On May 30, Sinopec Ningbo Zhenhai Refining and Chemical Co., Ltd. carried out environmental impact assessment acceptance publicity for the high-end synthetic new material project.

The project has a total investment of 11.332 billion yuan, and the site is located in the central part of Ningbo Petrochemical Economic and Technological Development Zone and the north side of Yongzhou expressway. The project relies on the raw material advantages of Zhenhai Refining and Chemical production base, the construction includes 40/180,000 tons acrylic nitrile/methionine integrated unit, 65/240,000 tons/year phenol acetone/bisphenol A integrated unit, 300,000 tons/year CHPPO plant, 200,000 tons/year, isononyl alcohol units and other 4 sets of production units and supporting public and auxiliary facilities.

Basic information of the project

project name: high-end synthetic new material project construction Unit: sinopec Ningbo Zhenhai Refining & Chemical Co., Ltd. Construction site: ningbo Petrochemical Economic and Technological Development Zone project content: ben the total investment of the project is 11.332 billion yuan., the site is located in the central part of Ningbo Petrochemical Economic and Technological Development Zone and the north side of Yongzhou expressway, with a total land area of 1350 mu. Relying on the raw material advantages of Zhenhai Refining and Chemical production base, the project extends downstream with propylene as raw material. The construction includes 40/180,000 tons/acrylic nitrile/methionine integrated unit, 65/240,000 tons/year phenol acetone/bisphenol A integrated unit, 300,000 tons/year propylene oxide plant, 200,000 tons/year, isononyl alcohol units and other 4 sets of production equipment and supporting public and auxiliary facilities. Production shift system: the second operation of class four;

annual production Time: year start 8000H;

