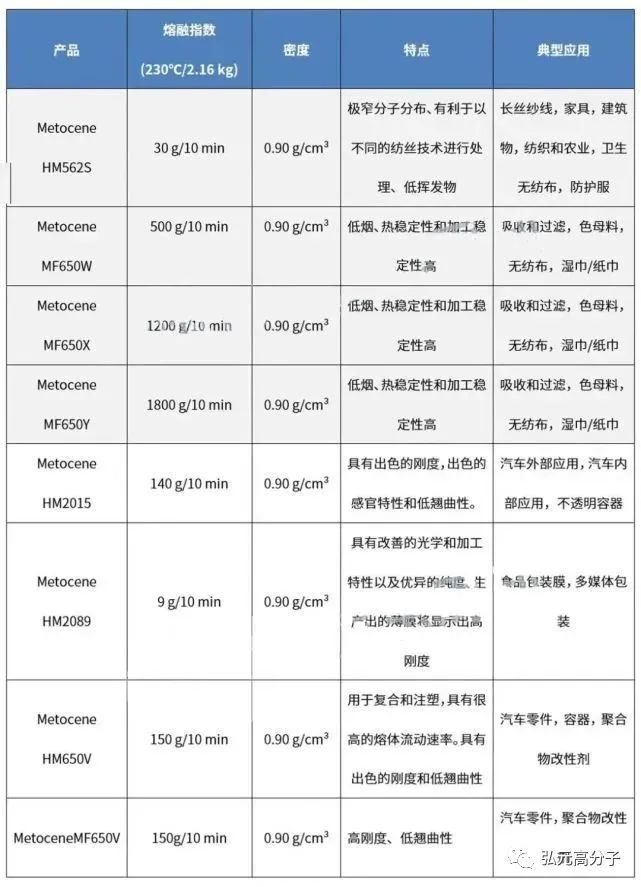

Metallocene polypropylene

liandbassel has developed 8 brands of related products, which are widely used in fiber, casting film, injection molding and composite flow modifier.

Among them, Metocene HM562S, Metocene MF650W, Metocene MF650X, Metocene MF650Y and other four brands are mainly used in non-woven fabrics and medical industry.

Metocene HM562S is mainly used in sanitary non-woven fabrics and protective clothing. Metocene, which is mainly made of Metocene MF650X and melting spray non-woven MF650Y, can be used to make medical masks and N95 masks.

The fiber diameter of the most important meltblown layer in medical masks is about 2cm, which plays a vital role in preventing bacteria and blood penetration.

The melting spray non-woven raw materials require high fluidity. The metallocene polypropylene Metocene MF650X, Metocene MF650Y developed by liandbassel company and the homogeneous polypropylene Moplen HP461Y and Moplen HP2774 mentioned below are all melting spray non-woven high-quality raw materials, in particular, melting refers to more than 1,000 related brands of polypropylene, and Lyde Bassel is in a leading position in this field in the world.

