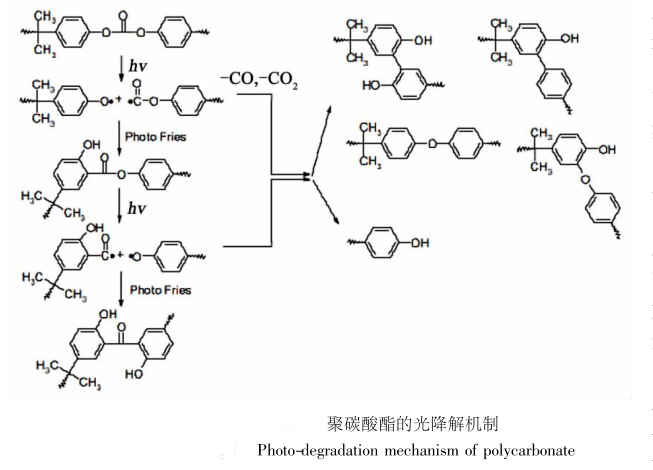

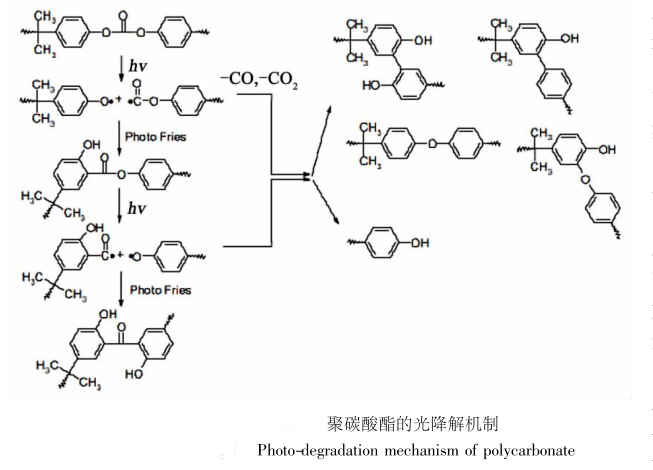

Polycarbonate (PC) is a thermoplastic polymer material with the advantages of high impact resistance, high light transmission and high heat-proof. However, under long-term sunlight exposure, ultraviolet light will be absorbed and photodegradation will occur. Rivaton et al. used Fourier transform infrared spectroscopy (Fourier transform infrared spectroscopy) and ultraviolet (UV) to conduct photoaging tests, and proposed the degradation mechanism of polycarbonate (as shown in the following figure). However, studies such as Andrady show that Photo-Fries rearrangement will occur when polycarbonate irradiates ultraviolet light, resulting in the generation of yellow substances, thus affecting the appearance of polycarbonate products.

There are three types of additives commonly used in PC: one is the high temperature processing protection additive antioxidant, antioxidant is divided into hindered phenolic main antioxidant and phosphite auxiliary antioxidant due to its different protection principles; The second is the lubricant for material processing and molding, stearic acid lubricants are commonly used; The third category is toner for color adjustment, and organic pigments are commonly used. Analysis of the effect of antioxidant additives on PC yellowing

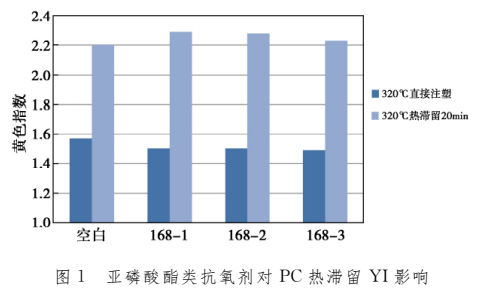

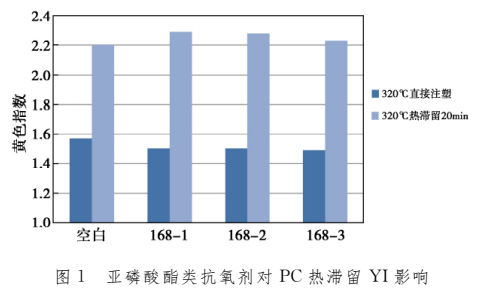

1. Effect of phosphite antioxidant on PC yellowing

add 168 PCs from different manufacturers and blank PCs before and after heat retention in injection molding machine, see figure 1.

