On November 2, the General Office of the Ministry of Ecology and Environment issued a notice on the issuance of the Comprehensive List of Environmental Protection (2021 Edition). The document shows that ethylene oxide and nonylphenol are high environmental risk products, and alkane (nonyl) phenol polyoxyethylene ether (APEO) is a high pollution and high environmental risk product. on

1231, Jiangsu Provincial Emergency Management Department issued an announcement that 112 hazardous chemical production enterprises (see annex) terminated their hazardous chemical production activities, including two leading nonylphenol polyoxyethylene ether enterprises-Jiangsu Lingfei Technology Co., Ltd., Jiangsu Jiafeng Chemical Co., Ltd.

According to the Surfactant Development Center, the output of alkylphenol polyoxyethylene ether in China will be about 69,000 tons in 2020, accounting for about 5.4% of the total output of non-ionic surface activity. Alkylphenol polyoxyethylene ether to OPEO (OP), NPEO (NP) and TX as the main products, due to environmental protection policies continue to tighten and other reasons, in recent years, NP (mainly NP-10) consumption gradually reduced, of which the textile printing and dyeing industry demand decline is the most significant.

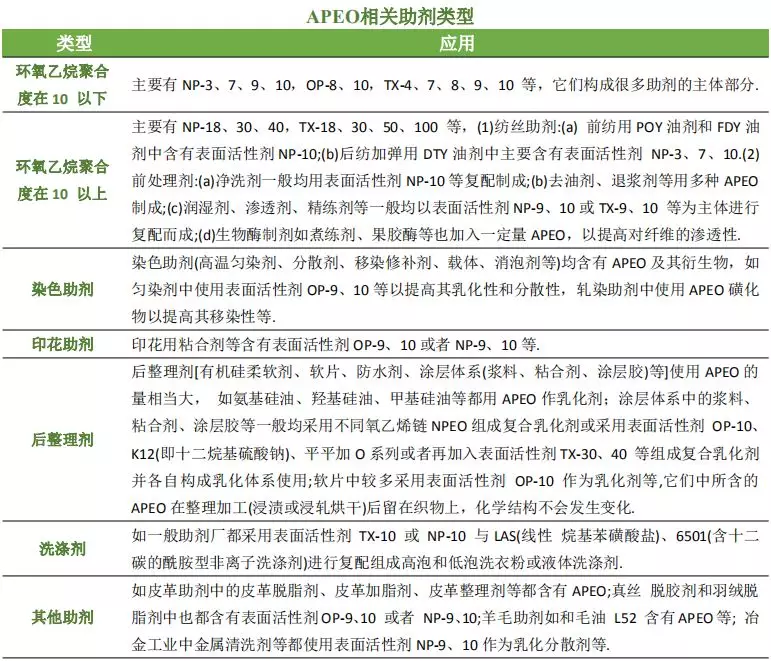

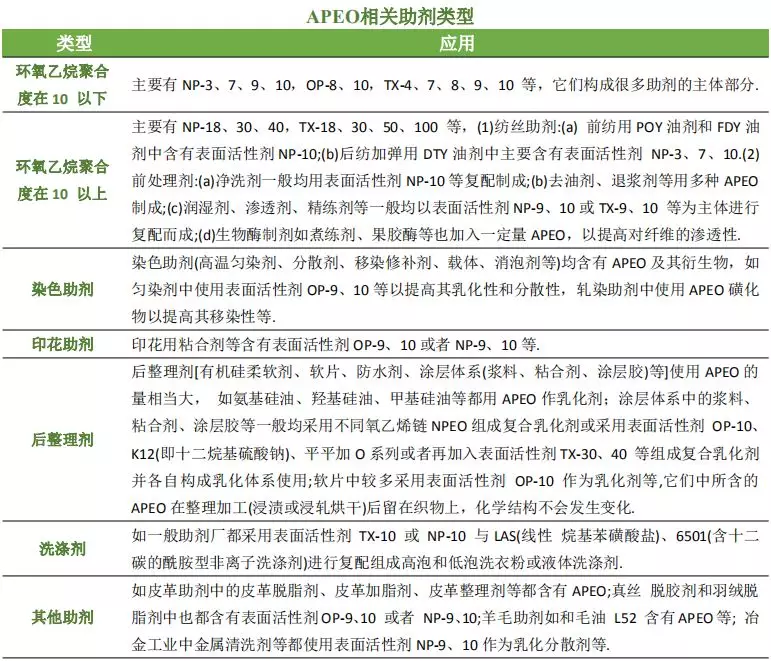

APEO has excellent penetration, emulsification, dispersion, infiltration and washing functions. It has been widely used in daily chemical, papermaking, metallurgy, textile, petroleum and personal care products industries. It is mainly used in the textile industry. Detergents, coating finishing agents, refining agents, adhesives, and various textile finishing aids and oil agents in the production process.

Alkylphenol polyoxyethylene ether (APEO) is a polyoxyethylene nonionic surfactant.

