Read: 463

Time:48months ago

Source:

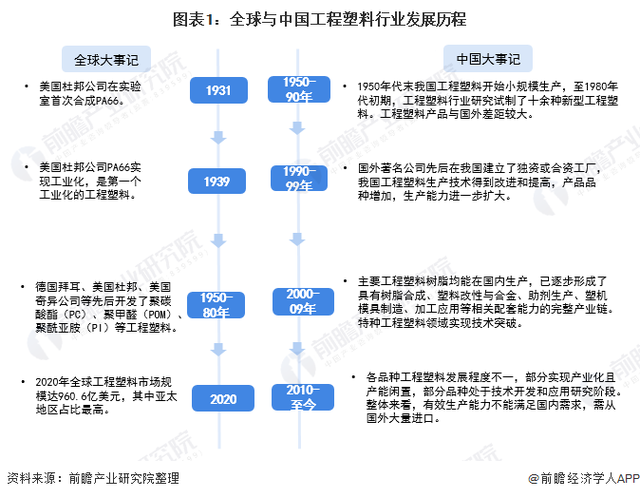

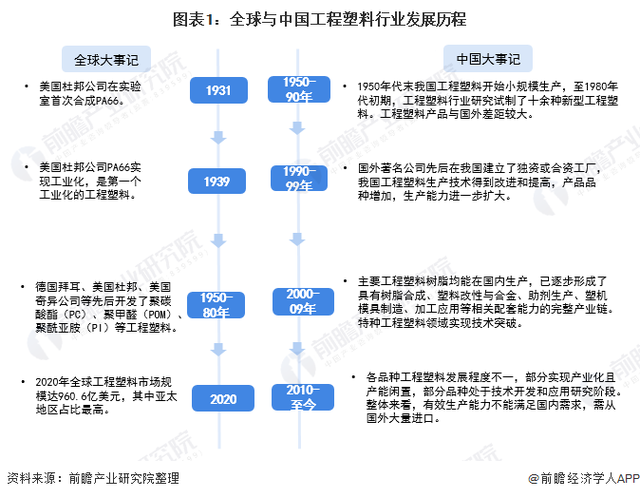

Development History of engineering plastics industry

foreign engineering plastics industry started earlier. In 1931, DuPont Company of the United States synthesized PA66 for the first time in the laboratory. In 1939, PA66 realized industrialization and was the first industrialized engineering plastic. From 1950 to 1980, it was a period of rapid development of research and development in the global engineering plastics industry. Bayer in Germany, DuPont in the United States and strange company in the United States successively developed Polycarbonate (PC), polyoxymethylene (POM) and polyimide (PI). And other engineering plastics. Comparatively speaking, China's engineering plastics started late, but developed rapidly. At present, it has gradually formed a complete industrial chain with related supporting capabilities such as resin synthesis, plastic modification, alloy, processing and application, etc, the scale of the industry continues to expand, and the export continues to grow; The scale of the enterprise continues to grow, and the variety of products continues to increase; The level of science and technology is increasing day by day, and the technical and quality indicators of some products are also close to the advanced level of foreign countries. In recent years, the industrialization development of PPS, PI, PEEK and other special engineering plastics and downstream products has accelerated. Small varieties such as polysulfone, polyaryl Ester and special polyamide are in the stage of technology development and application research, the industrialization process is slow. With the rapid development of automobile, electronics, electrical, communication technology and machinery industry, the demand for engineering plastics with special excellent properties such as high strength, heat resistance and flame retardant has been rapidly improved. At present, the output of engineering plastics in countries with higher industrialization degree such as the United States and Germany is far ahead of the global level, and it is a region with better development of engineering plastics in the world. The world-renowned engineering plastics production enterprises mainly include DuPont, Dow, BASF, Rhodia, Mitsubishi, Emperor and other enterprises. Judging from the enterprise competition pattern of subdivided products, DuPont is the world's largest manufacturer of nylon resin and SABIC Company (after acquiring GE Plastics Group) is the world's largest manufacturer of modified PC and PPO; BASF, Germany, has strong competitiveness in the field of automotive engineering plastics.

