Several domestic petrochemical plants stopped production and transportation was blocked.

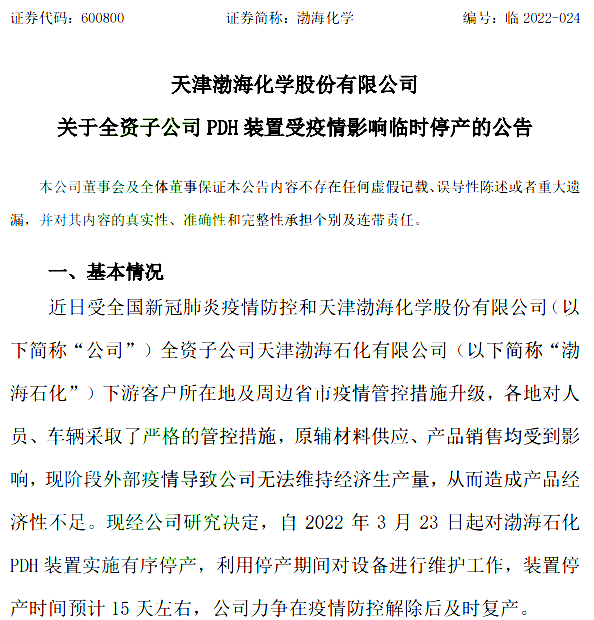

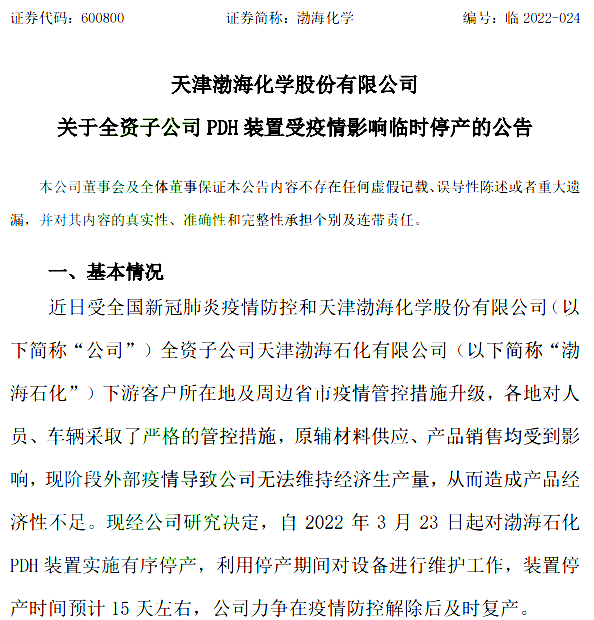

Several petrochemical plants announced the shutdown and shutdown due to the epidemic. This wave of operation seems to be sudden, but in fact it is the decision made by these enterprises after integrating various influencing factors and weighing various advantages and disadvantages, which is similar to the emergency shutdown of more than 20 listed companies at the end of last year. The same is because of the epidemic. The difference is that the current situation is more severe, and the start-up and operation of chemical plants and procurement and sales in various places are basically stagnant. Bohai Chemical: it is said that the current external epidemic causes the wholly-owned subsidiary Bohai Petrochemical to be unable to maintain the economic production, thus causing the lack of product economy. After research, it is decided that the PDH unit of Bohai petrochemical company will be stopped in an orderly manner from March 23. EOL time is expected to be about 15 days, which will have a certain impact on the company's recent operating performance.

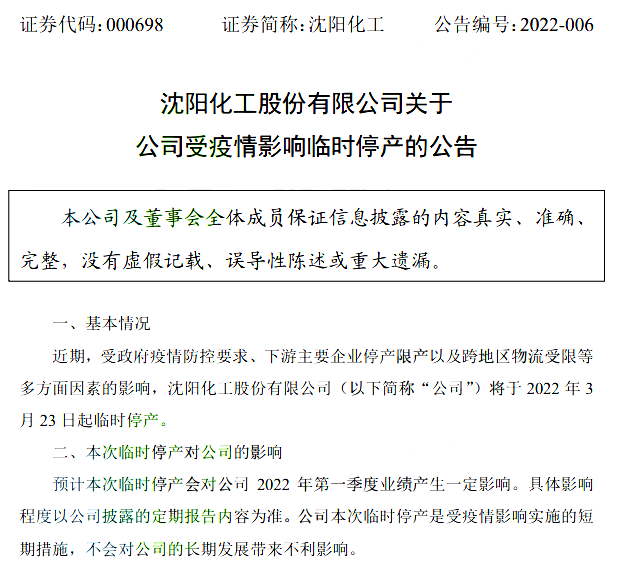

Shenyang Chemical Industry: affected by various factors such as the government's epidemic prevention and control requirements, major downstream enterprises stopped production and limited production, and cross-regional logistics restrictions, enterprises will temporarily stop production from March 23, 2022, it is expected that this temporary shutdown will have a certain impact on the first quarter performance in 2022.