As can be seen from Figure 1, after 168 from different manufacturers are added, the yellow Index (YI) value of direct injection molding samples has a certain range of reduction, indicating 168 has a protective effect on the color of materials during processing. After 20min heat retention, adding phosphite antioxidant, the yellow index of PC is higher than that of blank PC, the possible reason is that the trivalent phosphorus of phosphite antioxidant is gradually consumed into pentavalent phosphorus during high temperature and loses its antioxidant capacity. On the contrary, small molecules and impurities in antioxidant further affect the decomposition of PC at high temperature, the YI value of PC is higher than that of blank sample after heat retention at 320℃ for 20min.

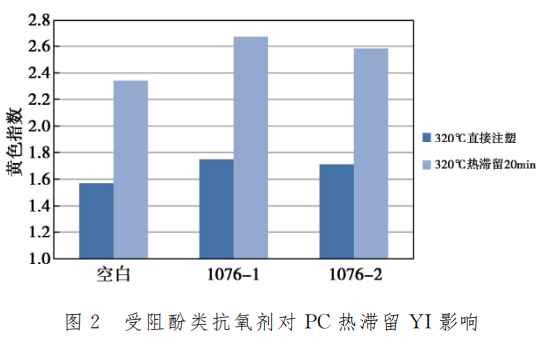

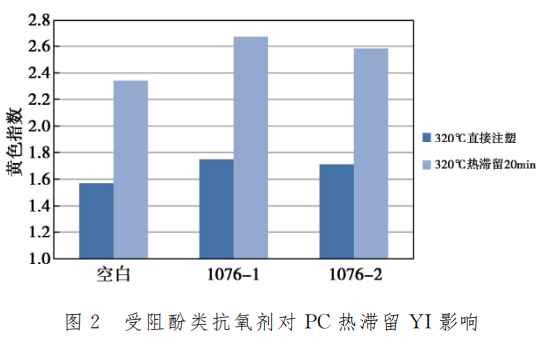

2. Effect of hindered phenolic antioxidant on PC yellowing

add 1076 PCs from different manufacturers and blank PCs before and after heat retention in injection molding machine, see figure 2.

As can be seen from the smalt bar chart in Fig. 2, the YI value of PC samples directly injected by 1076 different manufacturers is higher than that of blank PC, and the yellow index of the material is not reduced as 168. It can be seen from the red bar chart that after heat retention for 20min, the YI value of 1076 is higher than that of blank PC, and the amplitude is higher than that before heat retention, this shows that the main antioxidant, as a long-acting antioxidant, will not effectively protect the high-temperature processing process like phosphite antioxidant in the high-temperature processing process, and due to the influence of hindered phenol structure, although the phenolic oxygen radical generated after hydrogen loss of hindered phenol is relatively stable, it may produce wake-up chromophoric groups in high temperature environment, which leads to the increase of YI and affects the optical properties of PC.

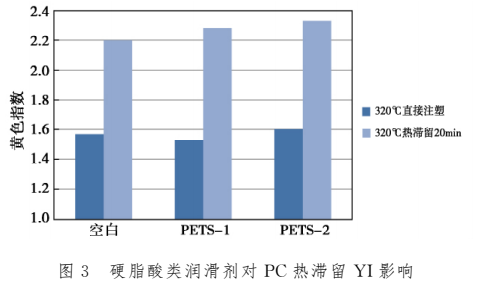

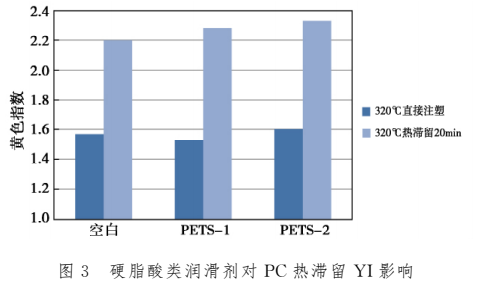

Effect of stearic acid lubricant on PC yellowing

add PCs of PETS from different manufacturers and blank PCs before and after heat retention in injection molding machine, see figure 3.