labor quota: newly added total labor quota of 395 people in the project

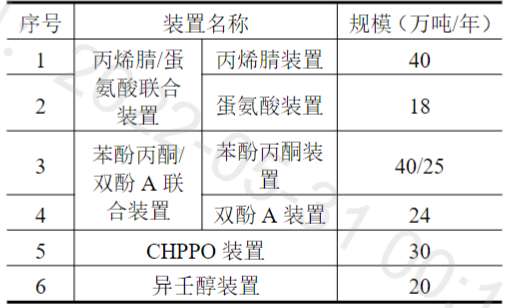

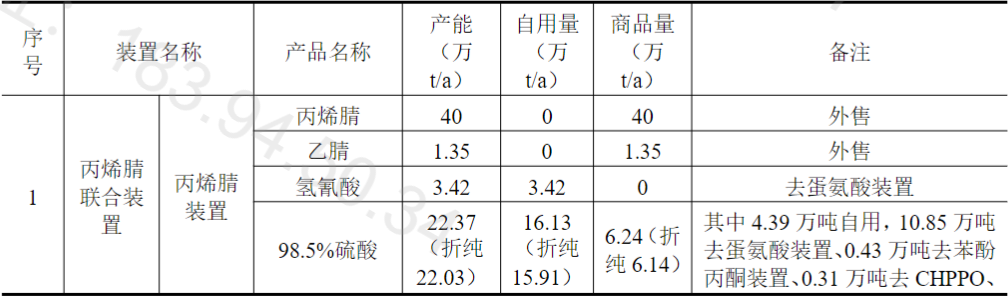

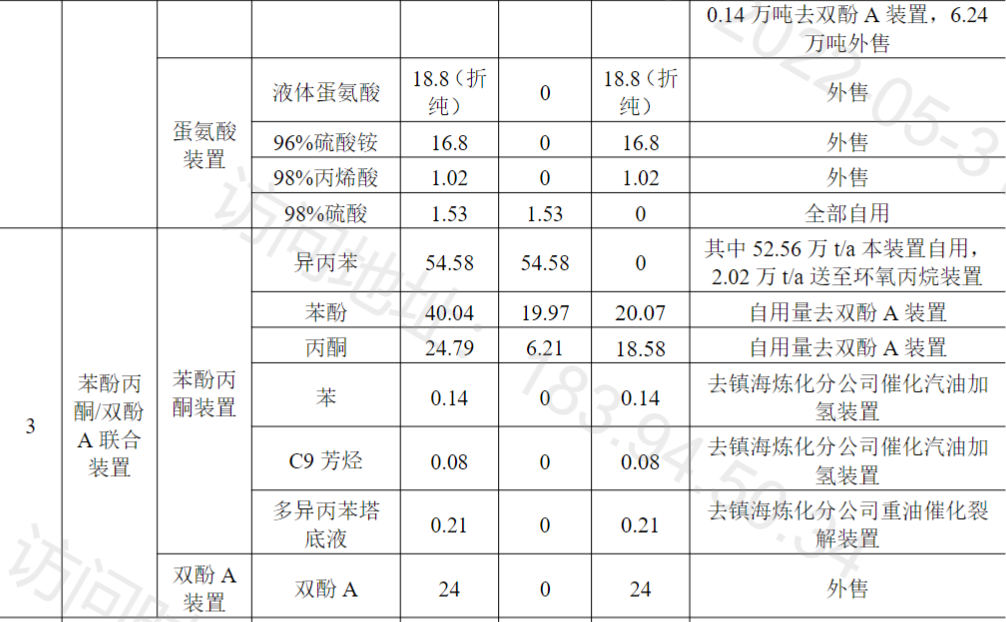

device scale and product plan

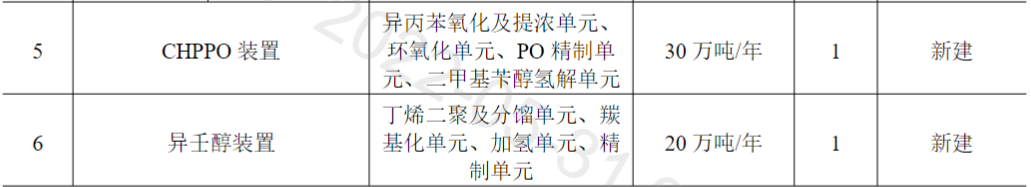

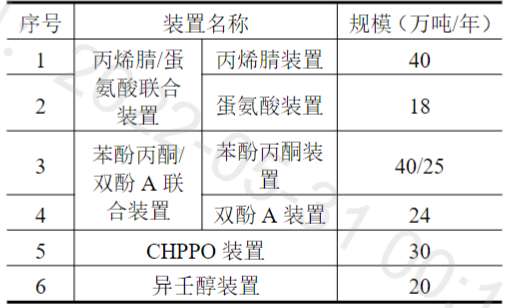

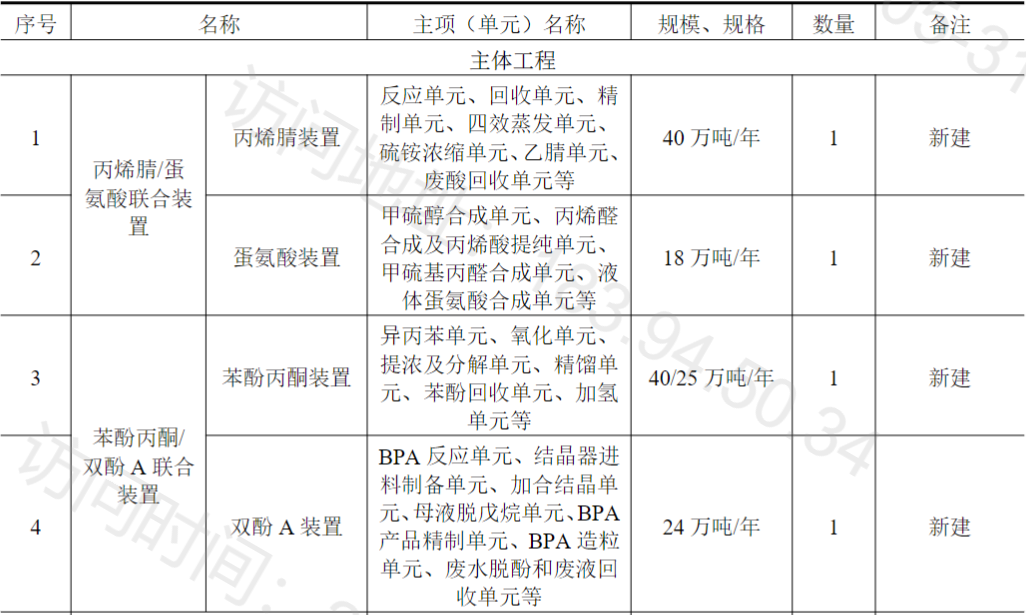

the design scale and main product scheme of each device in this project are shown in the following table.