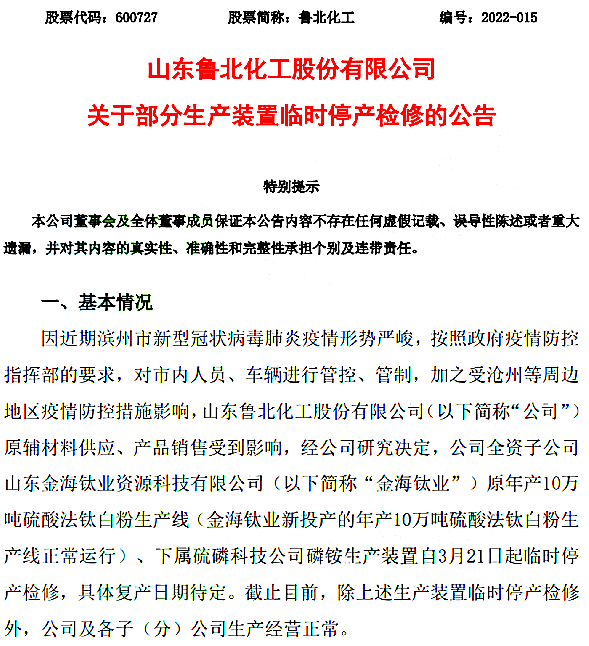

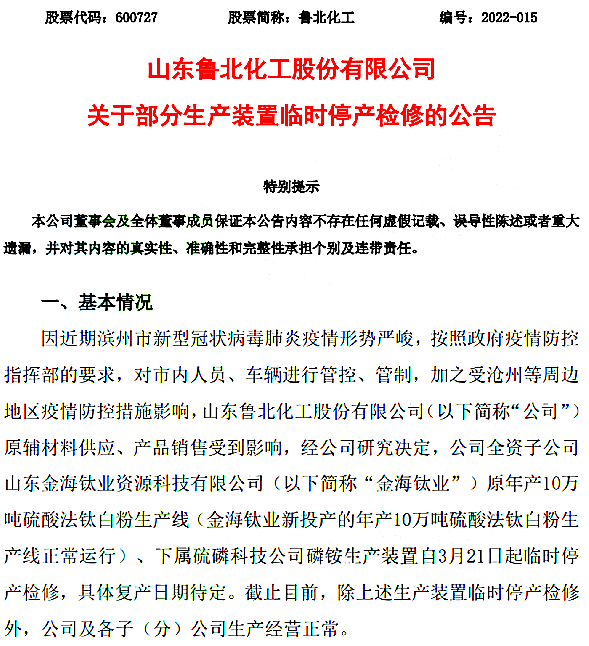

Lubei Chemical Industry: due to the severe situation of the new Crown epidemic in Binzhou city recently, according to the requirements of the government epidemic prevention and control headquarters, personnel and vehicles in the city are controlled and controlled, and affected by the epidemic prevention and control measures in Cangzhou and other surrounding areas, the supply of raw and auxiliary materials and product sales of the company are affected. The original production line of 100,000 tons of sulfuric acid titanium dioxide produced by Jinhai titanium industry, a wholly-owned subsidiary, (the production line of 100,000 tons sulfuric acid titanium dioxide produced by Jinhai titanium industry is running normally), the ammonium phosphate production unit of the subordinate sulfur and phosphorus technology company has been temporarily suspended for maintenance since March 21.

In addition, many petrochemical enterprises also announced that due to the impact of the epidemic on transportation, they reminded everyone to arrange stocking in advance. Qingdao alkali industry said that a large number of foreign vehicles could not pick up goods at the factory on time, and the vehicles delivered to other places were also unable to arrive in many areas, which directly affected the normal delivery of enterprises. Hualu Hengsheng also said that drivers from other places were unwilling to come to pick up goods, local drivers are also struggling with delivery.

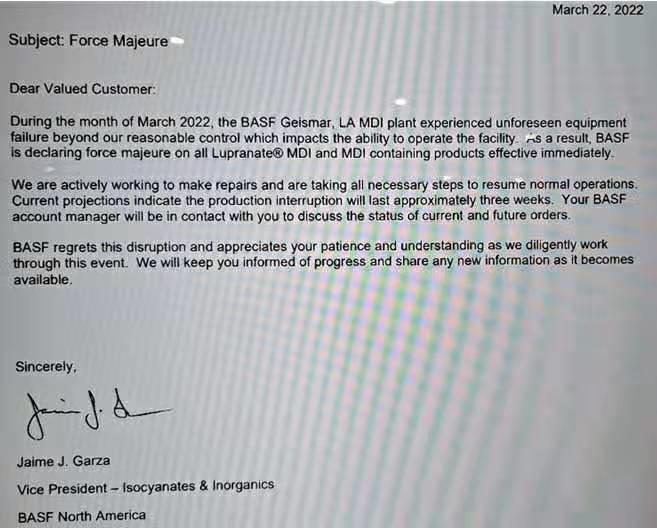

Overseas Force Majeure occurs frequently, and BASF and Mitsui chemistry are affected.