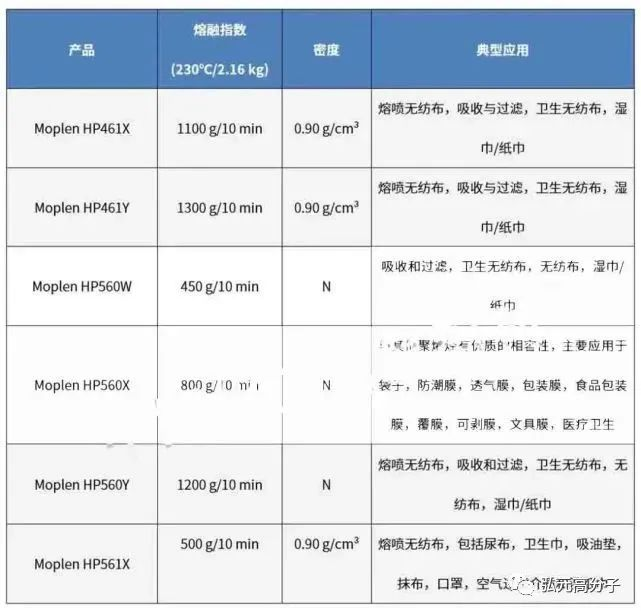

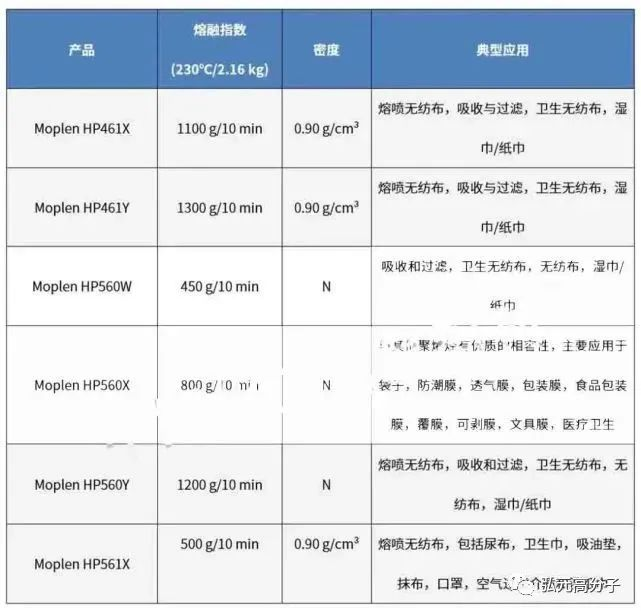

Homopolymerized polypropylene

homopolymerized polypropylene is a thermoplastic resin generated by polymerization of polypropylene and Ziegler-Natta catalyst, which can be used in different processing technologies, such as injection molding, blow molding, film, fiber, sheet extrusion and thermoforming. Liendbassel has developed 154 brands of related products, which are widely used in the market demand of packaging, daily necessities, textiles, films, medical care, pipelines and applications in the automotive and electrical industries.

It can be listed as applicable to 5 related brands of melting spray non-woven, among which Moplen HP560W brand is currently only used in Europe, Moplen HP560Y brand is currently only used in the Middle East and Europe, these two melting spray non-woven raw material brands are not currently used in the Asia-Pacific market.