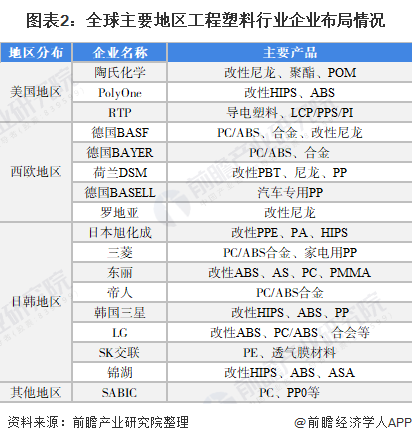

With the rapid development of automobile, electronics, electrical, communication technology and machinery industry, the demand for engineering plastics with special excellent properties such as high strength, heat resistance and flame retardant has been rapidly improved. At present, the output of engineering plastics in countries with higher industrialization degree such as the United States and Germany is far ahead of the global level, and it is a region with better development of engineering plastics in the world. The world-renowned engineering plastics production enterprises mainly include DuPont, Dow, BASF, Rhodia, Mitsubishi, Emperor and other enterprises. Judging from the enterprise competition pattern of subdivided products, DuPont is the world's largest manufacturer of nylon resin and SABIC Company (after acquiring GE Plastics Group) is the world's largest manufacturer of modified PC and PPO; BASF, Germany, has strong competitiveness in the field of automotive engineering plastics. Types of domestic engineering plastics enterprises

in recent years, with the large-scale and scale of newly-built engineering plastic devices in our country, some original small-scale, intermittent devices, backward process routes and lack of competition have gradually withdrawn from the market.

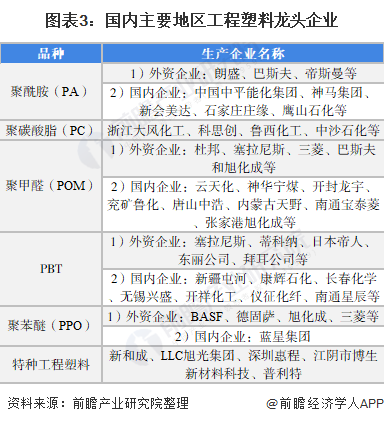

From the perspective of enterprise types, domestic engineering plastics enterprises are mainly foreign-funded and Sino-foreign joint ventures, followed by state-owned, private and other types of enterprises. At present, China's major engineering plastics production enterprises include Shenma Group, China National Blue Star, Yuntianhua and other state-owned enterprises; Meanwhile, DuPont, Bayer, Emperor, mitsubishi and other international well-known manufacturers invest and build factories in China and expand their scale, which is an important participant of engineering plastics enterprises in China; The development of private enterprises such as Tunhe, Jiangyin and Shili in Xinjiang, Deyang in Sichuan is also more prominent. Main production enterprises of engineering plastic PA

judging from the enterprise competition pattern of subdivided products, the global manufacturers of polyamide engineering plastics mainly include Invista, osend, DuPont, BASF, etc. Judging from the domestic competition pattern, domestic PA66 manufacturers mainly include inweida, Shenma Group, Jiangsu Huayang, etc.; in terms of PA6, major domestic enterprises include Zhongjin new materials, Haiyang chemical fiber, Luxi Chemical Industry, Xinhui Meida, etc.