The recent overseas situation is not optimistic either. BASF announced force majeure, Mitsui Chemical closed the factory, and the supply of various chemicals decreased sharply.

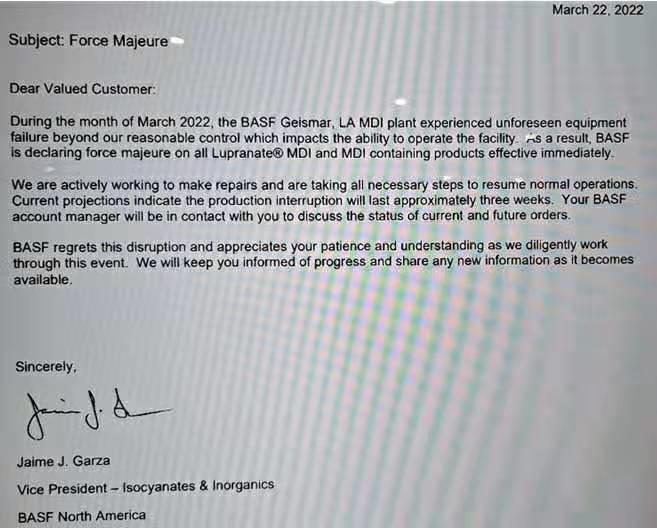

BASF: the 400,000-ton/year MDI unit located in the gasma plant in North America will affect the operation capability of the plant due to unexpected equipment failures. From now on, force majeure shall take effect immediately for all MDI products and products containing MDI components. At present, BASF is actively repairing the equipment. At present, it is predicted that the production interruption will last for about 3 weeks.

United States epoxy resin manufacturer Olin it is advertised that the German factory will stop producing epoxy resin, only because the production cost is too high, the recovery time will be notified separately.

PTA giant mitsui chemistry it is planned to close the purified terephthalic acid (PTA) factory of Japanese Yamato in August 2023, with a production capacity of 400,000 tons/year. The main reason is the decline in the global market and the decrease in domestic demand in Japan.

The energy crisis intensified, the opening of the business was a loss, and the vicious circle of "reducing production"

looking at the shutdown, shutdown and shutdown of petrochemical enterprises above, the main factors are the spread of the epidemic and force majeure, which makes many domestic middle-stream plastic enterprises and chemical enterprises feel anxious. What is more severe is that in addition to the insufficient supply in the upstream and the continuous high price of raw materials, the comprehensive production cost of enterprises is also increasing, and the main influencing factor is the aggravation of the energy crisis.

Affected by the big environment, many petrochemical enterprises were forced to stop production, and some enterprises chose to take the opportunity to overhaul and reduce the load, which was called the initiative to "lie flat. PTA factories have been overhauled more, and the capacity utilization rate has reached a low point within the year.

Yisheng Ningbo2 million tons PTA restart time delayed pending, Yisheng new material two sets of devices maintain a set of semi-operation

fuhaichuang4.5 million tons dropped to 80% in early March

yizeng chemical fiber the 350,000-ton device was stopped at the beginning of March.

Hengli Petrochemical line 4, 2.5 million tons, started maintenance on March 10

yangzi Petrochemical650,000 tons, zhuhai innix the 1.25 million-ton PTA plant is scheduled to be overhauled in late March, and Hengli Petrochemical line 1, Jiaxing petrochemical and other units are scheduled to be overhauled in April.

In the textile industry, weaving factories in Jiangsu and Zhejiang regions have been reducing production and production, and the comprehensive startup load of looms is less than 70%.

It is estimated that the operating rate of some chemical subdivision fields will be reduced by another 10% before and after Qingming Festival. So when more and more middle-stream chemical enterprises choose to actively stop work or passively stop production, can the plastic and chemical industries change their decline in the future and turn into a situation of short supply, whether the "out-of-stock tide" and the following "reduction tide" can ignite the "price increase tide" again is worth waiting and seeing.

* Disclaimer: the content contained is from public channels such as the Internet and WeChat public accounts. We maintain a neutral attitude towards the views in this article. This article is for reference and communication only. The copyright of the reprinted manuscript belongs to the original author and organization. If there is any infringement, please contact Huanyi world customer service to delete it.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)