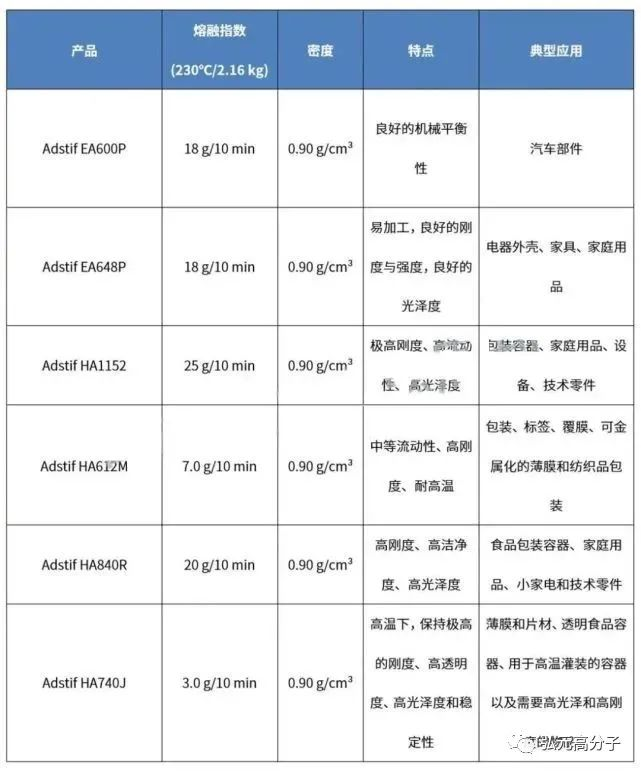

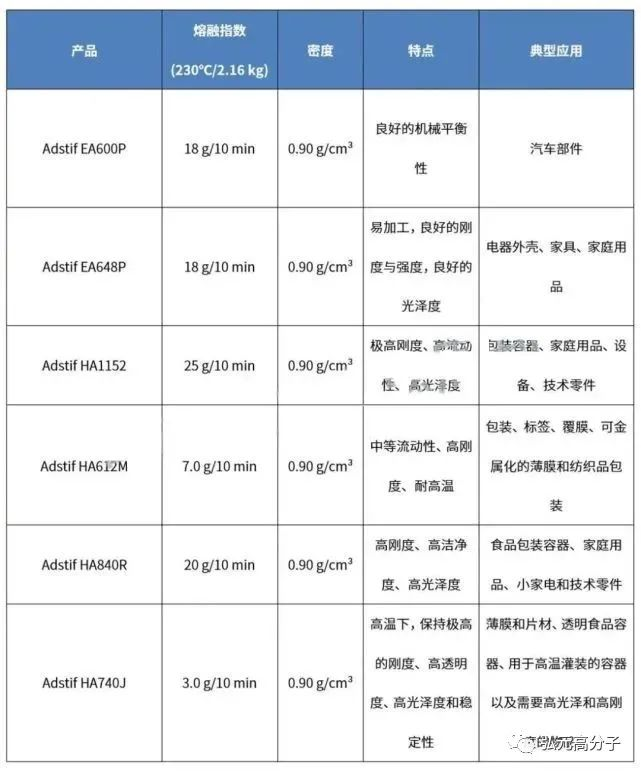

High crystalline polypropylene

polypropylene with high crystallinity is a thermoplastic resin generated by propylene polymerization, which is mainly used for thermoforming, casting film, BOPP,TWIM container and conventional injection molding.

Liandbassel has developed six brands of related products, which are widely used in the fields of automobile parts, home supplies, technical equipment, food containers, etc. The specific relevant brands in the table, among which Adstif HA612M brand is applied to the fields of labels, film coating and textile packaging due to its characteristics of fluidity and high temperature resistance.

Random copolymer polypropylene

random polypropylene is a thermoplastic resin formed by polymerization of polypropylene, in which ethylene or butene is introduced into the polymer chain. Random polypropylene has many advantages such as excellent transparency and gloss, wide melting point range, high ductility, good radiation resistance, etc.

Liendbassel has developed 68 brands of related products, which are widely used in high transparency packaging, injection molding, pipelines and other fields, and there is no non-woven fabric field for the time being.

Among them, Purell RP320M brand is more representative. Due to its low gel content, it is applied to the manufacture of soft hard packaging of bottle caps and stoppers, laboratory instruments, medical equipment and drugs.

Impact copolymer polypropylene

impact copolymer polypropylene is a thermoplastic resin produced by polymerization of Ziegler-Natta catalyst, propylene and ethylene, which can flexibly change impact copolymer by thermoplastic, blow molding, film, fiber, sheet extrusion and thermoforming. Liendbassel has developed 170 brands of related products, which are widely used in packaging, home supplies film and pipeline applications, and automotive and electrical fields.