The comparison of smalt bar chart in Fig. 3 shows that there is no obvious difference in YI value between blank PC and PC added lubricant after direct injection molding. After heat retention, YI value increases slightly, but the influence is limited. The possible reason is that there is a very small amount of pentaerythritol or stearic acid residue in the lubricant, which will cause PC to produce alcoholysis and transesterification reaction under a long period of high temperature, accelerate the aging of PC, resulting in an increase in yellowing.

Influence of toner on PC yellowing

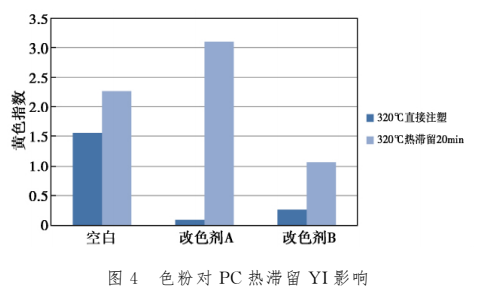

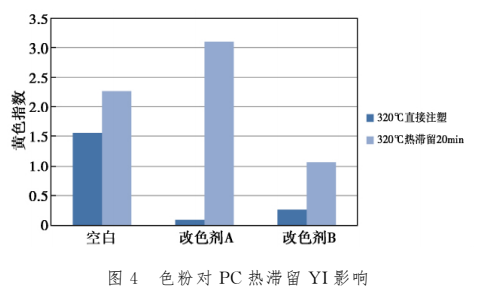

the color changes of PC and blank PC added with different kinds of toner before and after heat retention in injection molding machine are shown in figure 4.

As can be seen from Figure 4, adding two kinds of toner in the same amount can greatly reduce the YI value of PC however, after heat retention at 320℃ for 20min, the color difference of toner A rebounded greatly, while the change range of Toner B is equivalent to that of blank particles, this shows that there are great differences between the application effect of different kinds of toner under short-time high-temperature processing and long-time high-temperature stay, which may lead to serious discoloration of PC high-temperature processing.

Analysis of heat resistance of toner

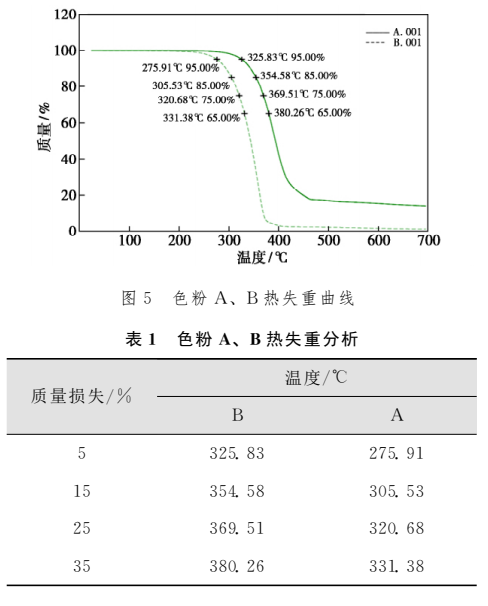

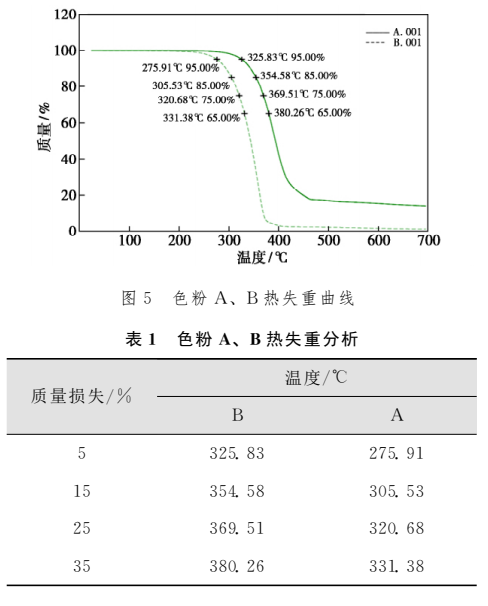

the color powder A and color powder B were tested by TGA respectively. Under nitrogen atmosphere, the heating rate of 10 ℃ / min rose to 700 ℃. The difference of heat resistance between the two is shown in figure 5. The temperatures corresponding to the four points of weightlessness of 5%, 15%, 25% and 35% of the two toner in Fig. 5 are shown in Table 1.