Table production equipment and scale

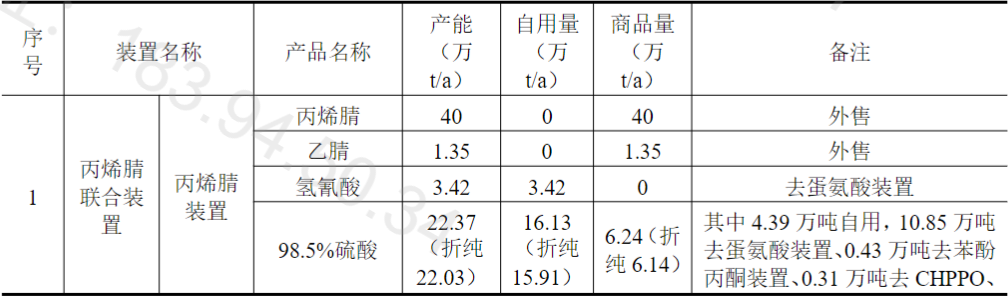

table product solution

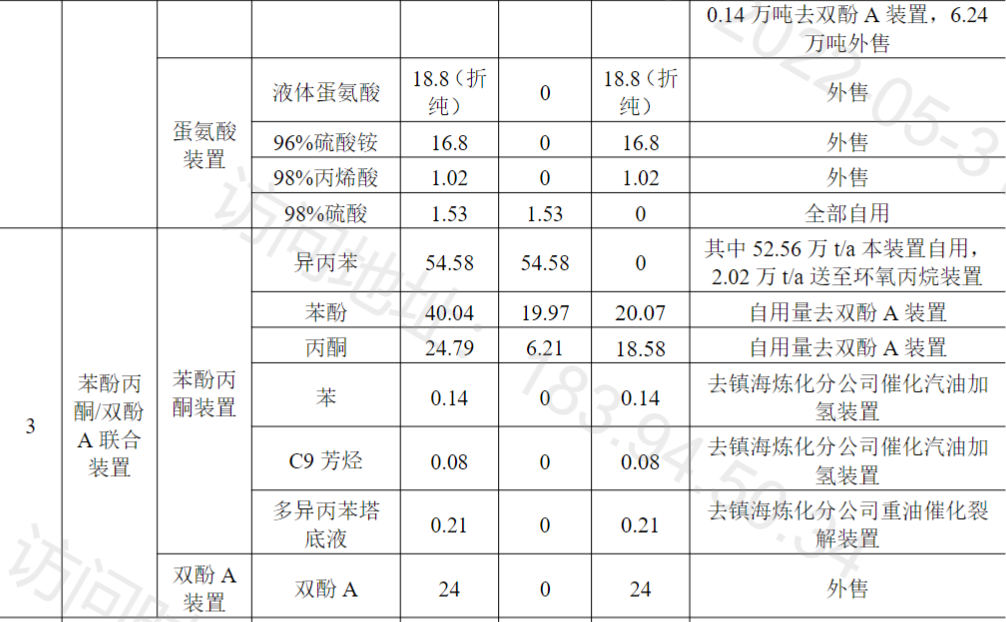

the composition of the main project of this project is shown in the following table. Table Project Main project composition