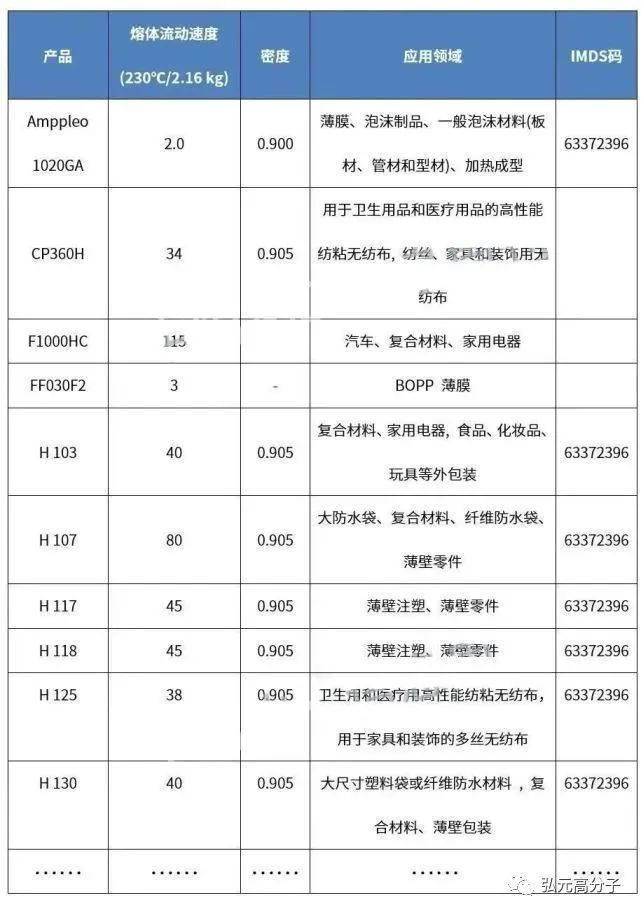

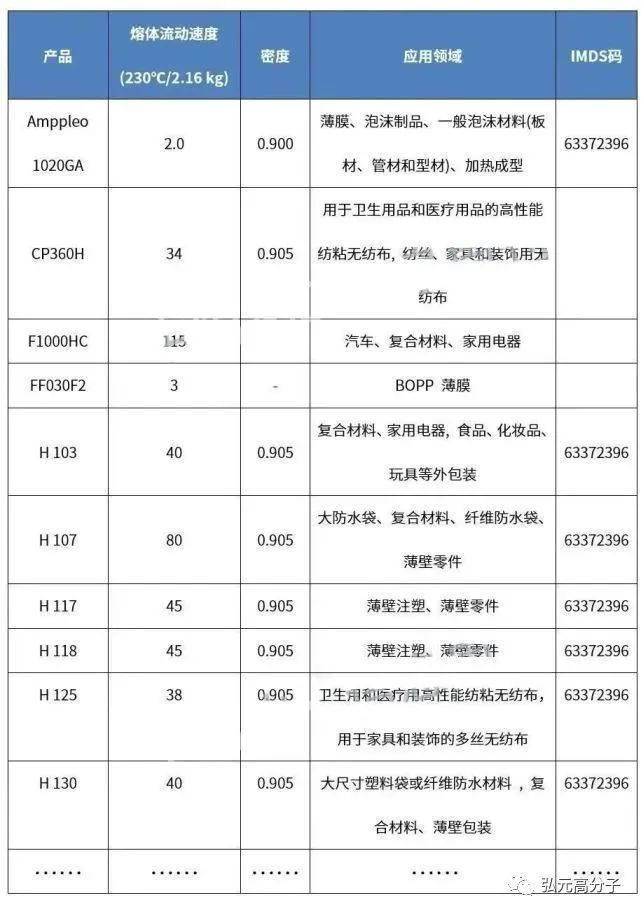

petrobras is the largest thermoplastic resin producer in America and the world's largest biopolymer producer. The plant is mainly distributed in Brazil, the United States, Mexico and Germany. Its main products are polyethylene, polypropylene and polyvinyl chloride, with customers in more than 70 countries around the world.