Through the curve of figure 5, it can be found that the thermal stability of the two toner is quite different., the initial thermal decomposition temperature of Toner B is about 325℃, while the initial decomposition temperature of toner A is only 275℃. During The weightlessness process, Toner B is about 50℃ higher than Toner A.

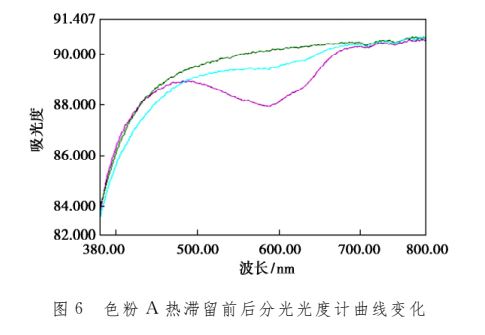

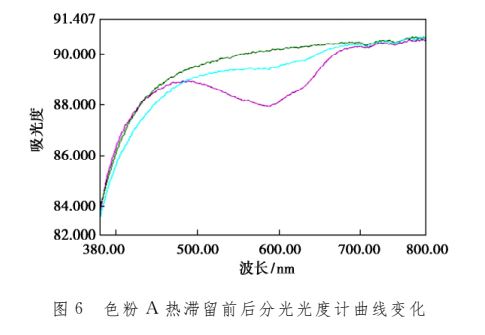

Under 600nm wavelength, the comparative analysis of the spectrophotometer curve between the sample before and after the heat retention of PC added Toner A and the blank PC is carried out, and the obtained results are shown in figure 6. The three curves in the figure are blank PC curve, PC heat retention curve after adding toner A, and PC heat retention curve before adding toner A respectively from top to bottom.

As can be seen from Fig. 6, Toner A has obvious absorption peaks at 450 ~ 700nm, while after 20min of heat retention, the absorption peaks are obviously weakened, indicating that the chromophoric groups of some Toner A have changed, the PC is severely discolored.

Yellowing analysis of adding various additives to PC

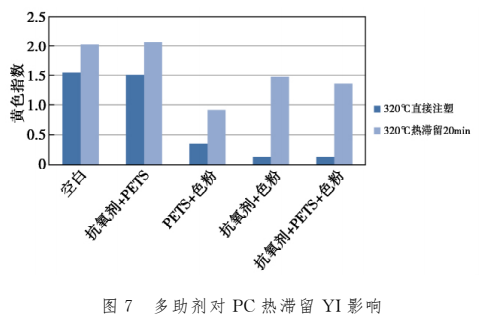

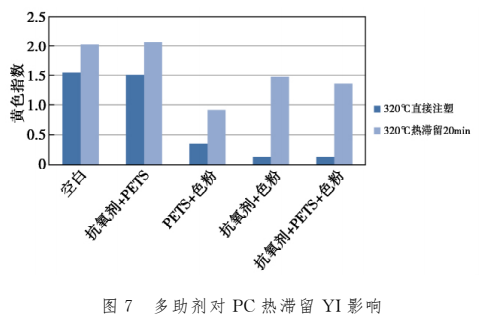

using 168, PETS and Toner B to carry out further analysis, the heat retention injection molding experiment was carried out with PC after mixing antioxidant, lubricant and toner in two pairs or three, and the obtained results are shown in Figure 7.

As can be seen from the first two bars in figure 7, the YI values of PC added with antioxidant and PETS are basically the same as those of blank PC, and there is no obvious difference. The two have little effect on the yellowing of high-temperature processing of materials, this result is consistent with the result of adding two additives separately.

The color difference between PC and blank before and after heat retention of toner and PETS is not much different, indicating that PETS and Toner will not affect each other and have little effect on PC yellowing.

As can be seen from the last two bar charts in figure 7, after the combination of antioxidant + Toner and the three, the PC has yellowing and increasing, indicating that antioxidant has mutual influence with toner, the possible reason is that antioxidant itself or its high-temperature decomposition products react with toner, affecting the chromophore of toner.

* Disclaimer: the content contained is from public channels such as the Internet and WeChat public accounts. We maintain a neutral attitude towards the views in this article. This article is for reference and communication only. The copyright of the reprinted manuscript belongs to the original author and organization. If there is any infringement, please contact Huanyi world customer service to delete it. Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)