Engineering Plastics major PC manufacturers

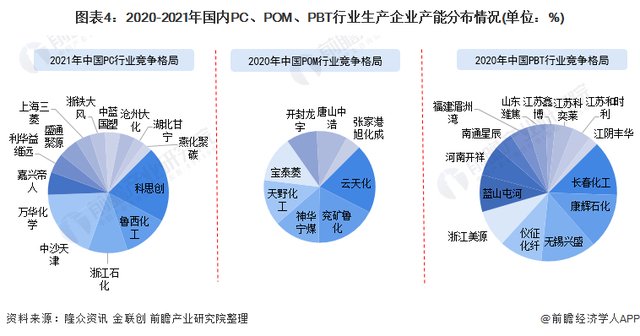

at present, PC production technology is mastered in a few major international factories. In recent years, although China has successively put into production by domestic manufacturers such as Zhejiang Gale chemical industry and Luxi Chemical Industry, however, there are still many gaps between its production technology and international large factories. Judging from the capacity of major domestic PC production enterprises, the main production enterprises include kesichuang, Luxi Chemical Industry, Zhejiang Petrochemical industry, etc.

Engineering Plastics POM main production enterprises

international POM production is mainly concentrated in the United States, Germany, Japan, Holland and other developed countries. Domestic POM enterprises mainly introduce technology. Judging from the capacity of major domestic POM production enterprises, the main production enterprises include Yuntianhua, Shenhua Ning coal, Tianye chemical industry, etc. Engineering Plastics main PBT production enterprises

PBT manufacturers around the world are mainly concentrated in the United States, Western Europe, Japan and South Korea. The main manufacturers are Celanese, Tikona, Japanese Emperor, Dongli company, Bayer company, etc. Judging from the capacity of major domestic PBT production enterprises, the main production enterprises include Changchun Chemical Industry, Kang Hui petrochemical, Wuxi Xingsheng, Yizeng chemical fiber, Zhejiang Hoyu, Lanshan Tunhe, etc.

Engineering Plastics main production enterprises of PPO

PPO is one of the engineering plastics with the highest dependence on China's imports, which has been mainly imported for a long time. At present, there are only five enterprises in the world that truly master the industrial production technology of 10,000-ton PPO, including Saudi Basic Industry Corporation (SABIC), Asahi kasu, Japan, Mitsubishi Gas Chemistry, nantong XingChen Synthetic Materials Co., Ltd. and Xinbao New Materials Co., Ltd. under China Blue Star. Technical difficulties of domestic engineering plastics

at present, the industrialization of PI, PPA, LCP, PEEK and other varieties has been preliminarily realized in China, but there is a big gap compared with the advanced level abroad, and the whole industry is still in the early stage of development, there are many difficulties to be solved in the process of some technological industrialization. Major global and domestic manufacturers of special engineering plastics are as follows: research and development direction of engineering plastics

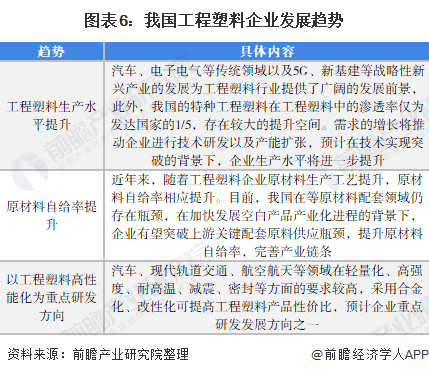

in recent years, with the continuous technological and product innovation of related enterprises in the industry, the localization of engineering plastics has accelerated. Under the background of the enterprise's technology research and development and the downstream application industry of engineering plastics, especially the accelerated development of strategic emerging industries, it is expected that the self-sufficiency rate of raw materials and the production level of engineering plastics products will continue to improve. In addition, with the improvement of light weight, high strength, high temperature resistance, shock absorption, sealing and other requirements in the fields of automobile, modern rail transit, aerospace and so on, high performance may be the key research and development direction for enterprises. Source: prospective economist* Disclaimer: the content contained is from public channels such as the Internet and WeChat public accounts. We maintain a neutral attitude towards the views in this article. This article is for reference and communication only. The copyright of the reprinted manuscript belongs to the original author and organization. If there is any infringement, please contact Huanyi world customer service to delete it.

Mainly

Mainly

Polyurethane

Polyurethane

Fine Chemical

Fine Chemical

.png)