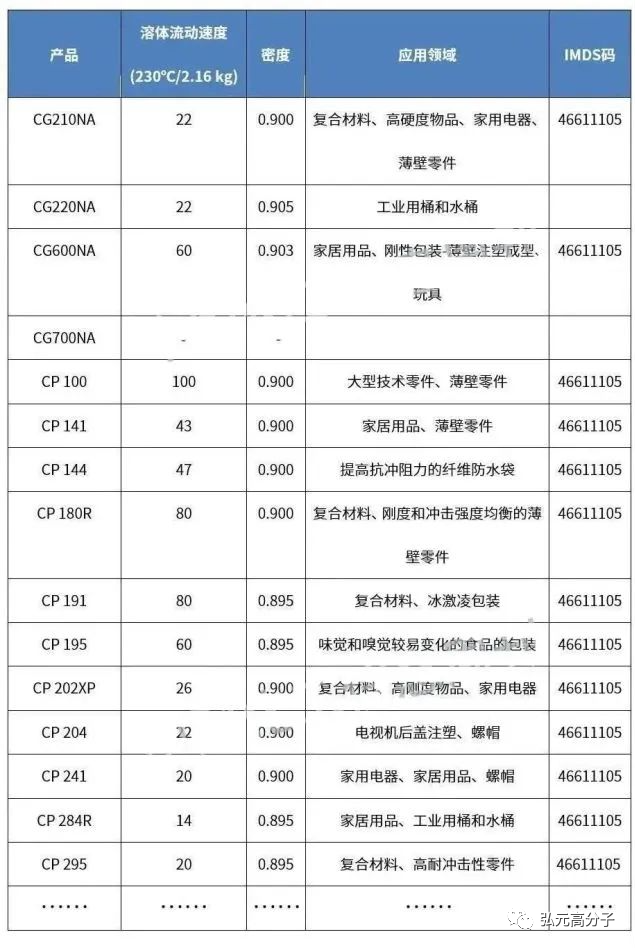

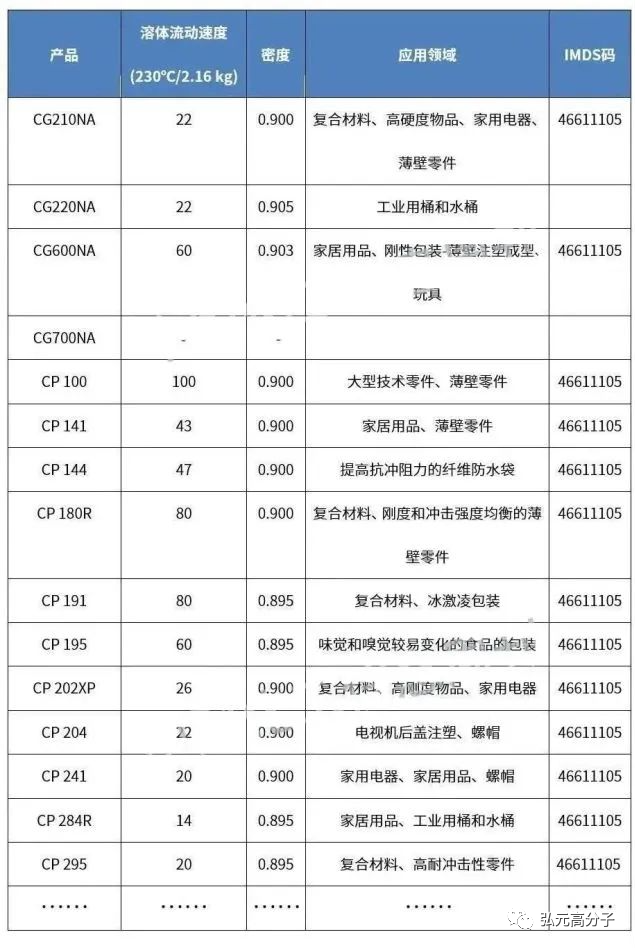

Petrobras polypropylene products include 154 brands, including 52 injection grade, 2 blown film extrusion grade, 8 cast film extrusion grade, 7 bidirectional stretching Bopp (biaxially oriented polypropylene) film, 3 bimetallic extrusion film grade, 13 fiber extrusion levels (8 fiber, 5 Raffia), 2 extrusion coating levels, 27 heating molding levels, 31 extrusion levels, 3 steel pipe coating levels, 2 blow molding levels, 4 compression molding levels.

Petrobras homopolymerized polypropylene products have higher melt flow rate and better processing performance. 44 kinds of main homopolymerized polypropylene products are widely used in automobiles, household appliances, packaging, film and medical and health fields. Among them, 7 kinds of products have become the best choice for producing non-woven fabrics, especially high-performance spunbond non-woven fabrics for medical and health use due to their good processing performance and barrier performance, product property indicators and application fields are shown below.

Impact copolymer polypropylene

petrobras impact copolymer polypropylene has good impact strength, rigidity and processability, and its hardness is generally high, which is more suitable for producing high hardness articles.

34 kinds of main impact-resistant polypropylene copolymer are widely used in the fields of toys, household goods, industrial supplies, coating and technical parts. The product properties and application fields are as follows.

