Acrylic is polymethyl methacrylate (polymethyl methacrylate), referred to as PMMA it is a kind of polymer made of methyl methacrylate, also known as organic glass. It has the advantages of high transparency, high weather resistance, high hardness, easy processing and molding, and is a frequently used glass substitute material.

The relative molecular mass of PMMA is about 2 million, and the chain forming molecules is relatively soft, so the strength of PMMA is relatively high, and the tensile and impact resistance ability is 7~18 times higher than that of ordinary glass. When it is used as organic glass, even if it is broken, it will not produce burst fragments like ordinary glass.

PMMA is the transparent polymer material with the best optical performance at present, and its light transmittance reaches 92%., higher light transmittance than glass and PC, which has become the most important basic characteristic of many applications.

The weather resistance of PMMA is also second to none in commonly used plastics. Under SAE J2527, the weather resistance test of automobile exterior decoration can meet the weather resistance test of 3500-4000 KJ/m2, which is much higher than that of ordinary PC, PA and other plastics. In addition, the pencil hardness of PMMA can reach 2H, which is much higher than other common plastics such as PC, and has good surface scratch resistance. PMMA has been widely used in automobile, electronics and household appliances, consumer goods, lighting, architecture and building materials, medical treatment and other fields due to its excellent characteristics.

Application of PMMA in automobile field

in general, PMMA is used in automobile taillights, dashboard masks, external columns and decorative parts, interior light, rearview mirror Shell and other fields, mainly in areas such as transparency, translucency and high gloss.

car lights are divided into headlights and taillights, and parts such as lampshades need to use transparent materials. Headlight and fog lamp shade mostly use polycarbonate PC materials, because the headlights are often used for a long time during driving, and the impact resistance of the lampshade is relatively high when the car is driving. However, PC used in headlights also has the disadvantages of complicated process, high cost and easy aging.

Taillights are generally turn signals, stop lamp, etc., with low light intensity and short service time, so they have relatively low heat resistance requirements. PMMA materials are mostly used, and PMMA transmittance is 92%, higher than 90% of PC, refractive index 1.492, good weather resistance and high surface hardness, is an ideal material for taillight mask, reflector and light guide. Due to the high hardness, PMMA has good scratch resistance, and can be used directly without surface protection when it is used as an external light distribution mirror material. However, light scattering PMMA has high scattering characteristics and is easy to achieve uniform lighting effect, which is one of the key materials currently used in taillights. dashboard mask mainly protects instrument and accurately display instrument data. Dashboard cover is generally injection molding. PMMA is widely used, with high transparency, sufficient strength and rigidity, good dimensional stability, and no deformation under the high temperature of solar radiation and engine waste heat, under long-term high temperature, it will not deform, fail, and will not affect the accuracy of each instrument.

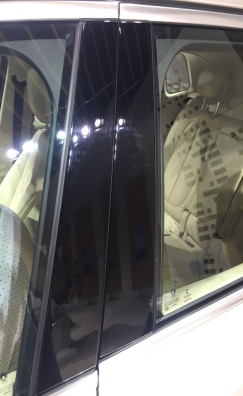

Outer column and decorative parts

the outer column of the automobile is divided into ABC columns, whose performance requirements are mainly high gloss (usually piano black), High weather resistance, high heat resistance and scratch resistance. The common solutions are ABS + spray paint, PP + spray paint, PMMA + ABS double-layer extrusion scheme, and toughened PMMA scheme. Compared with the painting scheme, PMMA can avoid the spraying process, is more environmentally friendly and has lower cost, and gradually becomes the mainstream scheme.

interior light includes reading lights and ambience light. Reading lights are part of the interior lighting system of automobiles and are usually installed on the front roof or rear roof. In order to prevent light pollution, reading lamps generally need to scatter light, and matte or frosted PMMA or PC schemes can be used. Ambience light is a decorative lighting lamp that can create a comfortable atmosphere and improve the texture of the whole vehicle. Ambience light the light-guide strip used can be divided into soft and hard according to its texture. Hard Light-guide strip is hard and cannot be bent. It is usually molded by injection molding or extrusion. The material is mainly PMMA, PC and other transparent materials.

PMMA for rearview mirror shell

rearview mirror shell mainly requires high gloss and black brightness, as well as high impact strength, scratch resistance and weather resistance. Because the shape of shell mirror is generally curved surface, it is easy to generate stress, so it requires high processing performance and toughness. The conventional scheme has ABS spray paint, but the process pollution is serious and there are many processes. The PMMA scheme can realize no spraying. Generally, the toughened PMMA material should be adopted here, to meet the drop experiment and other projects in its testing schedule.

The above is the conventional application of PMMA in the automotive field, which is mainly related to optics or appearance. PMMA adds more possibilities to the automotive field.

* Disclaimer: the content contained is from public channels such as the Internet and WeChat public accounts. We maintain a neutral attitude towards the views in this article. This article is for reference and communication only. The copyright of the reprinted manuscript belongs to the original author and organization. If there is any infringement, please contact Huanyi world customer service to delete it. Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)