foaming materials, also known as "foaming agents", or foaming substances, refer to foaming substances that can generate bubbles when substances can not vaporize, making them into empty substances, such as foamed plastics, foamed rubber, foamed resins, foamed foods, etc. Due to its wide range of uses, the market size is currently growing at a 20% rate every year. Pingtou elder brother believes that in the field of related new materials, the market growth rate of foaming materials is currently a fast-growing industry in the application field of new materials, and it has also aroused great attention from the industry.

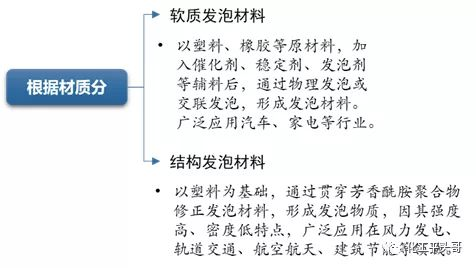

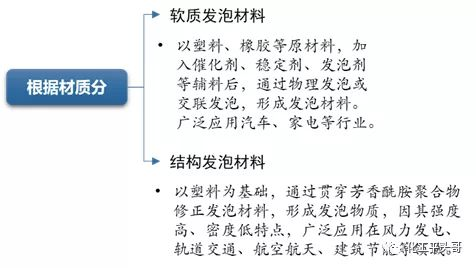

Figure 1 Foam Material Classification

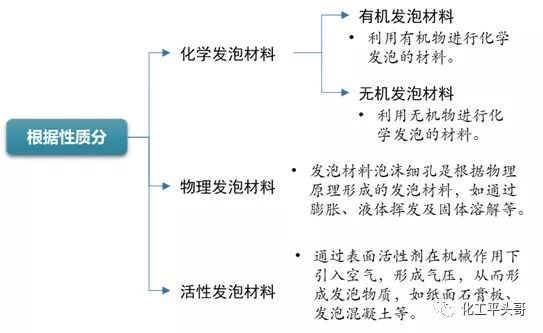

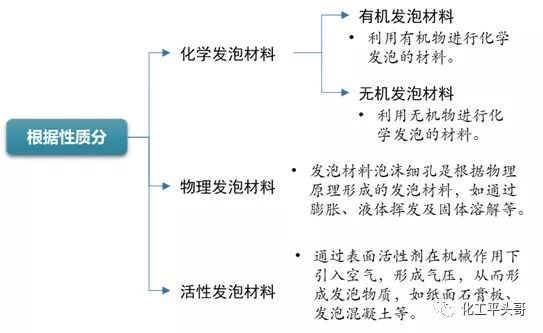

Figure 2 Classification of Foam Materials by Properties

everyone mentioned foaming materials, the first thing that comes to mind is polyurethane foaming materials, because polyurethane foaming materials are the products with the largest proportion of foaming materials in China in terms of application scope and scale.

polyurethane foaming materials are mainly divided into soft PU foam, hard PU foam and spray foam. Flexible PU foam is used for various applications, such as cushioning, clothing filling and filtration, while hard PU foam is mainly used for thermal insulation boards and laminated insulation materials in commercial and residential buildings, as well as (spray) foam roofs. The main component of

polyurethane foam (PU foam) is polyurethane, and the raw materials are mainly polyisocyanate and polyol. By adding appropriate additives, a large amount of foam is generated in the reaction product, thus obtaining polyurethane foam products. Polyurethane foam plastic is generally only used for high-grade precision instruments, valuable equipment, high-grade handicrafts and other cushioning packaging or cushion materials, can also be made into delicate, excellent protective packaging containers; also can be used on-site foaming of articles for cushioning packaging.

Figure 3 Main Applications of Polyurethane Foaming Materials

Polyurethane foaming materials can be divided into: polyisocyanates, polyether polyols, polyester polyols, polymer polyols, polyurea polyols, of which different types, downstream applications are also different.

polyisocyanates: toluene diisocyanate (TDI), polymethylene polyphenyl isocyanate (PAPI), diphenylmethane diisocyanate (MDI) and liquefied MDI (L-MDI), etc., can be used to produce high resilience soft foam, whole skin foam, semi-rigid foam, high resilience foam.

polyether polyols: polyether polyols used to produce polyurethane soft bubbles are generally long-chain, low-functionality polyethers. High-activity polyethers are mainly used for high-resilience soft bubbles, and can also be used for foam products such as semi-rigid bubbles.

polyester polyol: low viscosity aliphatic polyester polyol, such as polyadipate diethylene glycol with a hydroxyl value of about 56mg KOH/g, can be used to make polyester polyurethane soft foam.

polymer polyol: contains rigid styrene, acrylonitrile homopolymers and copolymers and graft polymers. These vinyl polymers act like organic "fillers" and improve load-bearing properties. It can be used to produce high hardness soft block foam, high resilience foam, hot molded soft foam, semi-rigid foam, self-skinning foam, reaction injection molding (RIM) products, etc.

polyurea polyol: It is also a special polymer modified polyol, which can be used for high resilience soft foam, semi-rigid foam and soft foam. There are few products on the market at present.

According to the scale of the industry, the market scale of polyurethane foaming materials accounts for the largest proportion, with a market scale of about 4.67 million tons, of which soft foam polyurethane foaming materials are the main materials, accounting for about 56%. With the vigorous development of China's electronic and electrical fields, especially the improvement of refrigerators and construction applications, the market scale of polyurethane foam materials continues to grow.

flat brother saw that besides polyurethane foaming materials, common foaming materials include EPS foaming materials, EVA foaming materials, PE and PP foaming materials, etc.

EPS foaming material: it is a light polymer. It uses polystyrene resin to add foaming agent, and at the same time it is heated to soften to generate gas to form a rigid closed-cell foam.

Figure 4 EPS Foaming Material

EVA Foaming Material: zhuan Foaming Material Made of EVA and Low Density Polyethylene Bainene as Raw Materials, Adding du to Other Zhiyi Agents and After Molding Foaming Dao or Injection Foaming. With excellent chemical properties, it is widely used in the manufacture of shoe materials, luggage lining, toy materials, sporting goods materials, building materials, and various emerging applications such as electronic accessories and automotive interiors.

Figure 5 EVA foam material

PE and PP foam material: PE or PP material foaming, generally using its excellent cushioning characteristics, heat insulation performance, toughness, etc., excellent resistance to chemical corrosion and processability, and low cost. It is widely used in machine cushioning materials, instruments, glassware, food cushioning pads, etc.

Figure 6 PE Foaming Material

Pingtou Ge Statistics, the global foaming material market is about US $93.9 billion, growing at a rate of 4%-5% per year. It is estimated that by 2026, the global foaming material market is expected to grow to US $118.9 billion. Among them, the key to driving the rapid development of foaming materials lies in the increasing demand for foaming materials in developing countries, mainly the increase in investment in infrastructure, new housing projects and non-residential building renovation in China, Brazil, India and other countries. It is expected that China's foaming materials will continue to show a rapid growth trend in the future.

This article is reprinted from the chemical company, the copyright belongs to the original author. Some articles failed to contact the original author in time when they were pushed. If copyright issues are involved, please contact us. We will delete the articles as soon as possible and negotiate copyright issues with you.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)