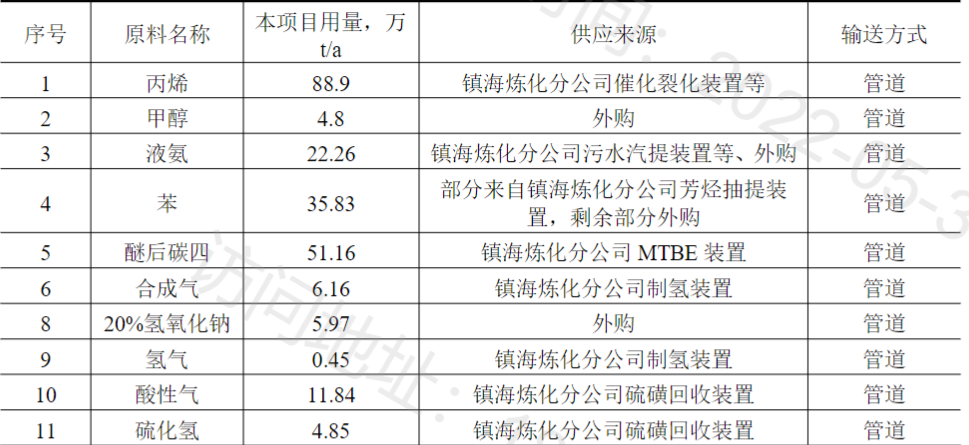

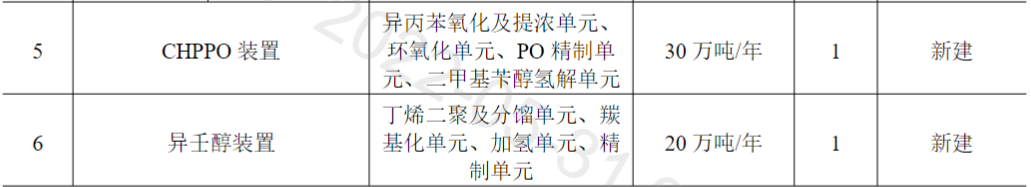

the main raw materials required by this project are supplied by Zhenhai Refining and Chemical production base, and are transported to the boundary area of this project through pipelines from the supply device product tank or direct supply. For other liquid chemicals with small consumption, the intermediate tank is set by each unit area.

Table item raw material supply table

this project is a newly-built project. The project uses propylene as raw material to extend the industrial chain downstream and give full play to the production efficiency advantages of integrated unit acrylic nitrile plant and methionine plant are used as integrated unit, acrylic Nitrile will be supplied to relevant enterprises in the petrochemical area through pipelines, and concentrated sulfuric acid and hydrocyanic acid produced by acrylic nitrile plant will be supplied to methionine plant to realize the conversion of low-value products to high-value products; Phenol acetone plant and bisphenol A plant are used as integrated unit, to realize the mutual supply between the upstream and downstream of phenol and acetone, cumene produced by phenol acetone plant is also used as the main raw material of CHPPO plant; Isononyl alcohol plant uses low-value liquefied gas and syngas as raw materials to produce isononyl alcohol products, it makes up for the market gap of regional isononyl alcohol products. The upstream and downstream devices of this project adopt direct supply of raw materials to improve production efficiency and reduce environmental risks during material export. The project adopts the combination of localization research and imported technology. The 300,000 tons/year CHPPO device adopts Sinopec's key research technology and has complete independent intellectual property rights, it is the largest direct oxidation CHPPO unit in the country; 400,000 tons/year acrylonitrile unit adopts propylene ammoxidation production technology independently developed by Sinopec; Phenol acetone, bisphenol A, isononyl alcohol and other devices have introduced the most advanced international production technology; Methionine device adopts the technology developed by Zhejiang private chemical enterprise Xincheng and Zhejiang University in cooperation.

Significance of project construction

sinopec Ningbo Zhenhai Refining & Chemical Co., Ltd. was established in June, 2018 and was jointly established by Sinopec and Ningbo. In response to the "petrochemical industry planning and layout plan" put forward "in accordance with the requirements of industrial park, refining-bulk, device scale, product high-end and management modernization, to promote the development of high-end petrochemical products, promote the adjustment and transformation and upgrading of industrial structure", Sinopec Ningbo Zhenhai Refining and Chemical Co., Ltd. plans to use the advantages of existing raw material resources in Ningbo Petrochemical District to implement high-end synthetic new material projects. Project edge the carbon three product chain develops downstream, which can open up oil refining -- propylene -- acrylic nitrile -- ABS/methionine, oil refining -- propylene -- phenol acetone -- phenol-phenol-phenol-a-polycarbonate, refining-liquefied gas-isononyl alcohol-environmental-friendly plasticizer and other characteristic industrial chains to improve the safety of the petrochemical industry chain, the coordinated development level of various industries and the overall industrial competitiveness. This project is merged with the project under construction of Zhenhai Refining and Chemical Company of Sinopec to form Zhenhai Refining and Chemical production base. Source: Ningbo Ecological Environment Bureau* Disclaimer: the content contained is from public channels such as the Internet and WeChat public accounts. We maintain a neutral attitude towards the views in this article. This article is for reference and communication only. The copyright of the reprinted manuscript belongs to the original author and organization. If there is any infringement, please contact Huanyi world customer service to delete it.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)