Random copolymer polypropylene

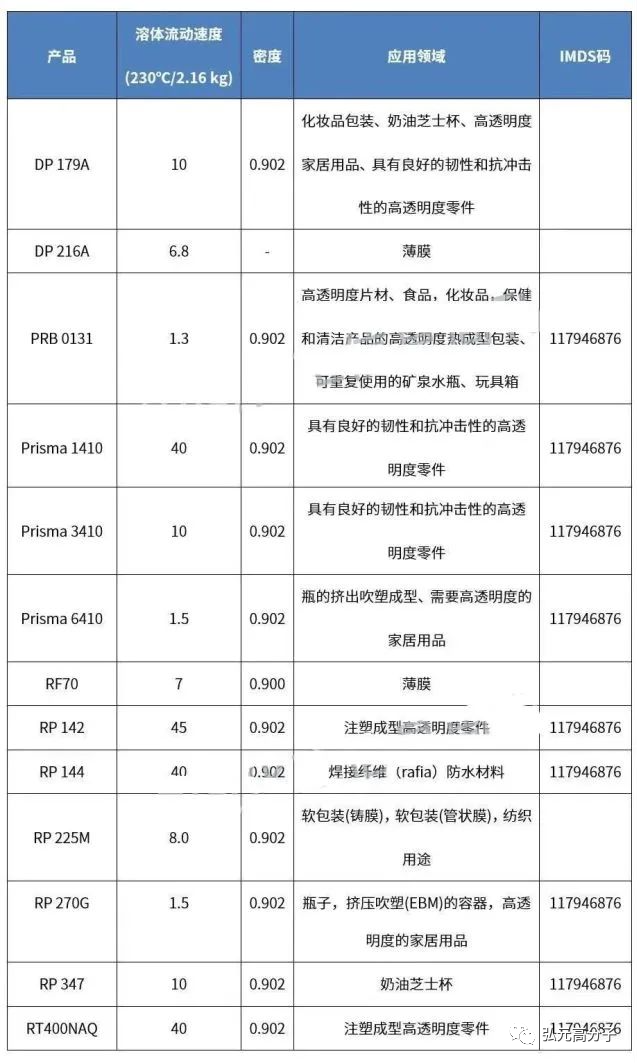

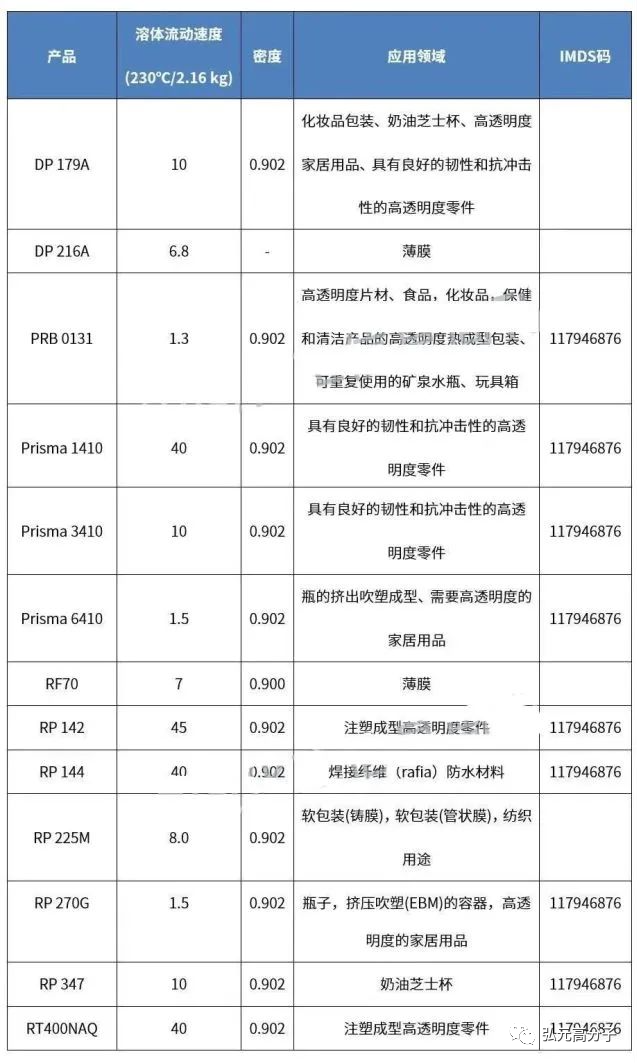

petrobras random copolymer polypropylene has excellent processing performance, low haze and high transparency, and is especially suitable for injection molding and extrusion. 13 kinds of main products are used in processing and producing high transparency parts, high transparency household products, Reusable mineral water bottles, etc. The product properties and application fields are shown in the table.

Maxio series polypropylene

petrobras has launched nine new types of Maxio series polypropylene resin, which can reduce energy consumption, improve manufacturing process productivity and reduce final product quality.

Among them, FT120WV resin is developed for CAP, plug and industrial products, which can utilize shooting technique high productivity, thus having a competitive advantage.

When Maxio PG480 is used in the field of fiber packaging, the productivity increases by 15%, while maintaining the same mechanical properties and reducing thickness fluctuation. Brazil petrochemical Maxio series polypropylene property indicators and application fields are as follows.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)