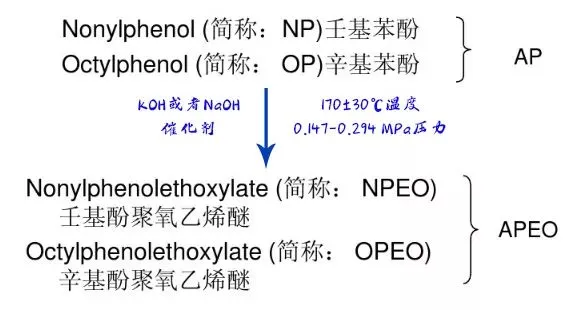

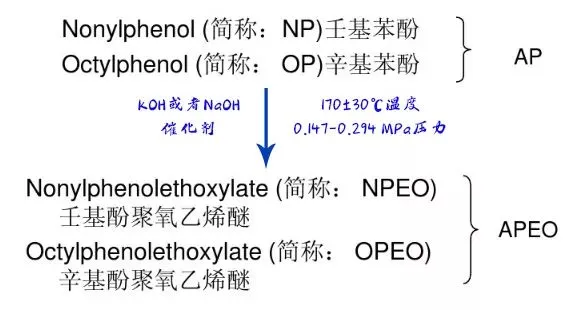

APEO is prepared by polymerizing alkylphenol (AP), mainly nonylphenol (NP) and octylphenol (OP), with KOH or NaOH as catalyst according to a certain proportion, at a temperature of 170±30 ℃ and a pressure of 0.147-0.294 MPa, a series of mixtures with different polymerization degrees are generated. APEO after polymerization mainly includes nonylphenol polyoxyethylene ether (NPEO) and octylphenol polyoxyethylene ether (OPEO), of which NPEO accounts for 80%-85% and OPEO accounts for more than 15%.

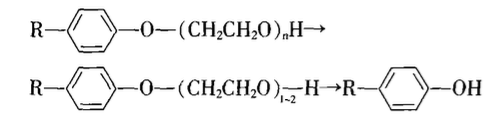

APEO has an amphiphilic structure, the hydrophobic group is a benzene ring and its attached carbon chain, and the hydrophilic group is an epoxy vinyl group.

Why do you want to disable APEO?

APEO's ecological impact can be summarized into the following four aspects: toxicity, biodegradability, environmental hormones, and production of harmful by-products. alkylphenol AP is a kind of imitation estrogen and is also known endocrine interferon. The EU restricts the use of nonylphenol (NP) due to its "toxicity, persistence and bioaccumulation". alkyl phenol polyoxyethylene ether itself is not carcinogenic and mutable, but when added with ethylene oxide, due to excessive accumulation of unreacted ethylene oxide, the oligo-ethylene and dipolyoxyethylene ring structure is 1, 4-dioxane. These two compounds have been confirmed as carcinogens and require the unreacted oxyethylene content to be limited to 1 mg/kg. APEO biodegrades slowly. After degradation, APEO and alkylphenol (AP) containing less ethoxy group (EO) are produced, and nonylphenol (NP) and octylphenol (OP) are produced. The metabolites NP and OP also cause harm to human body. NP, OP, NPEO and OPEO are all environmental hormone chemicals, which have similar effects to estrogen after invading the human body, namely the so-called "female effect" and reproductive aberration, and have become natural enemies of all living organisms including human beings. Which printing and dyeing auxiliaries contain APEO

APEO is almost ubiquitous in textile processing. APEO may be found in scouring agents, wetting agents, penetrating agents, enzyme preparations, printing paste, adhesives, coating agents, leveling agents, waterproofing agents, repair agents, various emulsions and dispersants commonly used in textile processing. It accounts for about 7.5% of the world's total surfactant consumption.

How to Handle Products with APEO

. Because APEO is hydrophilic, washing can greatly reduce APEO residue.

related studies have shown that adding ethanol as a desorbing agent in water can promote the desorption of OPEO. The best ratio is about 70% ethanol-aqueous solution, and the desorption rate can reach more than 90%. At this time, the treatment effect is the best. When desorption of OPEO and NPEO on fabrics, ethanol-aqueous solution of about 70% can also be used to achieve the maximum desorption rate. As the temperature increases the adsorption of OPEO on fabrics, therefore, the desorption rate is reduced.

, however, still suggests that relevant enterprises should give priority to selecting non-hazardous surfactants as substitutes. At present, there are many substitutes for APEO in the market, but considering the performance, raw material source, ease of use and economy, there are not many varieties that can be completely replaced at present. With the continuous development of scientific research and the increasing awareness of environmental protection, the relevant restrictions on APEO will be launched.

Source: China Textile Joint Inspection Quanzhou, Textile Fabric Platform * Disclaimer: The content contained in the content comes from the Internet, WeChat public number and other public channels, we maintain a neutral attitude towards the views in the article. This article is for reference only. The copyright of the reprinted manuscript belongs to the original author and organization. If there is infringement, please contact Huayi Tianxia Customer Service to delete the.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)